Welding fixture for steel wire frameworks of back-row seat cushions of automobiles

A steel wire skeleton and welding fixture technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., to ensure accuracy, improve welding quality and production efficiency, and have wide applicability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] Below in conjunction with accompanying drawing and specific embodiment the present invention will be described in further detail:

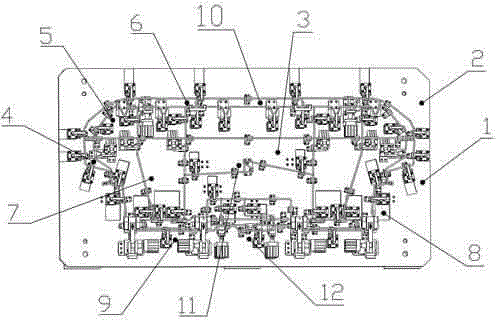

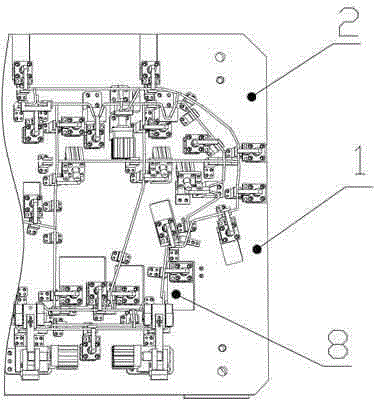

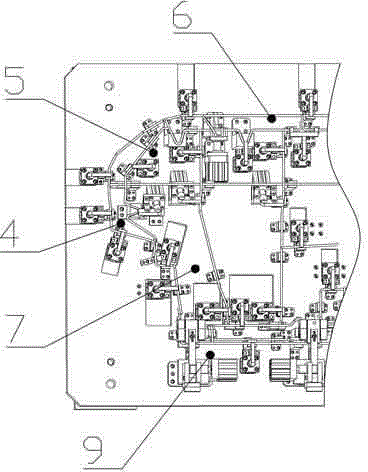

[0044] Such as Figure 1 ~ Figure 4 As shown, the welding fixture for the steel wire frame of the rear seat cushion of the automobile includes a base plate base 1, and the base plate base 1 is divided into three areas according to the seating area of the rear seat cushion, namely the left and right bases 2 arranged symmetrically. And the middle base 3 between the left and right bases; the left and right bases are symmetrically provided with the following devices: the first fixing device for fixing the radial outer edge and the inner edge steel wire on the left and right sides of the seat cushion 4. The second fixing device for fixing the outer edge and inner edge steel wire of the left and right arc parts on the left and right sides of the seat cushion 5. The third fixing device for fixing the outer edge and inner edge steel wire of the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com