Method for dehumidifier welding blocking self detecting

A dehumidifier and welding blocking technology, which is applied in the detection of faulty computer hardware, etc., can solve problems such as pipeline welding blocking, component damage, and product unusability, and achieve the effects of reducing burden, improving efficiency, and reducing product damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

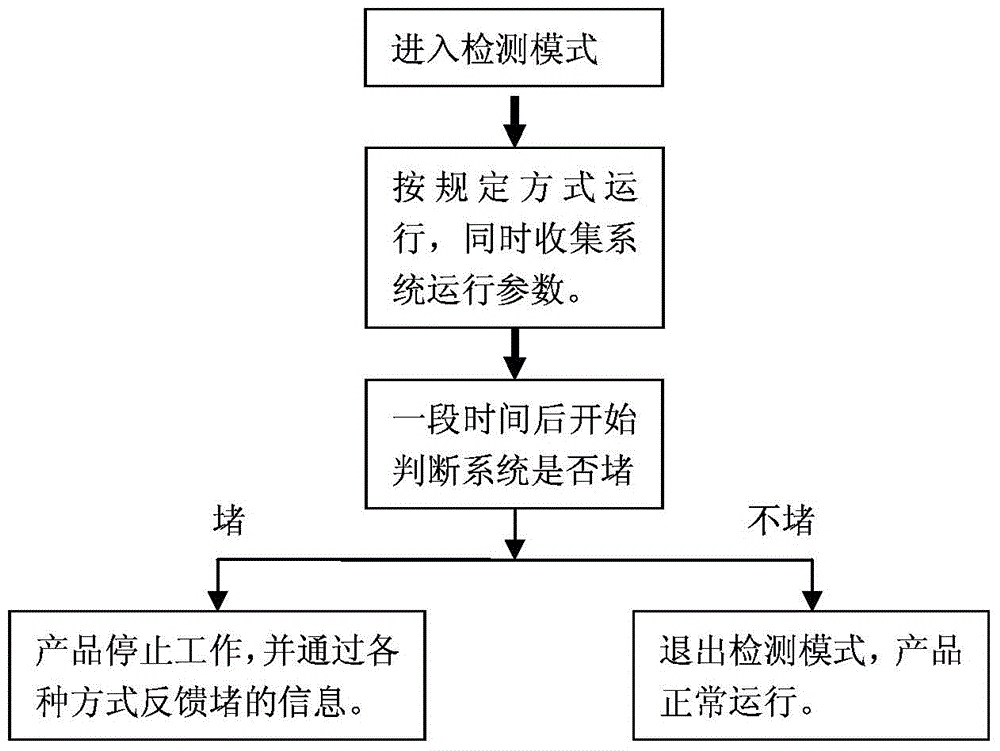

[0032] Combine below figure 1 , the embodiment of the inventive method is described in detail:

[0033] First of all, this set of detection methods is a set of methods for controlling product quality during the production process. After-sales products cannot appear during normal operation, so this method is to control the dehumidifier to enter the welding plugging self-inspection mode through some special operations. Among them, the special commands include the commands formed by the combination of various buttons, and also include remote control and other ways to allow the controller to receive a signal to enter the detection mode.

[0034] Preferably, in step 1, the dehumidifier can only be controlled to enter the welding plugging self-check mode when the power-on time of the product is less than the first set time th1. That is, the instruction to enter the detection mode is related to the power-on time of the product, and must be carried out within h1 seconds. Among them,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com