Bimetallic material friction welding air valve detection device

A testing device and friction welding technology, applied in the direction of measuring device, testing of mechanical parts, testing of machine/structural parts, etc., can solve the quality inspection goals that cannot reflect the quality requirements of weld strength and cannot achieve 100% inspection , can not truly reflect the subtle defects of the weld, etc., to achieve the effect of efficient post-weld inspection, reliable non-destructive testing, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

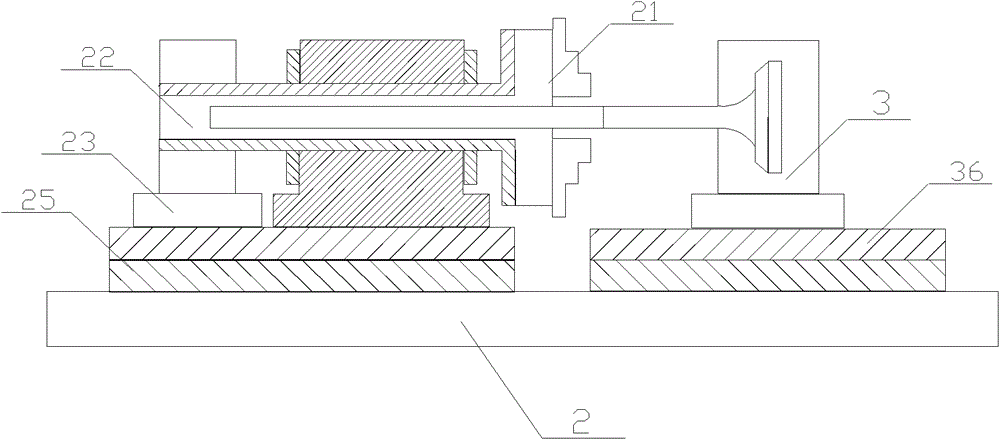

[0019] The model of pressure sensor DYZ-101 and displacement sensor used in the following examples is GBC-Q-200.

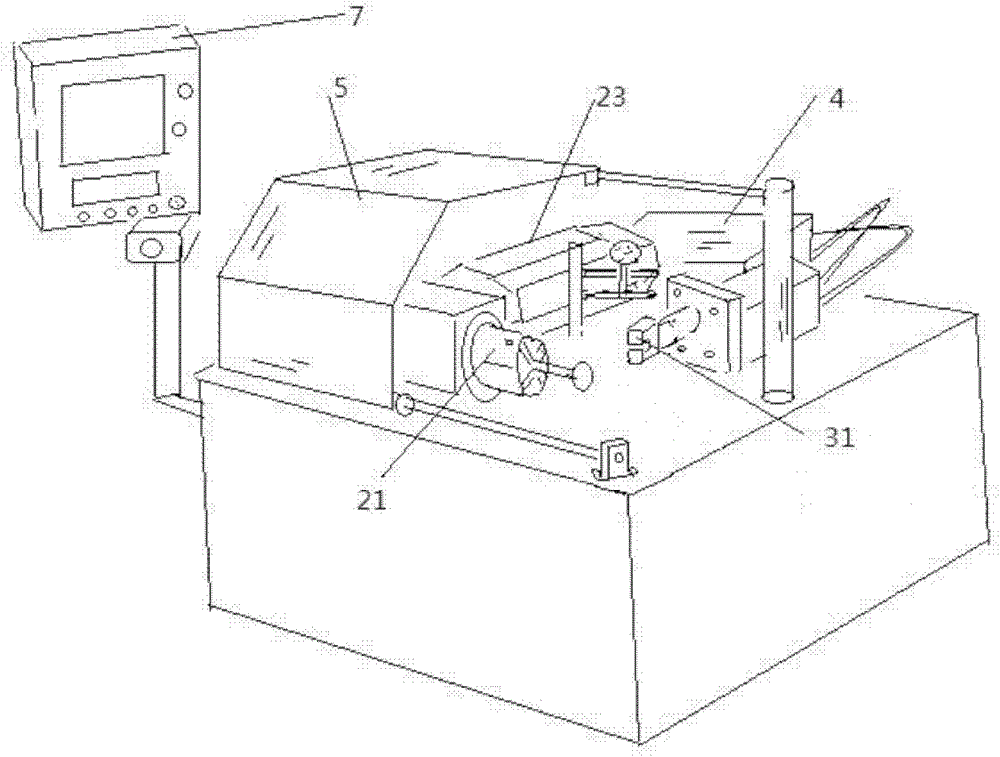

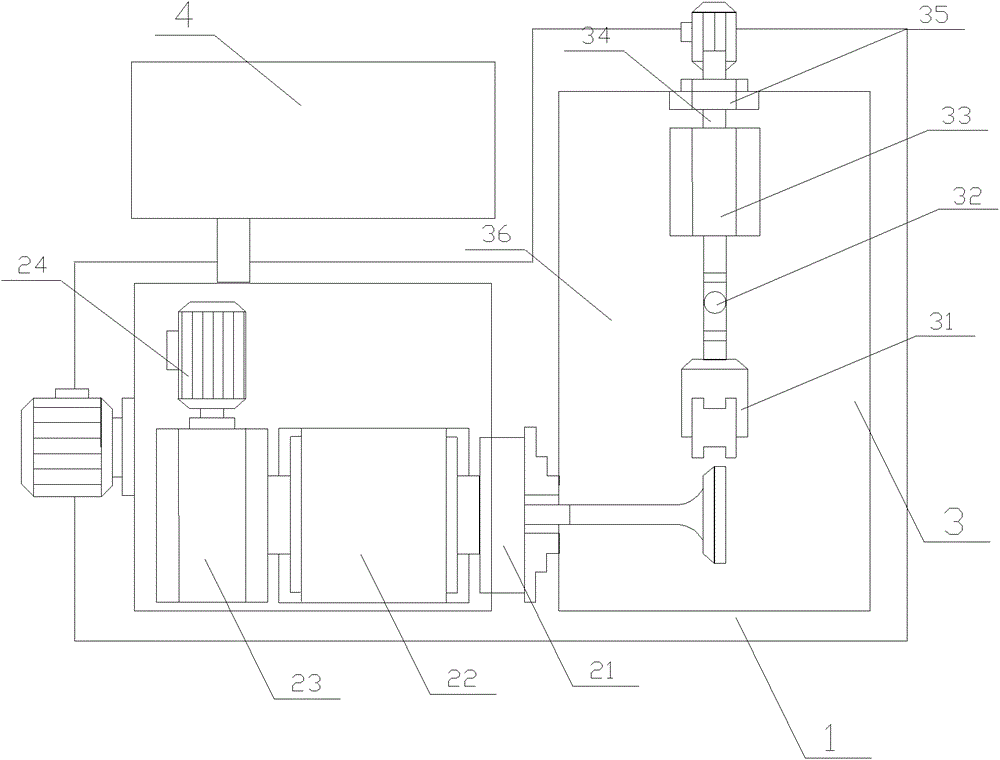

[0020] This embodiment provides a bimetal material friction welding gas valve detection device, the structure is as follows Figure 1 to Figure 4 As shown, it includes a base 1, a rotary feed mechanism 2, a pressing mechanism 3 and a hydraulic mechanism 4; in this embodiment, an L-shaped split base is used, and a hydraulic pressure is provided at the L-shaped groove on the side of the base. Mechanism, the hydraulic mechanism is connected with the pressing mechanism through the hydraulic oil pipe.

[0021] The rotary feed mechanism includes a first mechanical slide 25 installed on the base, a main shaft 22 is arranged on the mechanical slide, one end of the main shaft is connected with the output shaft of the speed reducer 23, and the other end is connected with the clamp of the three-jaw chuck 21. The disc body is locked in phase, and a three-phase motor 24...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com