Five-stage S-curve acceleration and deceleration control method based on particle swarm optimization algorithm

A particle swarm optimization, acceleration and deceleration control technology, applied in the direction of electric speed/acceleration control, etc., can solve the problems of reducing the service life, affecting the safe and reliable operation of the system, and increasing the fatigue damage of the shaft.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

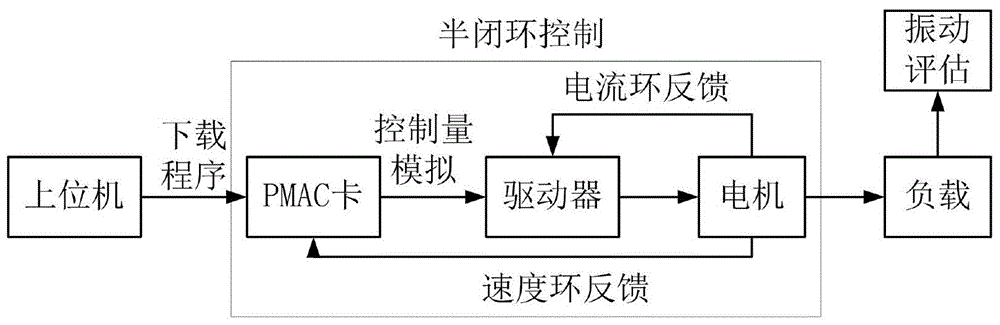

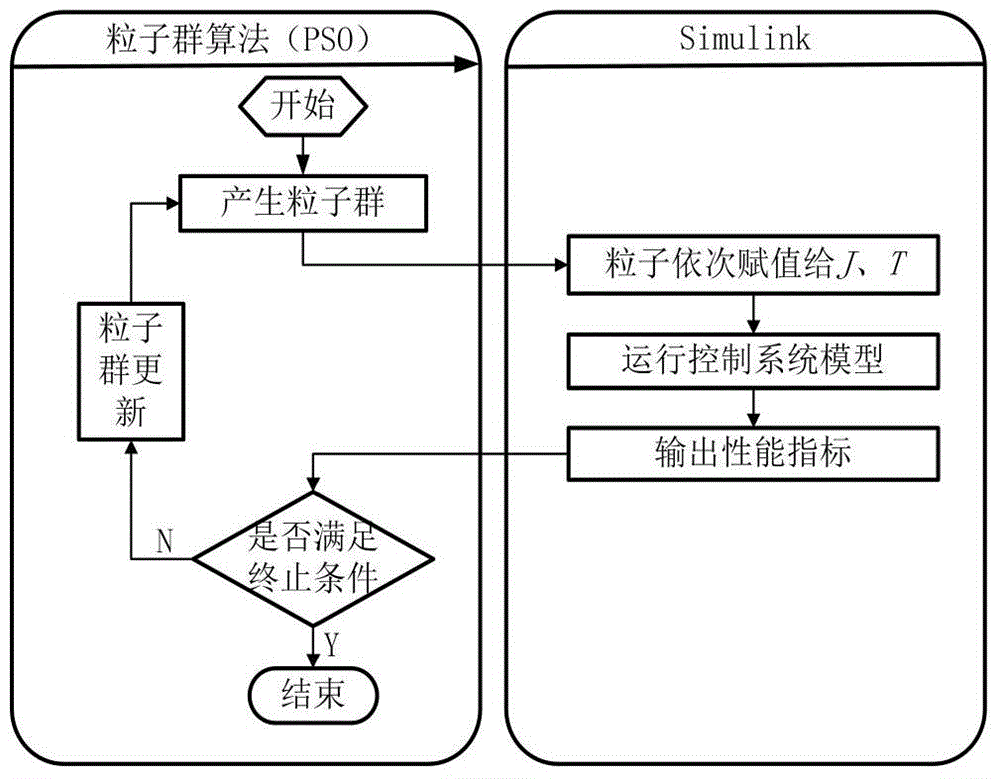

[0034] The present invention is a five-stage S-curve acceleration and deceleration control method based on particle swarm optimization, and its control flow refers to figure 1 , for the T-shaped input speed curve of the mechanical system, drive its motion, collect the speed input and output curve, and identify the system transfer function. According to the transfer function, the particle swarm optimization algorithm is used to optimize the parameters of the five-stage S-curve offline, and then the five-stage S-curve is used for semi-closed-loop control of the mechanical system, which greatly suppresses the torsional vibration of the system.

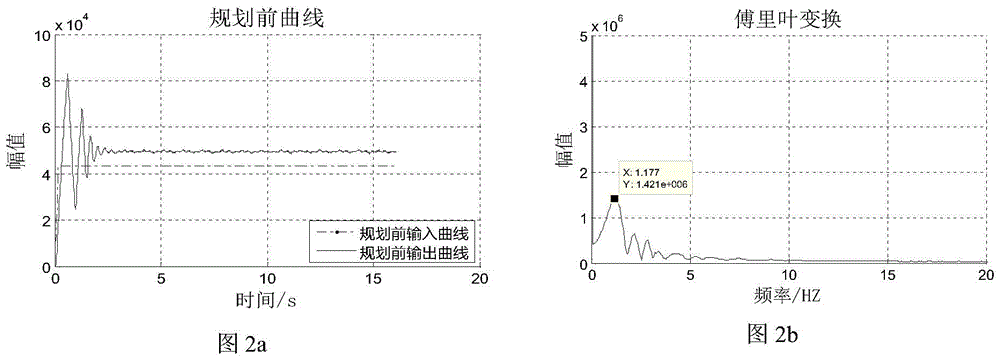

[0035] figure 2 a is the input-output curve under the T-shaped input speed curve. It can be seen that when the target output value is 50,000 pulses / s, the vibration peak value reaches 83,000 pulses / s, the maximum overshoot is 86%, and the adjustment time is 1.8s. According to the input speed curve and the output speed curve, the transfe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com