Production method of raw material for antifreezing antibacterial glass fiber high performance composite pipe and the composite pipe

A manufacturing method and technology of composite pipes, applied to rigid pipes, chemical instruments and methods, pipes/pipe joints/pipe fittings, etc., can solve the problems of troublesome production, cracking of pipes, and troublesome proportioning process, so as to achieve fewer processes and reduce The effect of simple manufacturing cost and ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

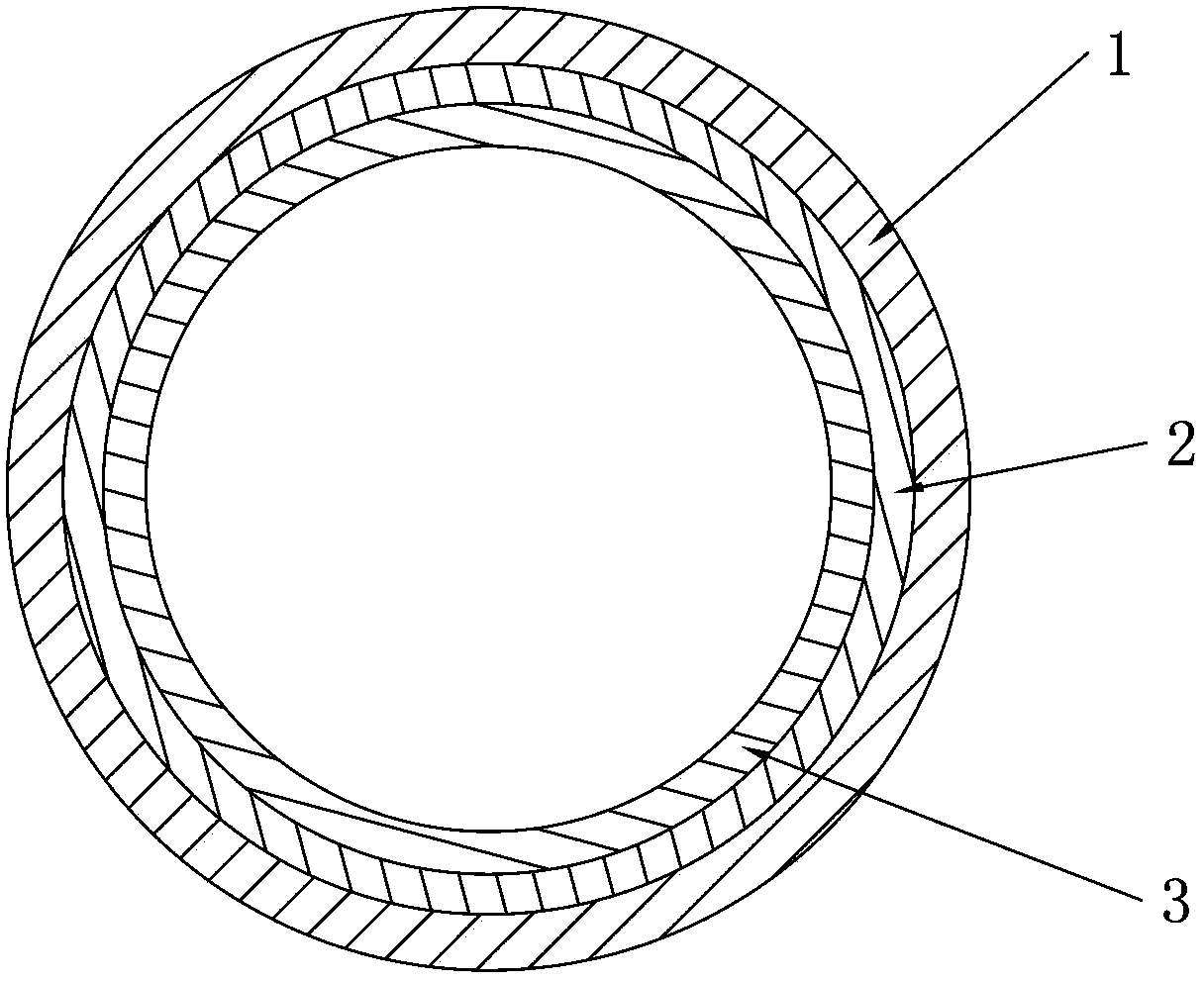

Image

Examples

Embodiment approach 1

[0039] Embodiment 1: The method for manufacturing the antifreeze and antibacterial glass fiber high-performance composite pipe raw materials of the present invention, wherein:

[0040] 1) Production of antifreeze plastic raw materials: add 10% (weight percent) of antifreeze plastic masterbatch to 90% (weight percent) carrier resin A, stir evenly for 3 minutes, and obtain antifreeze plastic raw materials after impregnation;

[0041] 2) Production of antibacterial plastic raw materials: adding 5% (weight percent) of antibacterial plastic masterbatch to 95% (weight percent) carrier resin B, stirring evenly for 10 minutes, and obtaining antibacterial plastic raw materials after impregnation;

[0042] 3) Production of glass fiber plastic raw materials: Add 55% (weight percentage) of glass fiber plastic masterbatch to 45% (weight percentage) of carrier resin C, stir evenly for 10 minutes, and obtain glass fiber plastic raw materials after impregnation.

[0043] The above-mentioned a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com