Novel milling cutter

A milling cutter and a new type of technology, applied in milling cutters, milling machine equipment, manufacturing tools, etc., can solve the problems of shortened tool service life, easy chip sticking at the end of the cutter teeth, and high manufacturing cost, and can improve the processing speed and facilitate chip removal. Reliable, low-cost manufacturing results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below by means of the accompanying drawings and examples.

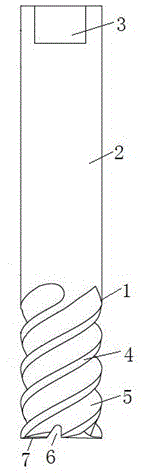

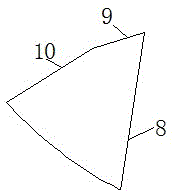

[0017] like figure 1 and figure 2 As shown, a novel milling cutter according to the present invention includes a cutter body 1, and a handle 2 connected to the cutter body 1, and an oil supply groove hole 3 is arranged on the upper part of the handle 2, and they are integrally formed. The cutter body 1 is composed of four sets of helical blades 4 and four sets of helical chip removal grooves 5, the helical blades 4 and the helical chip removal grooves 5 are evenly spaced, and the front parts of the two helical blades 4 on the same horizontal line are provided with Groove 6 is provided with chamfering teeth 7 at the other two helical blades 4 fronts, and described chamfering teeth 7 comprises first angle 8, is arranged on the second angle 9 besides first angle 8, and is arranged on the second The third angle 10 next to the angle 9, the first angle 8 is 10°, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com