Composite material for making midsole plate of shoes and preparation method thereof

A composite material and base plate technology, applied in the field of composite materials and its preparation, can solve problems such as singleness, troublesome manufacturing, and poor anti-puncture effect, and achieve high wear resistance, convenient processing, and good anti-puncture effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

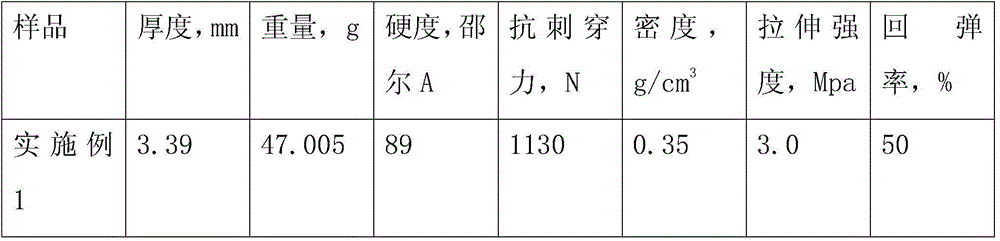

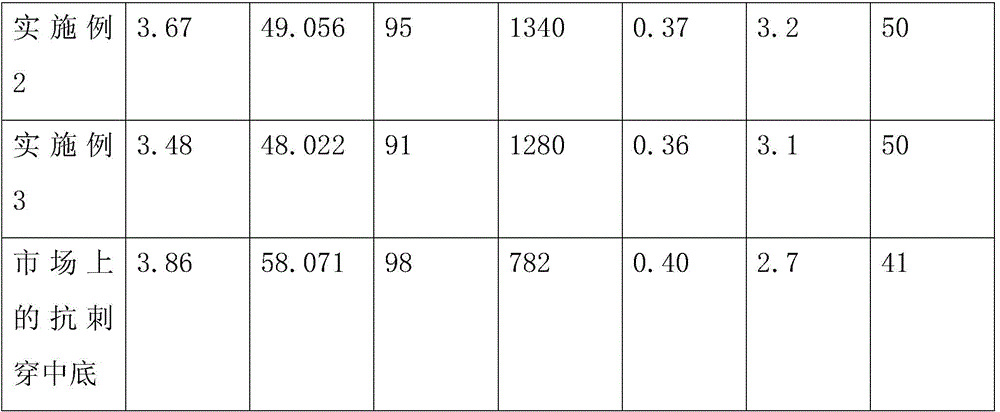

Embodiment 1

[0027] (1) configuration raw material, described raw material comprises by weight parts:

[0028] 60 parts of aramid fiber, 2 parts of polyethylene, 0.5 parts of crosslinking agent, 80 parts of styrene-butadiene block copolymer, 10 parts of polystyrene, 5 parts of butadiene rubber, 5 parts of naphthenic oil, azo Diformamide 0.5 part, Zinc Stearate 0.5 part, Zinc Oxide 0.5 part, Nano Y 2 o 3 10 parts of ceramic powder; wherein, the fiber length of aramid fiber is 1mm;

[0029] (2) Add formula raw material fiber, polyethylene, crosslinking agent, styrene-butadiene block copolymer, polystyrene, butadiene rubber, naphthenic oil, azodicarbonamide, zinc stearate in sequence , zinc oxide, after stirring at high speed for 5-7 minutes, move it into the internal mixer; add Y 2 o 3 Nano-ceramic powder, banburying for 15 minutes, discharged at a temperature of 90-100°C; at a temperature of 150°C, molded and inspected by a film forming machine, it is a finished product.

Embodiment 2

[0031] (1) configuration raw material, described raw material comprises by weight parts:

[0032] 100 parts of glass fiber, 14 parts of polyethylene, 3 parts of crosslinking agent, 100 parts of styrene-butadiene block copolymer, 40 parts of polystyrene, 20 parts of butadiene rubber, 30 parts of naphthenic oil, azobis 3 parts of formamide, 2 parts of zinc stearate, 2 parts of zinc oxide, nano Y 2 o 3 15 parts of ceramic powder; Wherein, the fiber length of glass fiber is 2mm;

[0033] (2) Add formula raw material fiber, polyethylene, crosslinking agent, styrene-butadiene block copolymer, polystyrene, butadiene rubber, naphthenic oil, azodicarbonamide, zinc stearate in sequence , zinc oxide, after stirring at high speed for 5-7 minutes, move it into the internal mixer; add Y 2 o 3 Nano-ceramic powder, banburying for 30 minutes, discharged at a temperature of 90-100°C; at a temperature of 150°C, molded and inspected by a film forming machine, it is a finished product.

Embodiment 3

[0035] (1) configuration raw material, described raw material comprises by weight parts:

[0036] 80 parts of aramid fiber, 10 parts of polyethylene, 3 parts of crosslinking agent, 80 parts of styrene-butadiene block copolymer, 40 parts of polystyrene, 20 parts of butadiene rubber, 30 parts of naphthenic oil, azo 3 parts of dimethylamide, 0.5 parts of zinc stearate, ~2 parts of zinc oxide, 50 parts of glass fiber, ZrO 2 15 parts of ceramic powder; wherein, the length unit of aramid fiber fiber is mm;

[0037] (2) Add formula raw material fiber, polyethylene, crosslinking agent, styrene-butadiene block copolymer, polystyrene, butadiene rubber, naphthenic oil, azodicarbonamide, zinc stearate in sequence , zinc oxide, after stirring for 5 to 7 minutes at high speed, move it into the internal mixer; add ZrO 2 Nano-ceramic powder, banburying for 20 minutes, discharged at a temperature of 90-100°C; at a temperature of 150°C, molded and inspected by a film forming machine, it is a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com