Multi-tab lithium battery core and welding method of multi-tab lithium battery tab

A tab welding and lithium battery technology, applied in battery pack parts, circuits, electrical components, etc., can solve problems such as unfavorable battery production, tab fall off, tab breakage or damage, etc., to solve the problem of battery performance degradation or failure. Use, prevent the pole ear from falling off, and improve the effect of the pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

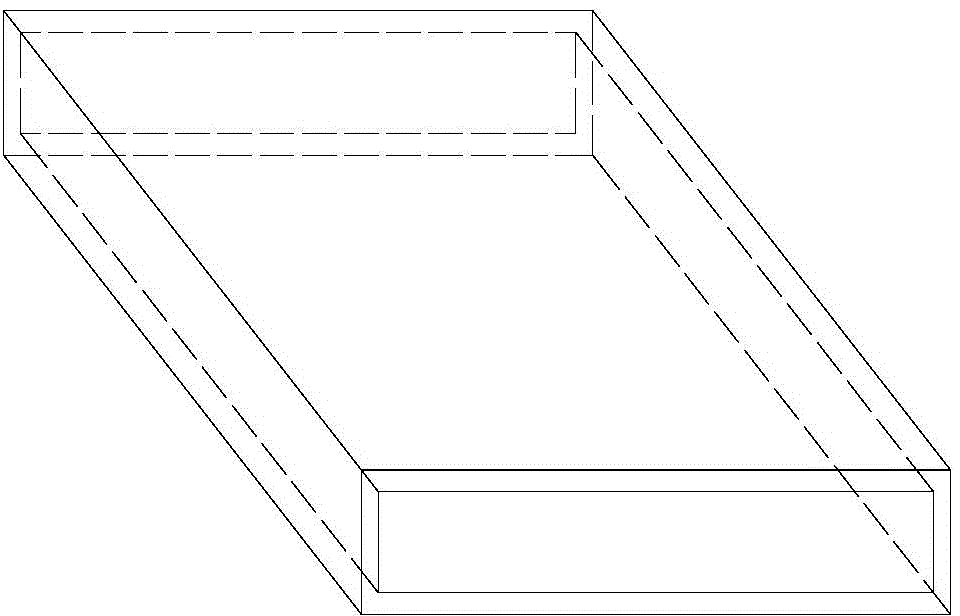

Image

Examples

Embodiment 1

[0021] An embodiment of the present invention provides a multi-tab lithium battery tab welding method, which includes the following steps:

[0022] S1: Set the copper flat ring and the aluminum flat ring on the negative ear and the positive ear of the lithium battery core respectively;

[0023] S2: pre-press the winding core of the copper flat ring and the aluminum flat ring, so that the copper flat ring and the aluminum flat ring are connected firmly with the winding core respectively;

[0024] S3: Place the negative lead-out wire and the positive lead-out wire on the top cover of the battery at the centers of the copper flat ring and the aluminum flat ring respectively;

[0025] S4: Weld the central positions of the copper flat ring and the aluminum flat ring described in S3, so that the tabs on which the copper flat ring and the aluminum flat ring are pressed are welded together with the lead wires of the battery top cover.

[0026] The present embodiment provides that the...

Embodiment 2

[0031] A multi-tab lithium battery winding core, which includes a negative tab and a positive tab, and the negative tab and the positive tab are respectively connected to electrode lead wires on the battery top cover;

[0032] The negative electrode earmuff is provided with a copper flat ring matching it, and the positive electrode earmuff is provided with an aluminum flat ring sleeve matching it. The central position of the flat ring sleeve is welded together with the negative pole lug and the positive pole lug.

[0033] The forming process of the multi-tab lithium battery core provided in this embodiment is the same as that in Embodiment 1.

Embodiment 3

[0035] Firstly, take 50 roll cores of the battery lead wires to be welded, 50 of which are welded with the traditional welding method, and the other 50 are welded with the multi-tab lithium battery tab welding method provided in Example 1. pinout.

[0036] The process of welding the lead wires of the tabs by adopting the multi-tab lithium battery tab welding method provided in Example 1 is as follows:

[0037] S1: Put 0.2mm thick copper flat rings and aluminum flat rings on the negative tabs and positive tabs of the 50 lithium battery cores respectively;

[0038] S2: pre-press each winding core with the flat ring set, so that the connection between the flat ring and the winding core is stable, and the flat ring is prevented from falling off;

[0039] S3: Put the electrode leads on the top cover of each battery in the center of the return ring;

[0040] S4: Weld the center position described in S3 with the traditional overfrequency welding technology, so that each lug with a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com