Optimizing Method of Exposure Auxiliary Graphics

A technology for assisting graphics and optimization methods, applied to the photographic process of patterned surfaces, originals for photomechanical processing, optics, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

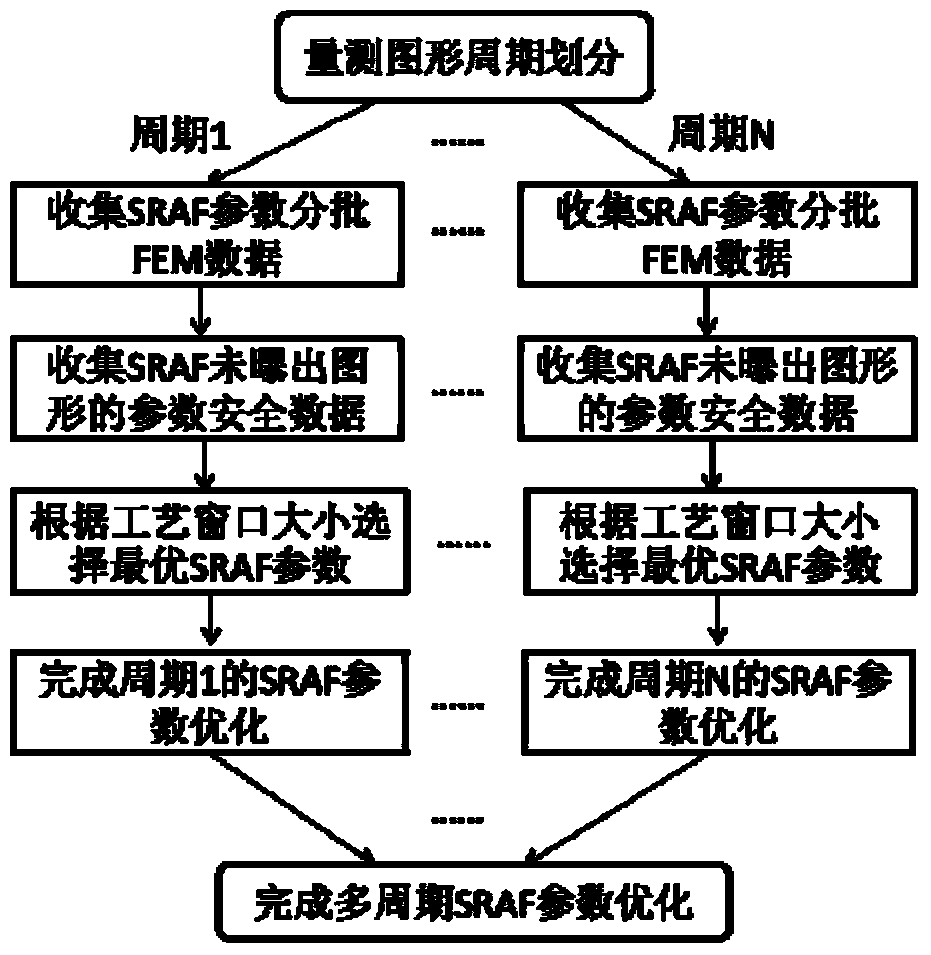

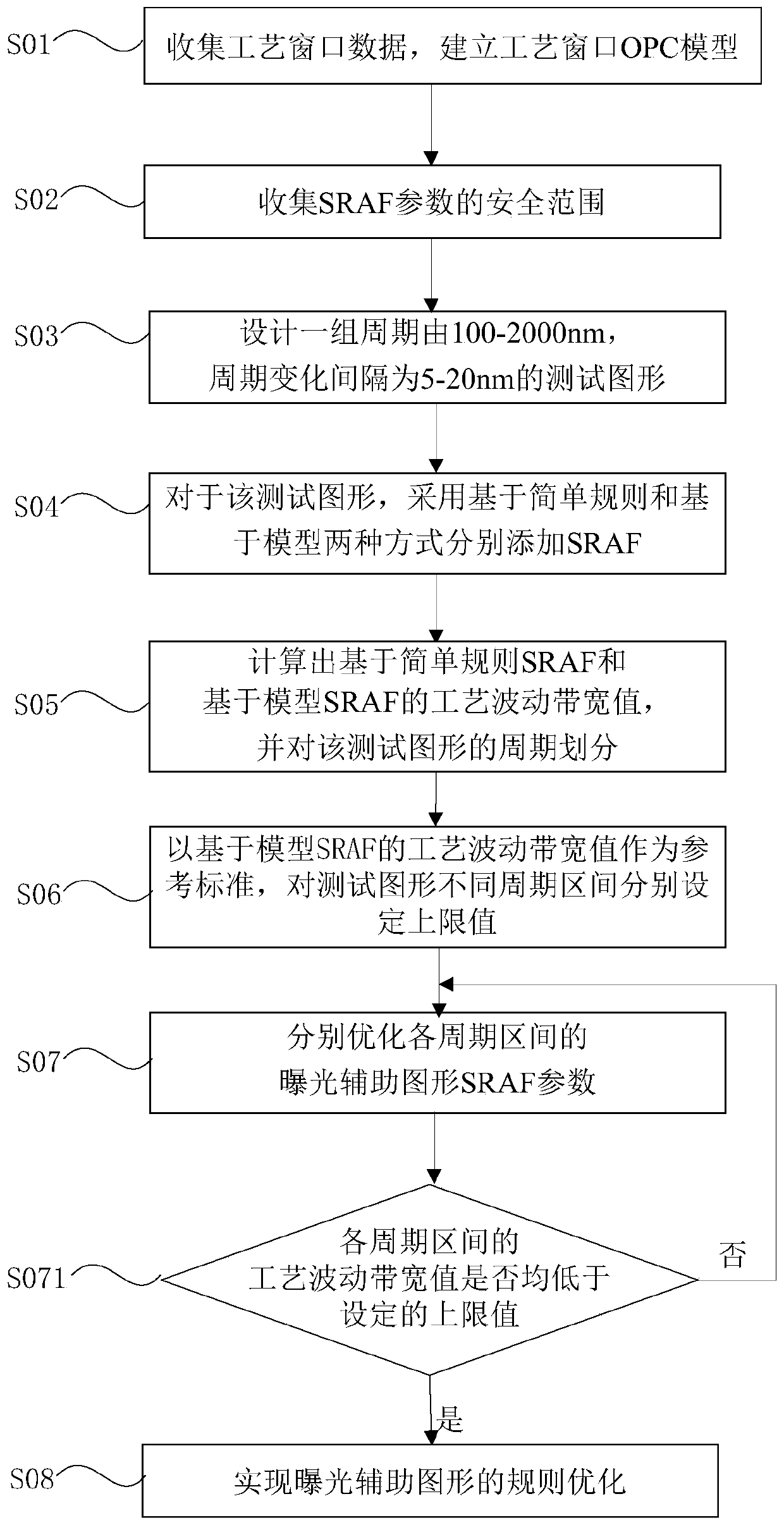

[0033] see figure 2 , the optimization method of the exposure assistance figure of the present embodiment comprises the following steps:

[0034] Step S01, collect OPC test pattern data of multiple energy and focal depth conditions within the process window, and establish an OPC model of the process window.

[0035] Step S02 , collecting a safe range of SRAF parameters, where the safe range of parameters is a safe range of parameters of the SRAF in which no pattern is exposed within the process window. For example, when the width of the exposure auxiliary patterns is 20-45nm, the distance between the exposure auxiliary patterns and the main pattern is 50-100nm, and the distance between the exposure auxiliary patterns is 50-100nm.

[0036] Step S03 , designing a group of 1D line or 2D hole test patterns with a period of 100-2000nm and a period change interval of 5-20nm according to the pattern characteristics of the lithography layer.

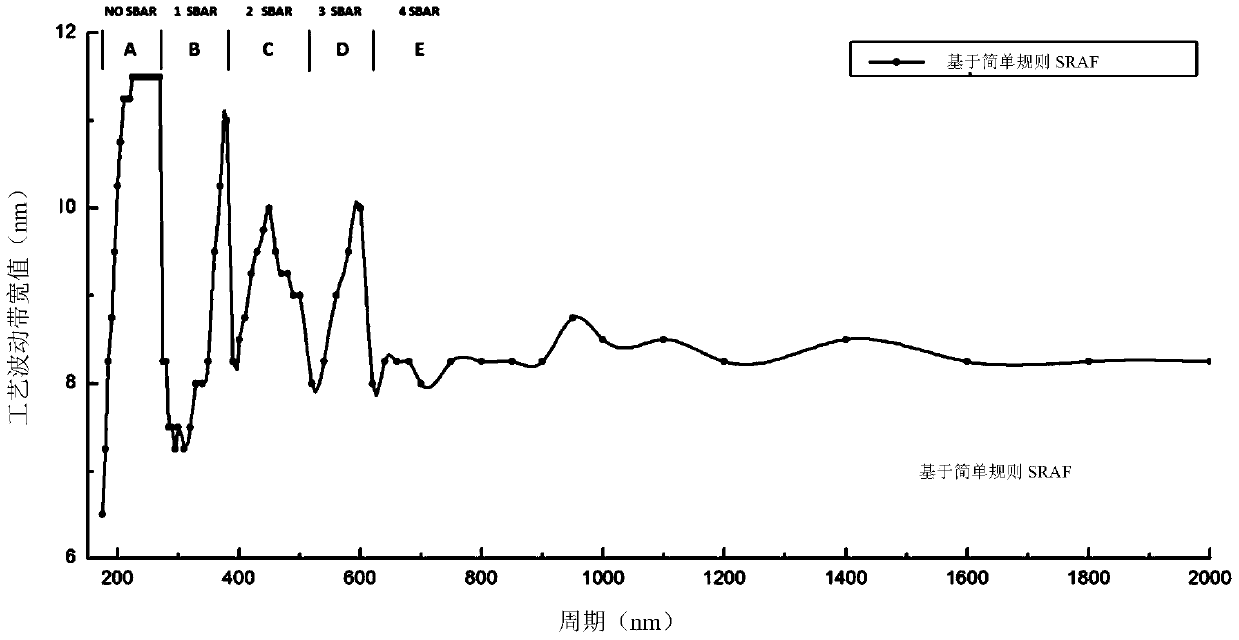

[0037] In step S04, for the test patte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com