Aviation blade machining method based on error compensation

A technology of error compensation and processing method, applied in metal processing equipment, manufacturing tools, other manufacturing equipment/tools, etc., can solve problems such as low processing efficiency, low precision, easy deformation, etc., to improve processing efficiency, improve work efficiency, Effect of reducing milling error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

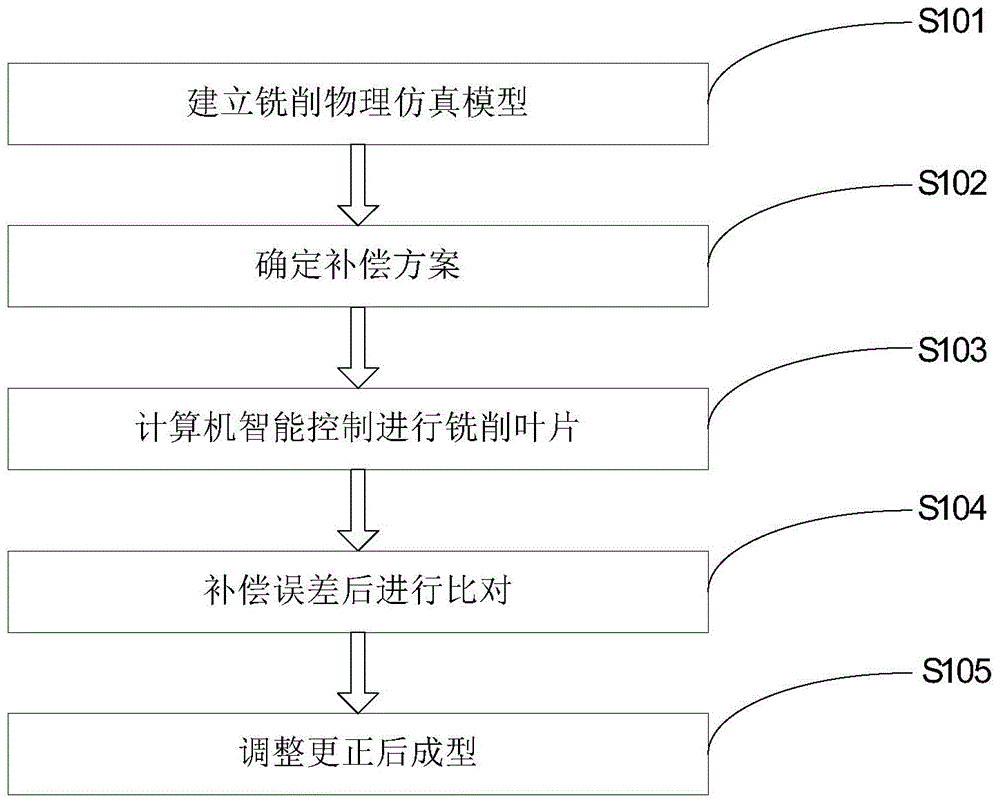

[0019] The present invention includes establishment of milling physical simulation model S101, determination of compensation scheme S102, computer intelligent control for milling blades S103, comparison after compensation for errors S104, shaping after adjustment and correction S105;

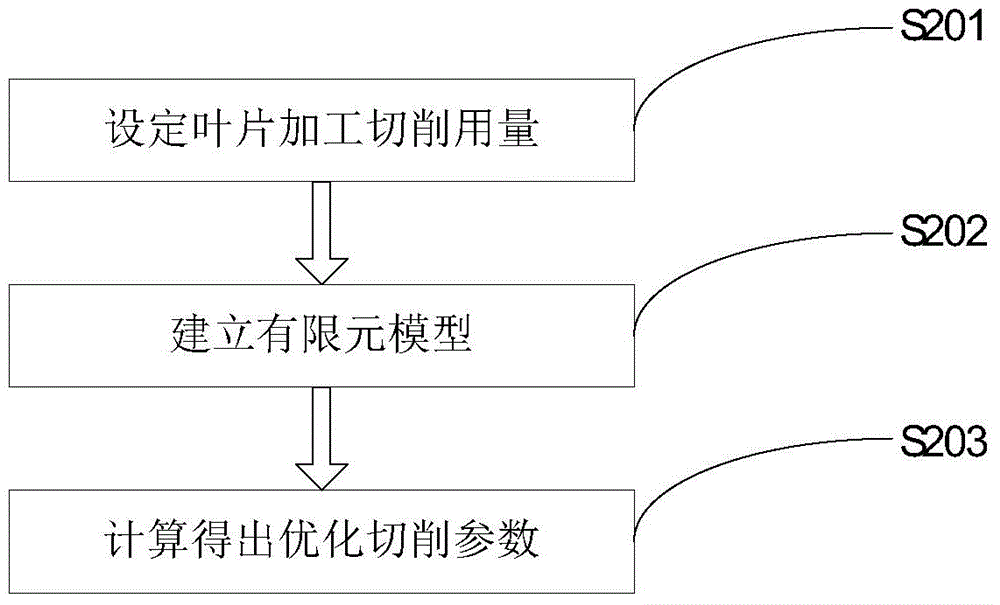

[0020] The establishment of the milling physical simulation model S101 refers to setting the initial cutting amount of the blade processing, compiling the verification optimization program, establishing the initial cutting parameters of the milling cutter position, and importing the finite element model after calculating the initial milling force to carry out the blade processing. Limited simulation analysis of milling processing. After the calculation is completed, according to the processing deformation data, the initial cutting amount is optimized and then recalculated in the imported model until the cutting force meets the tolerance requirements, and the optimized cutting parameters are calcul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com