Steel and concrete combined connecting piece with changeable dual column caps

A technology for connecting parts and concrete, applied in bridge parts, bridges, buildings, etc., can solve the problems of high rigidity, disadvantage, and large support pressure of welding studs, and achieve the effects of replacement, convenient construction and uniform shear force distribution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

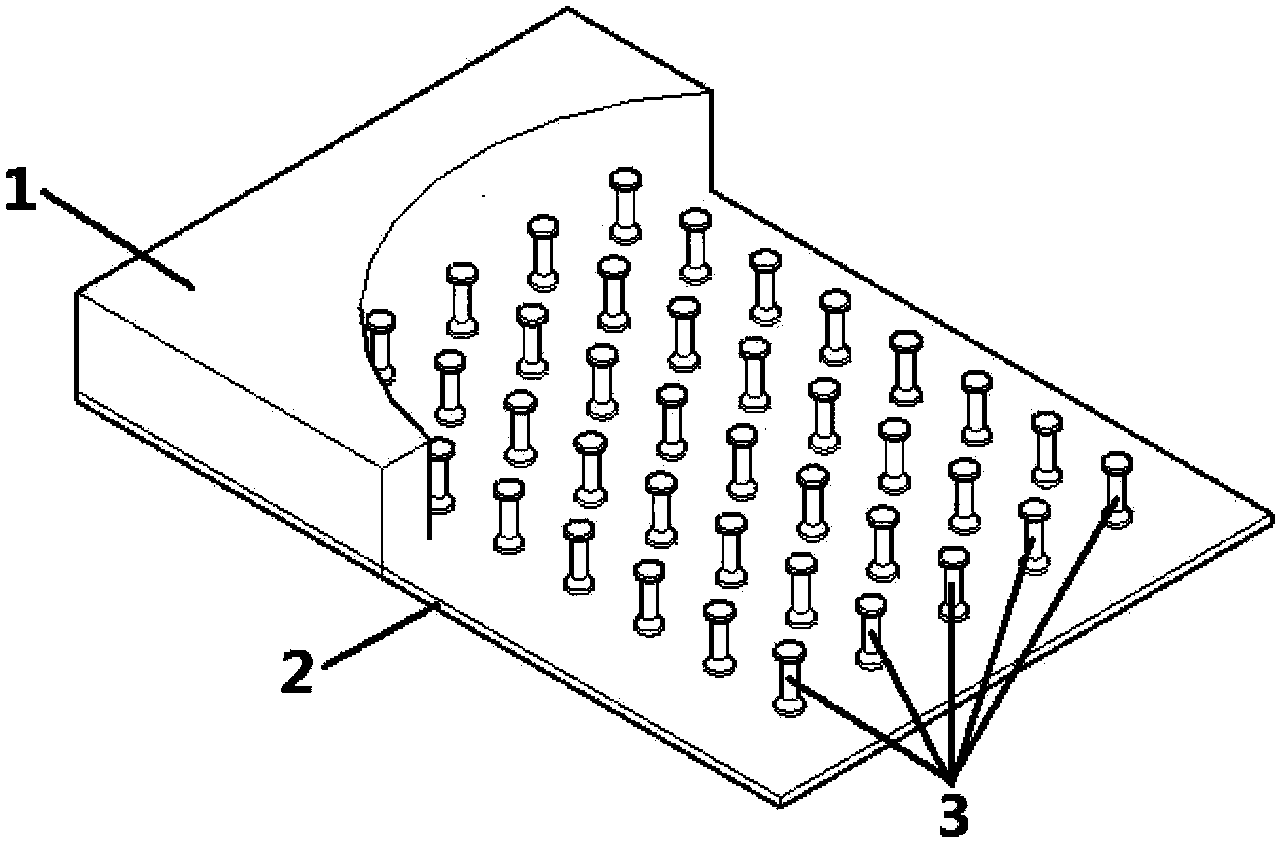

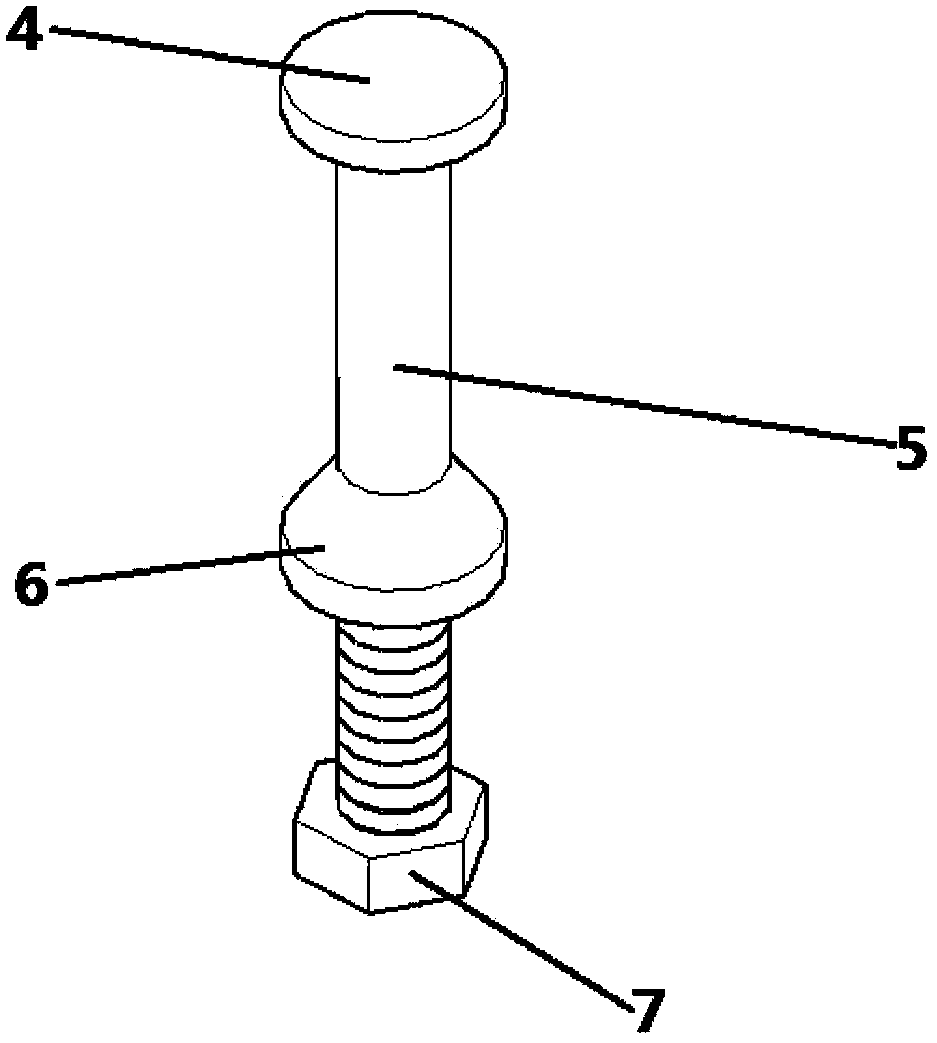

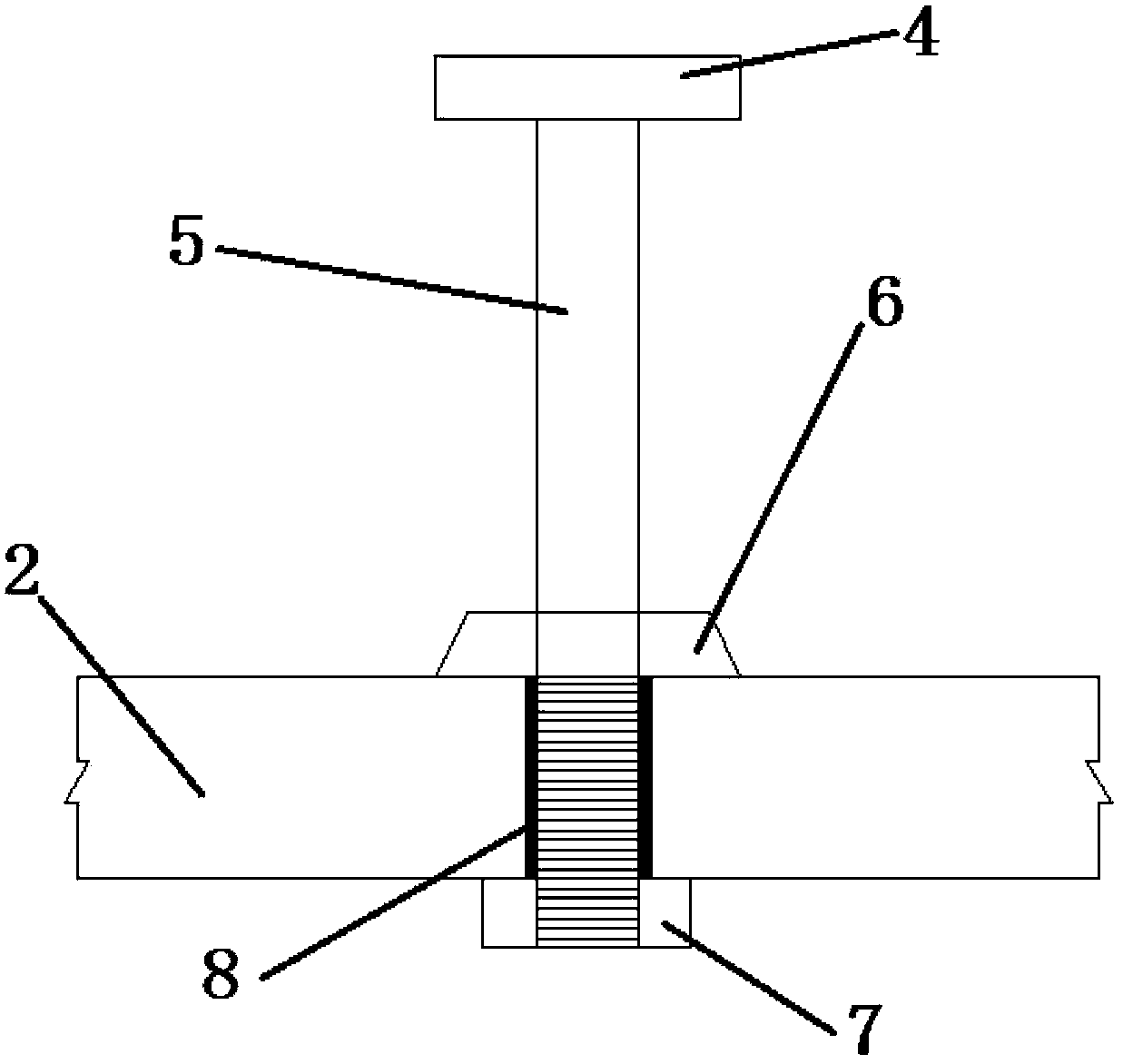

[0020] like figure 1 and figure 2 As shown, a replaceable connecting piece with double column heads combined steel and concrete, the connecting piece 3 is penetrated in the installation hole of the steel mother plate 2, and serves as a shear force connecting piece on the joint surface of the steel mother plate 2 and the concrete 1 . The connecting piece includes a rod body 5 and a nut 7 , the upper end of the rod body 5 is provided with an end welding nail cap 4 , and the middle part of the rod body 5 is provided with a middle column head 6 . The connection structure between the connector and the steel plate is as follows: image 3 As shown, the part above the middle stigma 6 on the rod body is smooth, and the part below the middle stigma 6 is pierced in the installation hole of the steel mother plate 2, and is provided with threads. 6 Cooperate up and down to clamp the rod body 5 of the connector 3 on the steel mother plate 2.

[0021] The invention discloses a replaceabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com