A kind of anti-permeation gas pottery basin and preparation method

A technology of air-permeable pottery and pottery pots, which is applied in botany equipment and methods, container cultivation, gardening, etc. It can solve the problems of poor air permeability and easy water leakage, and achieve the effects of not easy to fall off, high connection strength, and avoiding capillary force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0071] A commercially available common pottery pot is used, which is made of aluminum oxide and silicon oxide as main raw materials, and also contains a small amount of magnesium oxide. The average pore diameter is 0.2 μm, and the porosity is 30%.

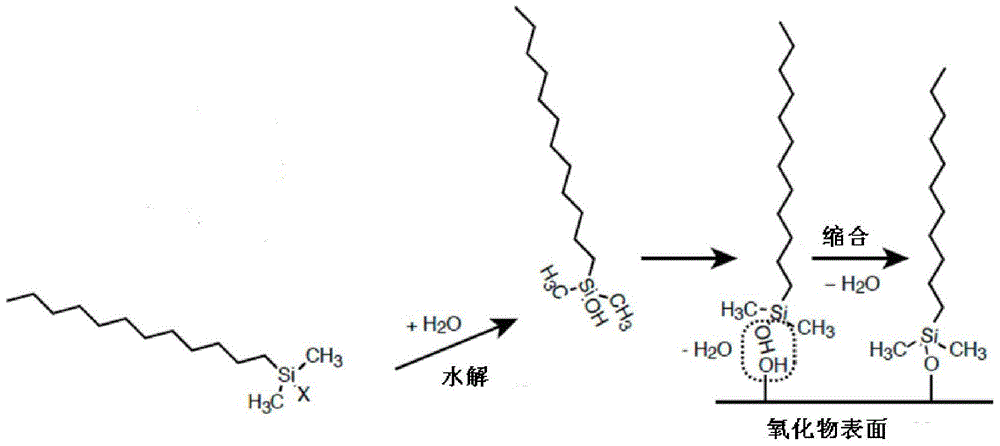

[0072] First, put the ordinary pottery pot in water to clean it, then take it out and dry it at 110°C; use ethanol as solvent, trimethylchlorosilane ((CH3) 3Si-Cl) is formulated into the mixture that the volume molar concentration range of organosilane is 10mmol / L;

[0073] Next, soak the dried clay pot in the above-mentioned ethanol solution of trimethylchlorosilane, and place it at room temperature for 2 hours;

[0074] Take it out and dry it at 120°C for 2 hours. A pottery basin with anti-permeation gas particles on the inner and outer surfaces is obtained.

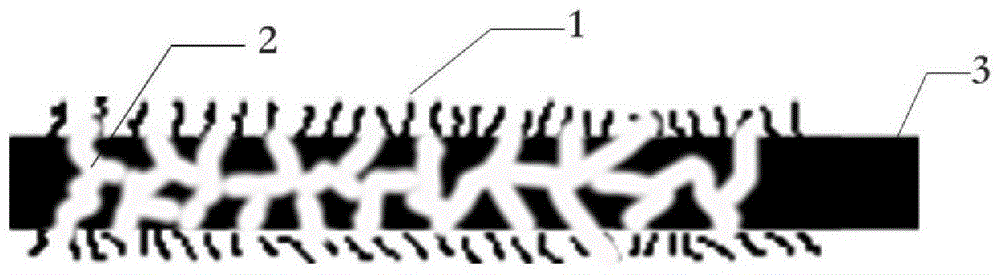

[0075] In this embodiment, the ethanol solution of trimethylchlorosilane can also be directly poured into a pot for soaking. The schematic diagram of the structure of t...

Embodiment 2

[0080] A commercially available common pottery pot is used, which is made of alumina and silicon oxide as main raw materials, and also contains a small amount of iron oxide. The average pore size is 1 μm and the porosity is 40%.

[0081] First, put the ordinary pottery pot in water to clean it, then take it out and dry it at 110°C; use ethanol as solvent, dimethylhexadecylchlorosilane ((CH3) 2 C 16 h 33 Si-Cl) is formulated into the mixture that the volume molar concentration range of organosilane is 30mmol / L;

[0082] Next, soak the dried clay pot in the above-mentioned ethanol solution of dimethylhexadecylchlorosilane, and place it at room temperature for 2 h;

[0083] Take it out and dry it at 120°C for 2 hours. A pottery basin with anti-permeation gas particles on the inner and outer surfaces is obtained.

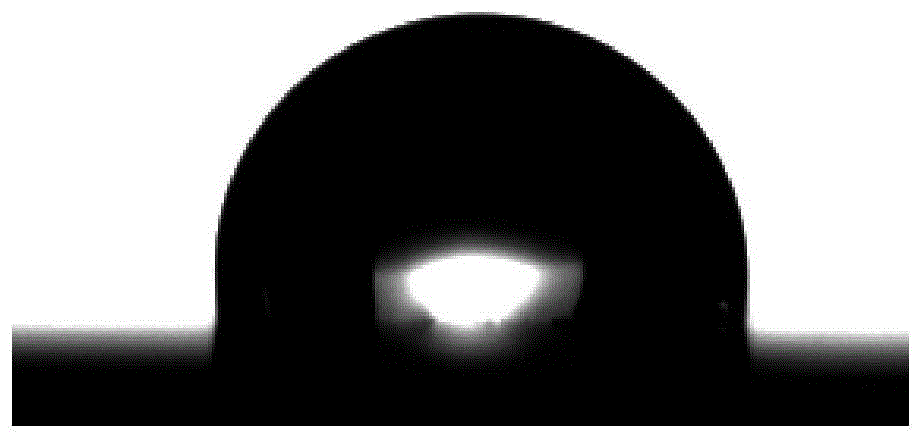

[0084] Carry out the contact degree test on the prepared pottery basin, such as Figure 3b shown. The contact angle photos of ordinary pottery basins are as foll...

Embodiment 3

[0088] A commercially available common pottery pot is used, which is made of alumina and silicon oxide as main raw materials, and also contains a small amount of iron oxide. The average pore diameter is 10 μm, and the porosity is 50%.

[0089] First, put the ordinary pottery pot in water to clean it, then take it out and dry it at 110°C; use ethanol as solvent, and organic silane (C 3 h 7 ) 2 (C 2 h 4 CH=CH 2 ) Si-OCH 3 The volume molar concentration scope that makes organic silane is the mixture of 50mmol / L;

[0090] Next, soak the dried clay pot in the above-mentioned ethanol solution of organosilane, and place it at room temperature for 2 h;

[0091] Take it out and dry it at 120°C for 2 hours. A pottery basin with anti-permeation gas particles on the inner and outer surfaces is obtained.

[0092] The air permeability test was carried out, and after 20 hours of treatment, the oxygen content of the water in the anti-permeation gas pottery basin was 7.80 mg / L.

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com