Germanium tellurite glass for double-clad optical fiber and preparation method for optical fiber thereof

A tellurite glass and double-clad optical fiber technology, applied in glass manufacturing equipment, manufacturing tools, etc., can solve the problem of not covering germanium tellurate glass, and achieve the effect of saving raw materials and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] 1. The composition (mol) of the fiber core is: GeO 2 :60, TeO 2 :15, PbO:10, SrO:4, Al 2 o 3 :10,Nb 2 o 5 :1,Tm 2 o 3 :2;

[0036] 2. The composition (mol) of the inner cladding is: GeO 2 :60, TeO 2 :15, PbO:10, SrO:5, Al 2 o 3 :10;

[0037] 3. The composition (mol) of the outer cladding is: GeO 2 :65, TeO 2 :10, PbO:10, SrO:5, Al 2 o 3 :10;

[0038] 4. Mix the raw materials required for the core glass evenly, put them into a platinum crucible to melt and clarify at 1150°C, and stir the molten glass for 40 minutes. Then pour the molten glass into a preheated cylindrical metal mold, anneal in a tube furnace near the glass transition temperature for 6 hours, then turn off the power and cool down with the furnace to obtain a round rod-shaped core glass.

[0039] 5. The preparation methods of inner cladding glass, outer cladding glass and core glass are exactly the same.

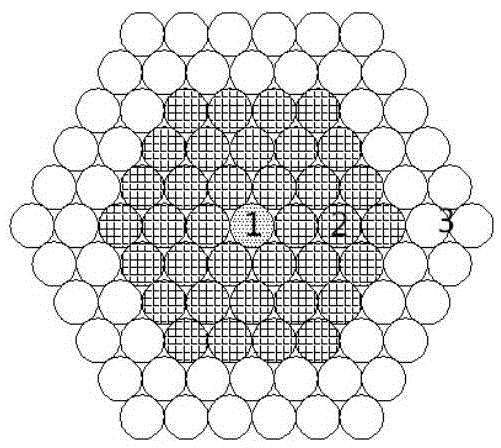

[0040] 6. Polish and clean the outer wall of the obtained round rod-shaped glass, an...

Embodiment 2

[0043] 1. The composition (mol%) of the fiber core is: GeO 2 :30, TeO 2 :55, PbO:10, CaO:3, Al 2 o 3 :1,Nb 2 o 5 :1,Tm 2 o 3 :0.5;

[0044] 2. The composition (mol%) of the inner cladding is: GeO 2 :30, TeO 2 :55, PbO:10, CaO:4, Al 2 o 3 :1;

[0045] 3. The composition (mol%) of the outer cladding is: GeO 2 :35, TeO 2 :50, PbO:10, CaO:4, Al 2 o 3 :1;

[0046] 4. Mix the raw materials required for the core glass evenly, put them into a platinum crucible to melt and clarify at 950°C, and stir the molten glass for 20 minutes. Then pour the molten glass into a preheated cylindrical metal mold, anneal in a tube furnace near the glass transition temperature for 6 hours, then turn off the power and cool down with the furnace to obtain a round rod-shaped core glass.

[0047] 5. The preparation methods of inner cladding glass, outer cladding glass and core glass are exactly the same.

[0048] 6. Polish and clean the outer wall of the obtained round rod-shaped glass, a...

Embodiment 3

[0051] 1. The composition (mol%) of the fiber core is: GeO 2 :38, TeO 2 : 17, PbO: 30, SrO: 10, Al 2 o 3 :2,Nb 2 o 5 :3,Tm 2 o 3 :1;

[0052] 2. The composition (mol%) of the inner cladding is: GeO 2 :42, TeO 2 :15, PbO:29, SrO:10, Al 2 o 3 :2,Nb 2 o 5 :2;

[0053] 3. The composition (mol%) of the outer cladding is: GeO 2 :47, TeO 2 :13, PbO:27, SrO:10, Al 2 o 3 :3;

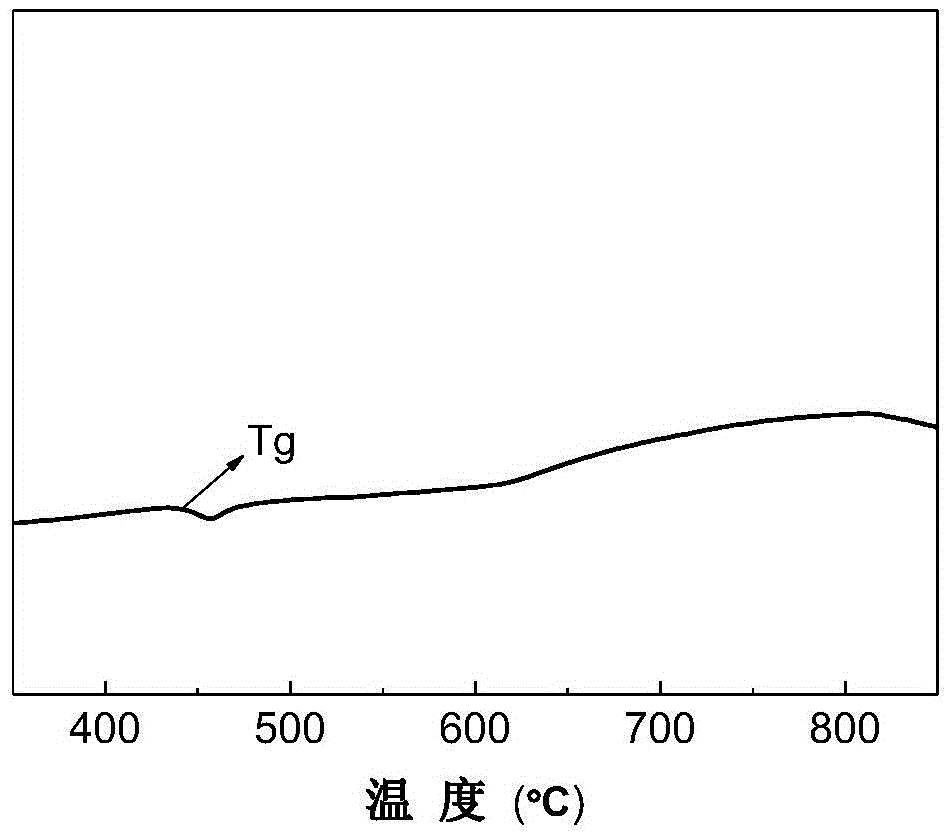

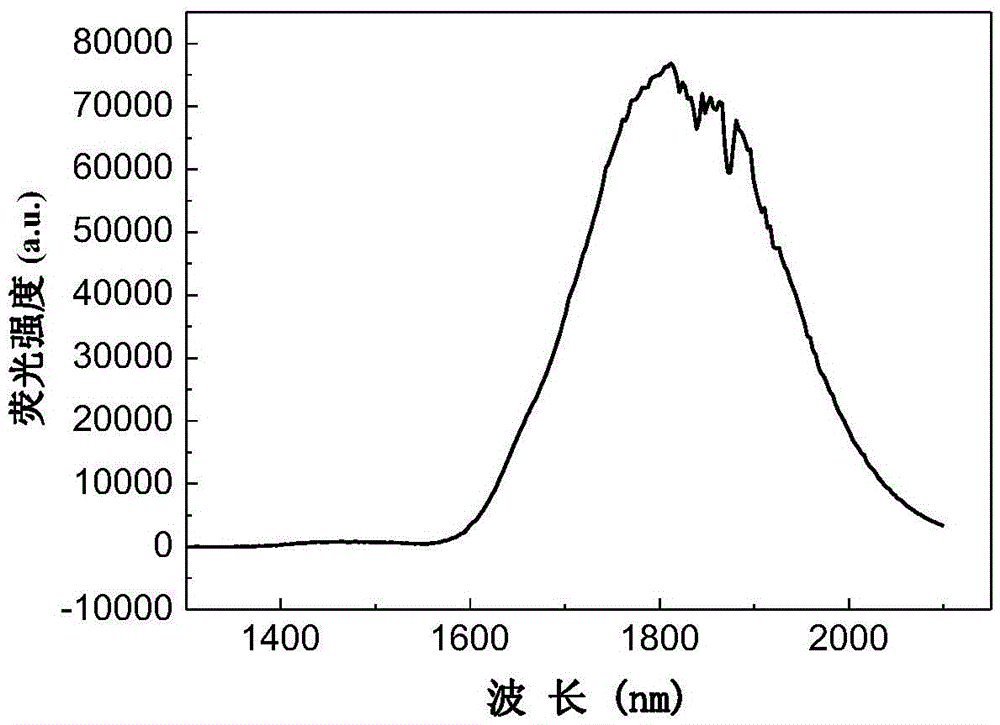

[0054] 4. Mix the raw materials required for the core glass evenly, put them into a platinum crucible to melt and clarify at 1050°C, and stir the molten glass for 25 minutes. Then pour the molten glass into a preheated cylindrical metal mold, anneal in a tube furnace near the glass transition temperature for 6 hours, then turn off the power and cool down with the furnace to obtain a round rod-shaped core glass. Conduct thermal property test and spectrum test on the core glass, the results are as follows figure 2 and image 3 shown.

[0055] 5. The preparation method of the inner cladding gl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com