Embedded-type touch screen and display device

A built-in touch screen, integrated technology, applied in optics, instruments, electrical and digital data processing and other directions, can solve the problems of touch screen touch failure, affecting touch screen display, etc., to prevent interference and damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

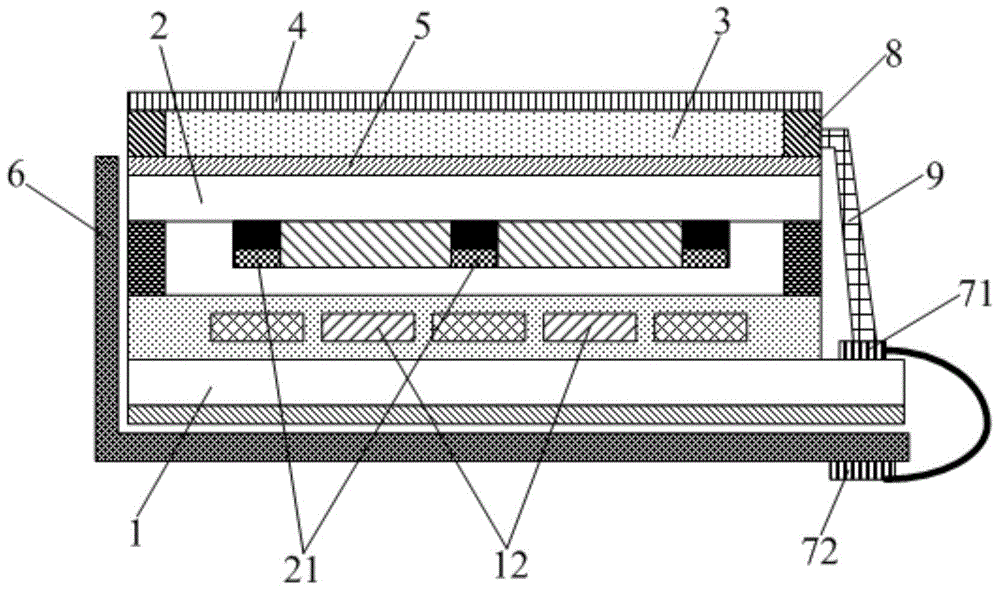

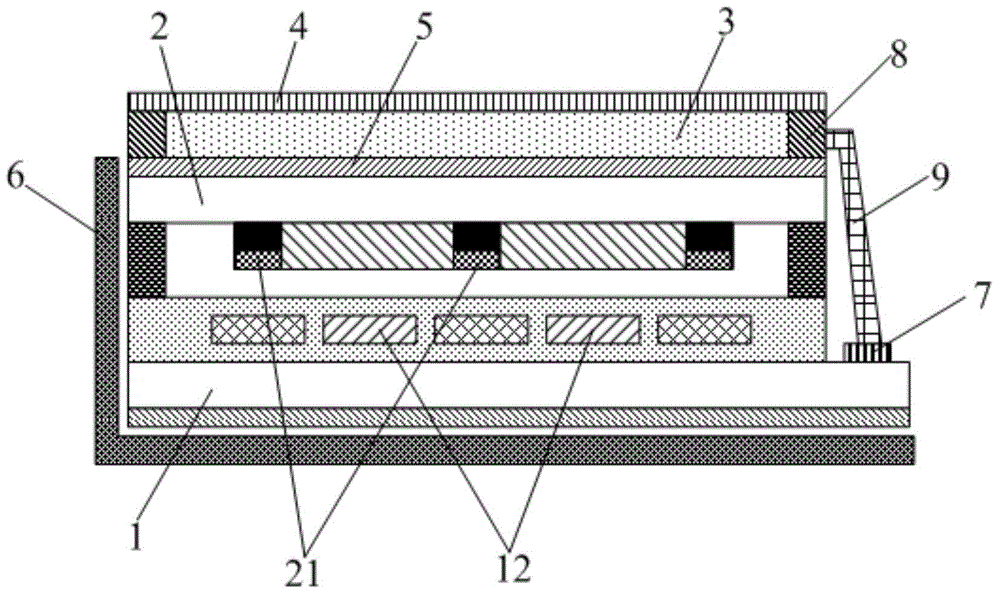

[0034] This embodiment provides an embedded touch screen, such as figure 1 As shown, it includes an array substrate 1 and a color filter substrate 2 that are arranged oppositely, and the touch electrodes (that is, the driving electrodes 12 and the sensing electrodes 21) are arranged between the array substrate 1 and the color filter substrate 2. 2, the electrostatic release layer 3 on the side away from the array substrate 1, the electrostatic release layer 3 is a transparent conductive layer with a sheet resistance above the megohm level.

[0035] Wherein, the sheet resistance of the electrostatic discharge layer 3 ranges from greater than or equal to 1MΩ to less than or equal to 1kMΩ. The electrostatic release layer 3 with the resistance value of the square resistance can discharge the static electricity well, and will not shield the touch signal of the touch screen, so that the touch screen can well prevent the interference or destruction of static electricity, and can Tou...

Embodiment 2

[0047] This embodiment provides an embedded touch screen. The difference from Embodiment 1 is that the electrostatic discharge layer of the touch screen does not use insulating optical adhesive materials doped with conductive particles, but uses other materials that meet the requirements of the square resistance value of megohms. Transparent conductive materials above the level, for example: transparent conductive materials formed by doping PEDOT (polyethylenedioxythiophene) particles in insulating resin materials, or transparent conductive materials formed by doping indium antimony oxide particles in SiO2 insulating materials etc., these transparent conductive materials can be formed on the substrate by coating. Among them, the PEDOT particles or the indium antimony oxide particles are also connected by molecular formula or chemical bond, so that the static electricity accumulated on the static electricity release layer 3 can be conducted away.

[0048] In this example, if ...

Embodiment 3

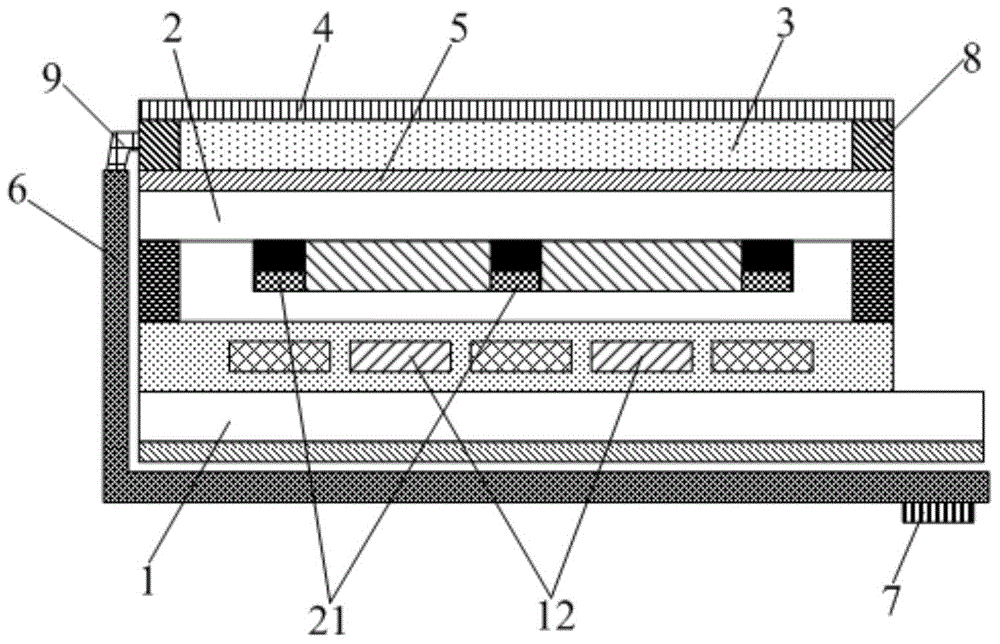

[0051] This embodiment provides an embedded touch screen, and the difference from Embodiment 1-2 is that, as Figure 5 As shown, the touch screen also includes an adhesive layer 10, the upper polarizer 5, the adhesive layer 10 and the electrostatic release layer 3 are sequentially laminated on the color filter substrate 2, the cover plate 4 is covered on the electrostatic release layer 3, and the adhesive The layer 10 can bond the cover plate 4 and the color filter substrate 2 together. Wherein, the electrostatic discharge layer 3 is directly coated on the top of the cover plate 4, and the adhesive layer 10 is a non-conductive layer having an adhesive effect.

[0052] In addition, in this embodiment, the first ground terminal 71 is connected to the electrostatic discharge layer 3 through the conductive silver paste 9 and the conductive tape 11, and the conductive tape 11 is arranged on the edge area of the in-cell touch screen corresponding to the non-touch display area. In...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com