Spring fatigue test device

A fatigue test and detection technology, applied in the field of mechanical equipment, can solve the problems of long test time, inability to timely feedback automatic operation, and low frequency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

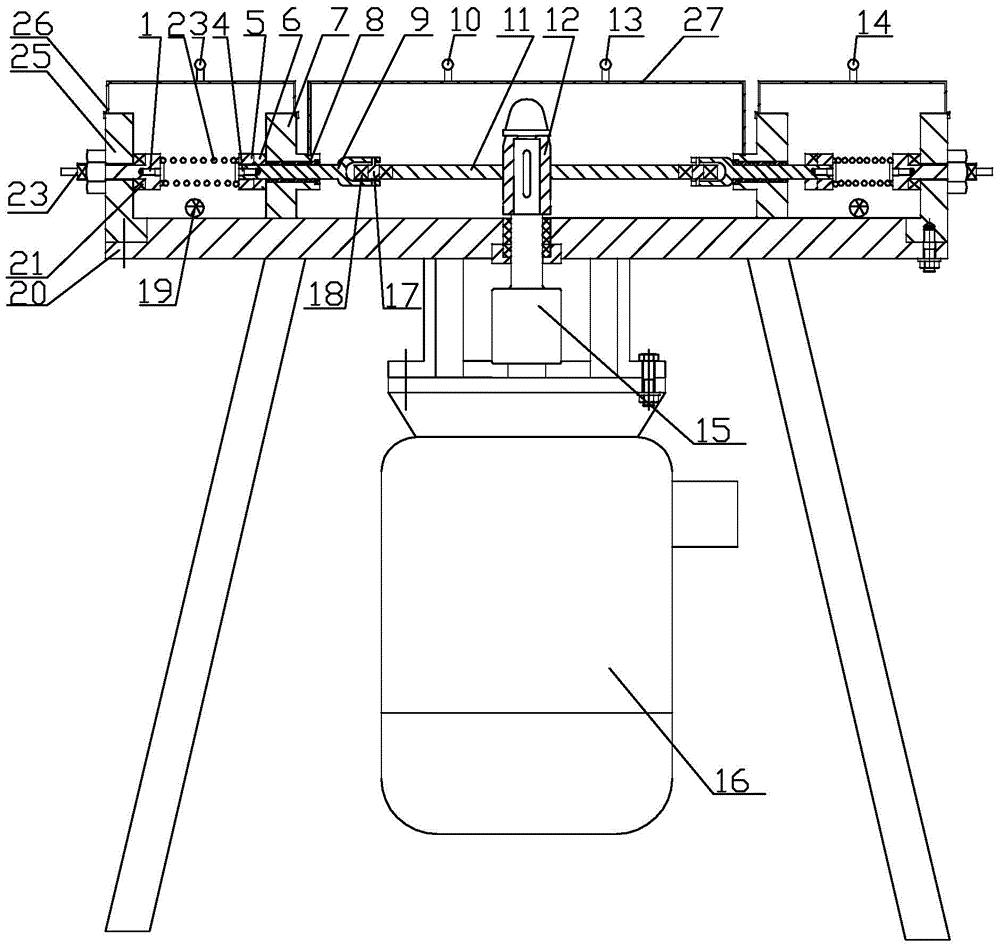

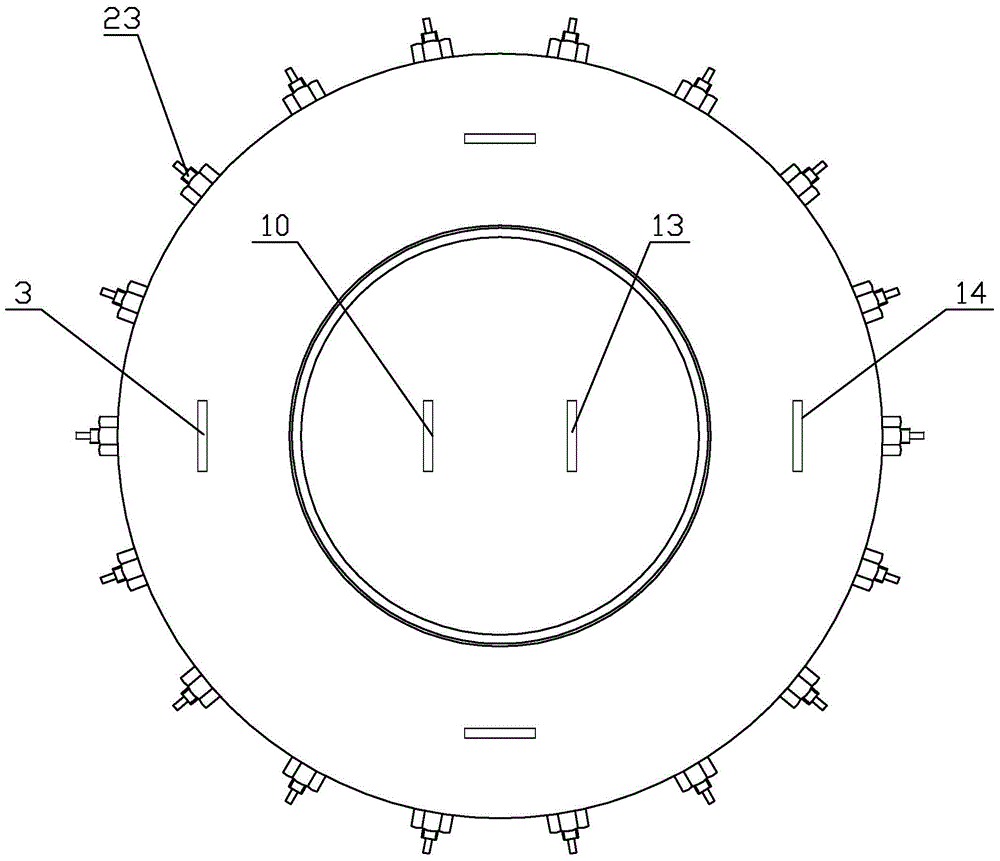

[0017] In order to make the content of the present invention more clearly understood, the present invention will be further described in detail below based on specific embodiments and in conjunction with the accompanying drawings.

[0018] Such as figure 1 , 2 Shown, a kind of spring fatigue testing device, it comprises pressure sensor 21, control panel, support body, cam 11 and the transmission mechanism that drives cam 11 to rotate and at least one spring holding mechanism, and spring holding mechanism includes follower piston assembly and The base assembly and the follower piston assembly are slidingly fitted on the support body. One end of the follower piston assembly is in active contact with the cam 11 so that when the cam 11 rotates, the follower piston assembly is pushed to move relative to the support body. The detected spring 2 is installed on the follower Between the other end of the piston assembly and the base assembly, the pressure sensor 21 is installed on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com