Electronic component lead

A technology of electronic components and lead wires, which is applied in the field of wires, can solve problems such as fire, leakage, and fire, and achieve the effects of long service life, good conductive effect, and avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

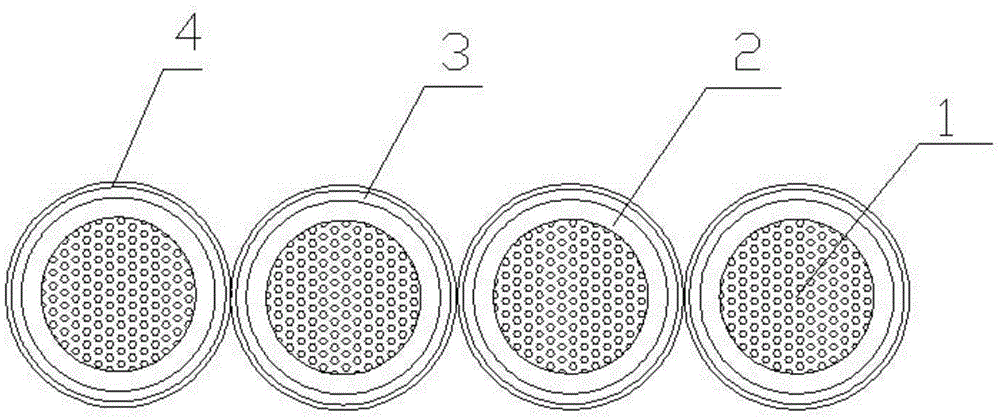

[0017] to combine figure 1 The lead wire of an electronic component shown includes four conductors 1, the conductors 1 are arranged side by side, the outer layer of the conductor 1 is provided with a layer of polyvinyl chloride insulating layer 3, the thickness of the polyvinyl chloride insulating layer 3 is 0.38mm, and the conductor 1 is plated Tin-copper material, between the conductor 1 and the insulating layer 3, there is a covering layer 2 composed of overlapping and wrapping Sike tape, the thickness of the covering layer 2 is 0.8mm, and a waterproof layer 4 is arranged outside the insulating layer 3, the waterproof layer 4 is added with 12% flame retardant material, and the waterproof layers 4 are connected with each other, and the thickness thereof is 0.2mm.

Embodiment 2

[0019] to combine figure 1 The lead wire of an electronic component shown includes four conductors 1, the conductors 1 are arranged side by side, the outer layer of the conductor 1 is provided with a layer of polyvinyl chloride insulating layer 3, the thickness of the polyvinyl chloride insulating layer 3 is 0.33mm, and the conductor 1 is plated Tin-copper material, between the conductor 1 and the insulating layer 3, there is a covering layer 2 composed of overlapping and wrapping Sike tape, the thickness of the covering layer 2 is 0.5mm, and there is a waterproof layer 4 outside the insulating layer, the waterproof layer 4 8% flame retardant material is added, and the waterproof layers 4 are connected with each other, and the thickness thereof is 0.05mm.

Embodiment 3

[0021] to combine figure 1 The lead wire of an electronic component shown includes four conductors 1, the conductors 1 are arranged side by side, the outer layer of the conductor 1 is provided with a layer of polyvinyl chloride insulating layer 3, the thickness of the polyvinyl chloride insulating layer 3 is 0.35mm, and the conductor 1 is plated Tin-copper material, between the conductor 1 and the insulating layer 3, there is a covering layer 2 composed of overlapping wrapping of Sekke tape. 9% flame retardant material is added, and the waterproof layers 4 are connected with each other, with a thickness of 0.12mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com