Tension construction method of steel strand cable with anti-skid key as locking device

A technology of locking device and construction method, which is applied in the direction of cable-stayed bridges, erection/assembly bridges, bridge forms, etc., and can solve problems such as pulling fatigue effect, bending fatigue, and insufficient grouting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

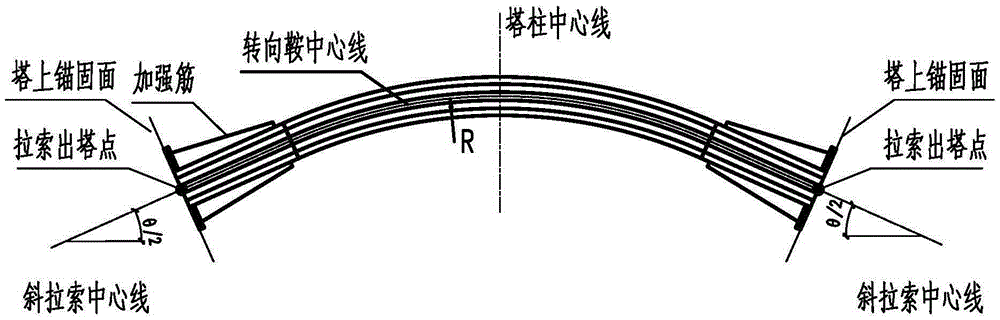

[0061] Such as Figure 9 and Figure 10 As shown, a kind of tensioning construction method of the steel strand cable using the anti-slip key as the locking device in this embodiment, the steel strand cable with the anti-slip key as the locking device is threaded on the tower column, and each An anti-skid key is arranged on each steel strand, and the anti-skid key is arranged staggeredly on both sides of the tower column, including the following steps:

[0062] Step 1: A unilateral hypertension force is applied to the steel strand cables that are not provided with anti-skid keys on the side near the tower column.

[0063] Step 2: The steel strand cables on one side of the tower column are respectively over-tensioned by half of the number of steel strands during the construction stage.

[0064] Step 3, each bundle of steel strand cables should start from the steel strand located in the middle when tensioned, and then go outward one by one.

[0065] Step 4. Record the target t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com