One-step forming construction method for expressway high-modulus asphalt composite

A technology of asphalt mixture and expressway, which is applied in the direction of roads, roads, road repairs, etc. It can solve the problems of difficult compaction of asphalt mixture, failure to meet specification requirements, base temperature loss, etc., and achieve good construction quality and good economic benefits and social benefits, reducing the effect of bonding course construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

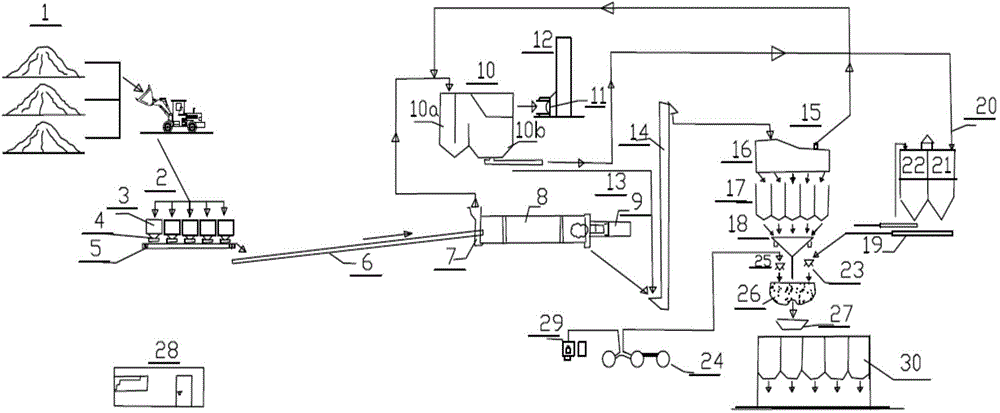

[0023] The one-shot construction method of high modulus asphalt mixture for expressways includes the process steps of high modulus asphalt mixture design, mixing, transportation, paving, rolling, joint treatment and maintenance. Implement the required materials, equipment and personnel of the steps of the present invention to form as follows:

[0024] 1.1 Material preparation

[0025] Tested aggregate and 20 / 30 asphalt.

[0026] 1.2 Device configuration

[0027] 1.2.1 Mixing equipment

[0028] Xizhu J4000 batch asphalt mixing plant.

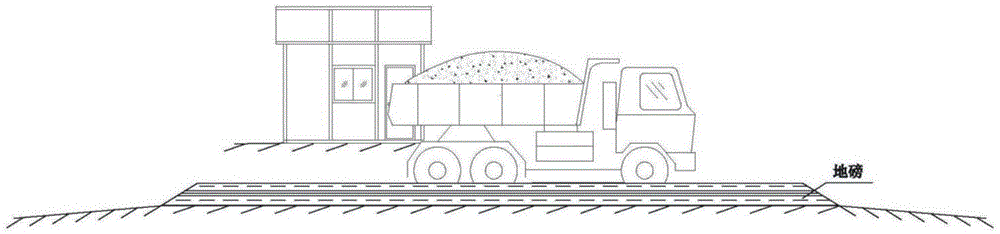

[0029] 1.2.2 Transportation equipment

[0030] Several large-tonnage dump trucks.

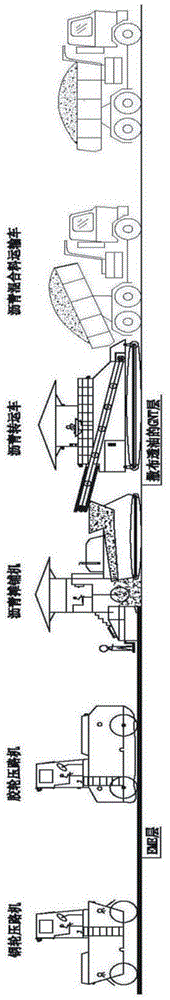

[0031] 1.2.3 Paving equipment

[0032] Dynapac F141C paver and asphalt transfer vehicle equipped with automatic leveling device.

[0033] 1.2.4 Rolling equipment

[0034] Two YL26C tire rollers (with a dead weight of 26 tons) and three YZC12C double-drum rollers.

[0035] 1.2.5 Other equipment

[0036] Loaders, air compressors, cutting machines, generato...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com