Magnetic motor

A motor and magnetic energy technology, applied in the field of engines, can solve the problems of not using permanent magnet materials 100%

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

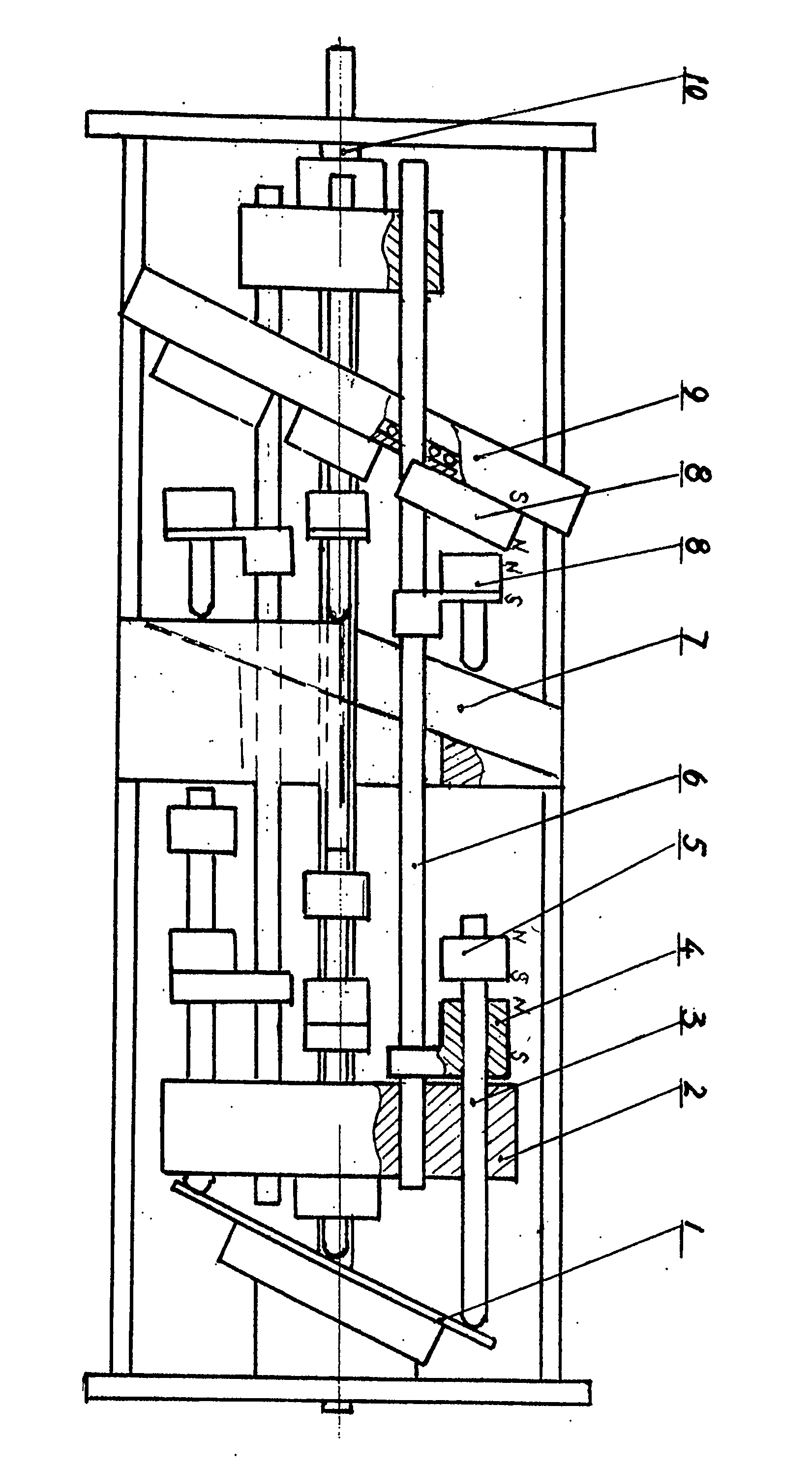

[0012] exist figure 1 , the spool magnet (5) is attracted to the magnetic ring (4) sleeved in the middle of the spool (3). Sliding column (3) produces thrust to swash plate a (1). Since the swash plate a(1) has an inclination angle, the thrust is divided into two parts. One of the parts is perpendicular to the spool (3) to generate a torque on the axis of the rotor (2), driving the rotor (2) to rotate.

[0013] The magnetic ring (4) is connected with another pair of balance magnets (8) by a connecting rod (6). The forces produced by the two magnetic fields are in balance (same magnitude but opposite directions). Make the magnetic ring (4) move extremely easily.

[0014] The power distribution plate (7) synchronously and regularly adjusts the distance between the magnetic ring (4) and the sliding column magnet (5) and the distance between a pair of balance magnets (8) through the connecting rod (6). Configure magnetism.

[0015] It should be reminded here that the force b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com