Arrayed Waveguide Grating Wavelength Division Multiplexer

A technology of arrayed waveguide grating and wavelength division multiplexer, which is applied in the directions of light guide, optics, instruments, etc., can solve the problems such as easy deformation of temperature compensation rod or temperature compensation sheet, poor structural stability, complex mechanical structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

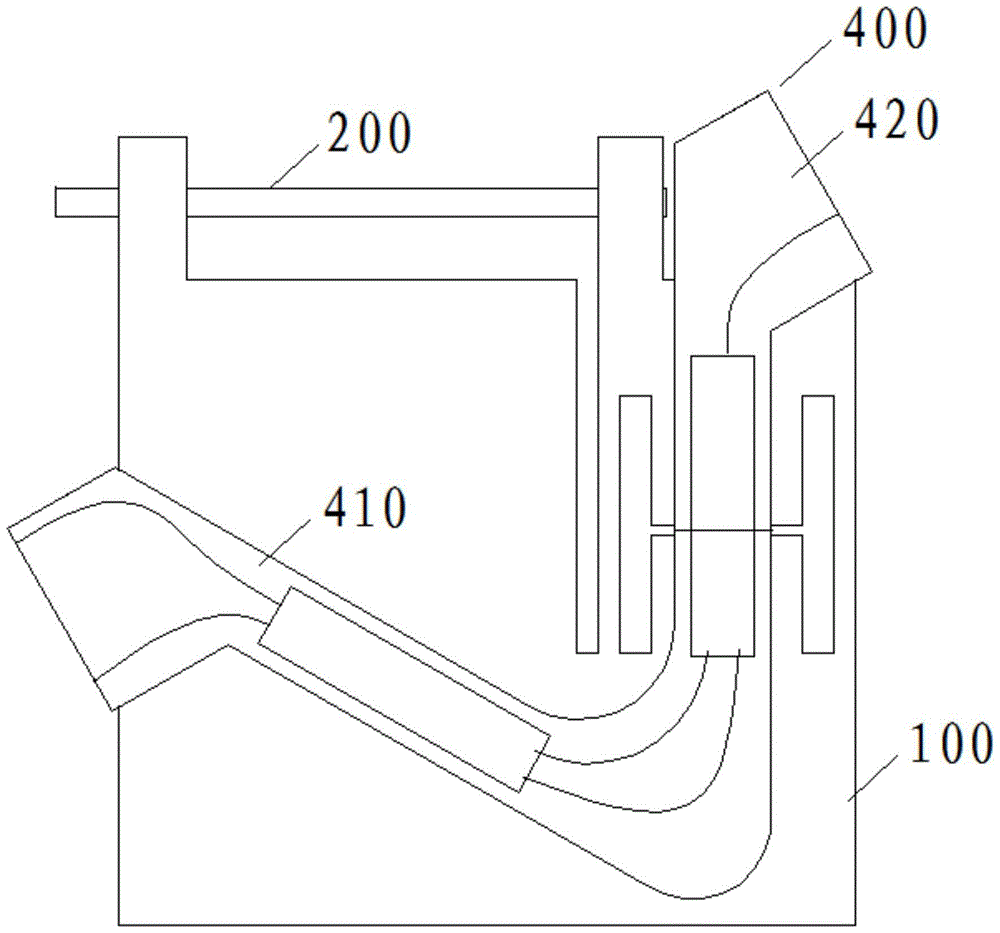

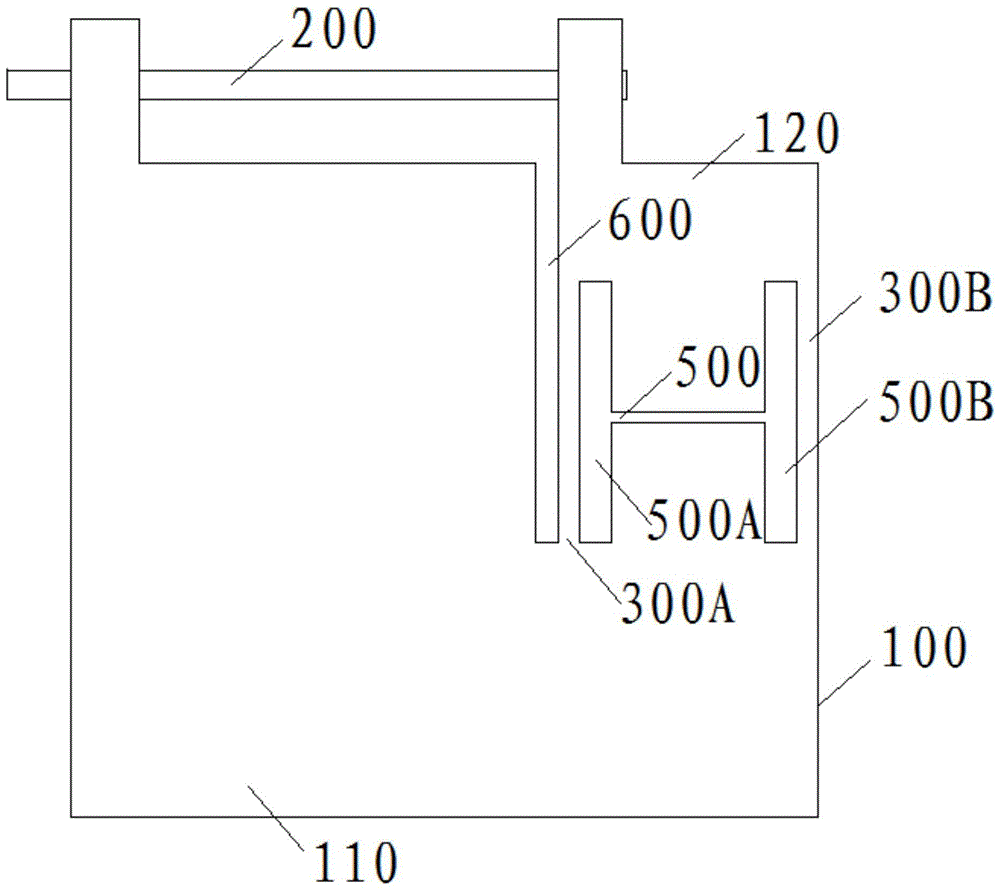

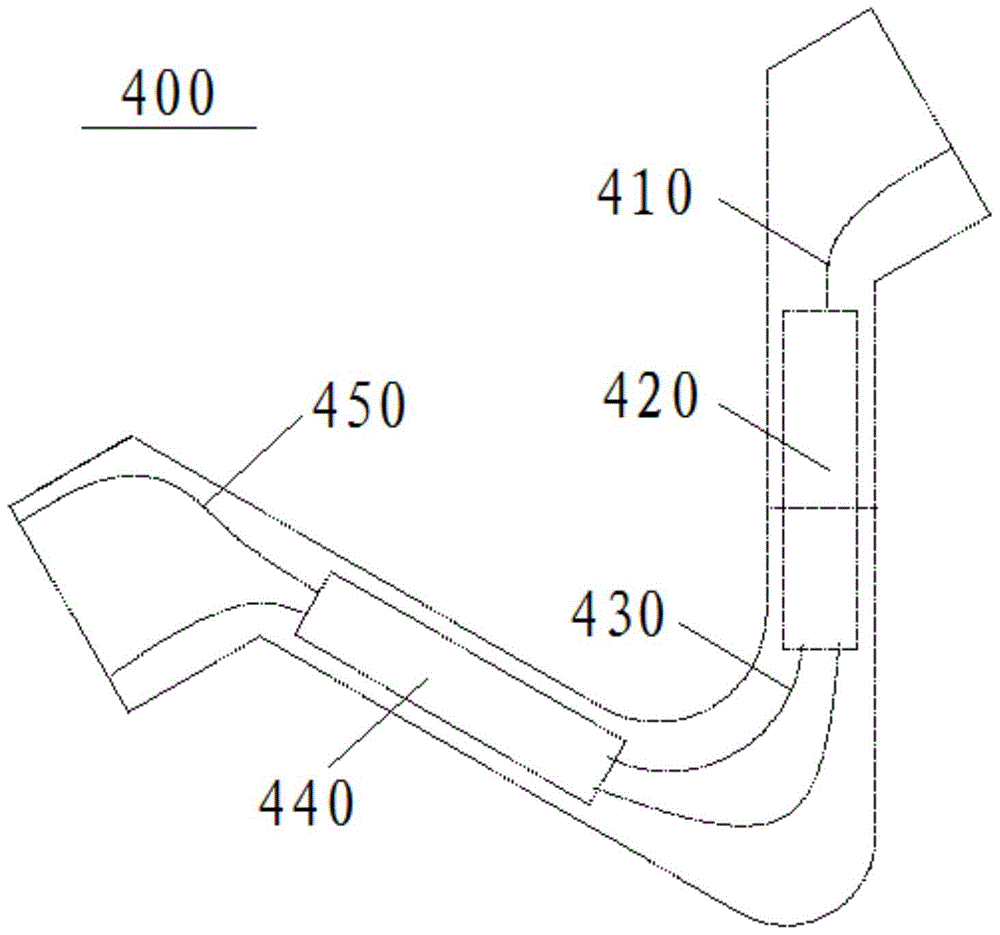

[0023] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0024] An arrayed waveguide grating wavelength division multiplexer includes a base plate, a telescopic part, a support part and an arrayed waveguide grating chip, and the telescopic part expands and contracts as the temperature changes.

[0025] The arrayed waveguide grating chip is pasted on the substrate, the substrate and the arrayed waveguide grating chip are cut separately, the substrate is cut into a first substrate and a second substrate, and a cutting slit is formed between the first substrate and the second substrate, and the arrayed waveguide grating chip is cut Cutting and separating into a first part of chips and a second part of chips, the telescopic part connects the first substrate and the second substrate, the angle between the telescopic part and the cutting slit is not equal to 90°, and the supporting part conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com