Metallic shield type woven reinforced rubber jacketed flexible cable of coal cutter

A metal shielding and reinforced technology, applied in the direction of insulated cables, bendable cables, cables, etc., can solve the problems of reducing service life, cables are easily damaged, etc., and achieve the effect of increasing service life and high extrusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The technical solutions of the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings of the present invention.

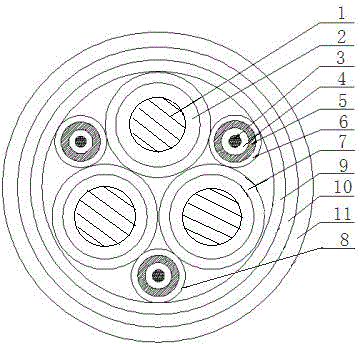

[0015] Such as figure 1 As shown, a metal shielded braided reinforced rubber-sheathed soft cable for a coal mining machine disclosed by the present invention includes a sheath and several power cores and control cores wrapped in the sheath and twisted with each other. The sheath includes an inner sheath 9, an outer sheath 11 and a reinforcement layer 10 located between the inner sheath 9 and the outer sheath 11, the reinforcement layer 10 is braided by multiple strands of high-strength fibers, the The power line core includes a power line core conductor 1, a power line core insulating layer 2 and a power line core shielding layer 7 coated on the outside of the power line core conductor 1, and the control line core includes a control line core conductor 3. The outside of the control c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com