Slow-release hydrophobic agent for cement-based materials, hydrophobic cement and preparation method thereof

A technology of cement-based material and hydrophobic agent, applied in the field of slow-release hydrophobic agent, can solve the problems of high cost and complicated operation, and achieve the effect of improving compactness, less dosage and low economic cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

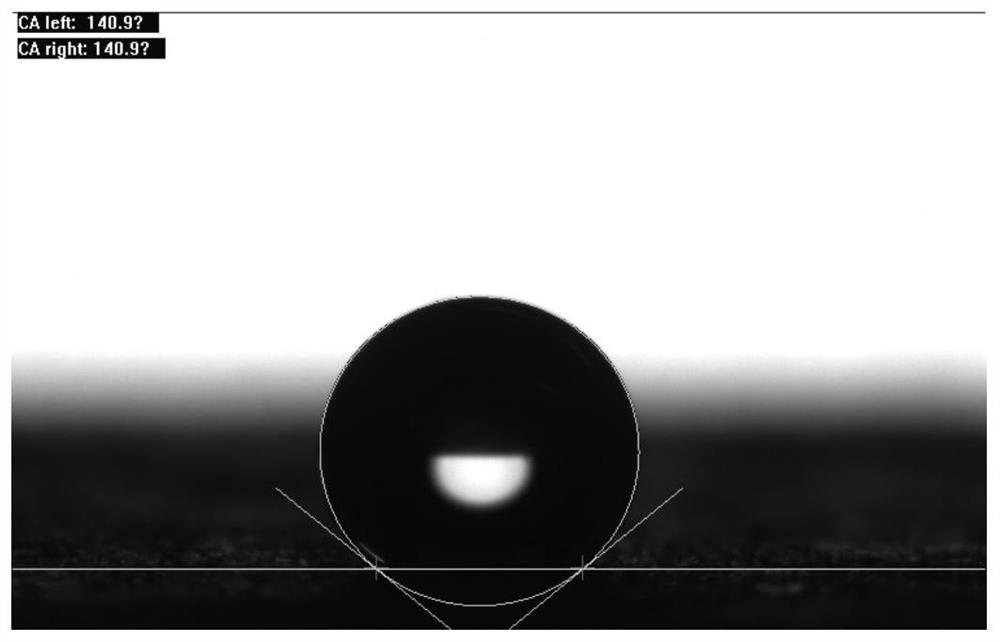

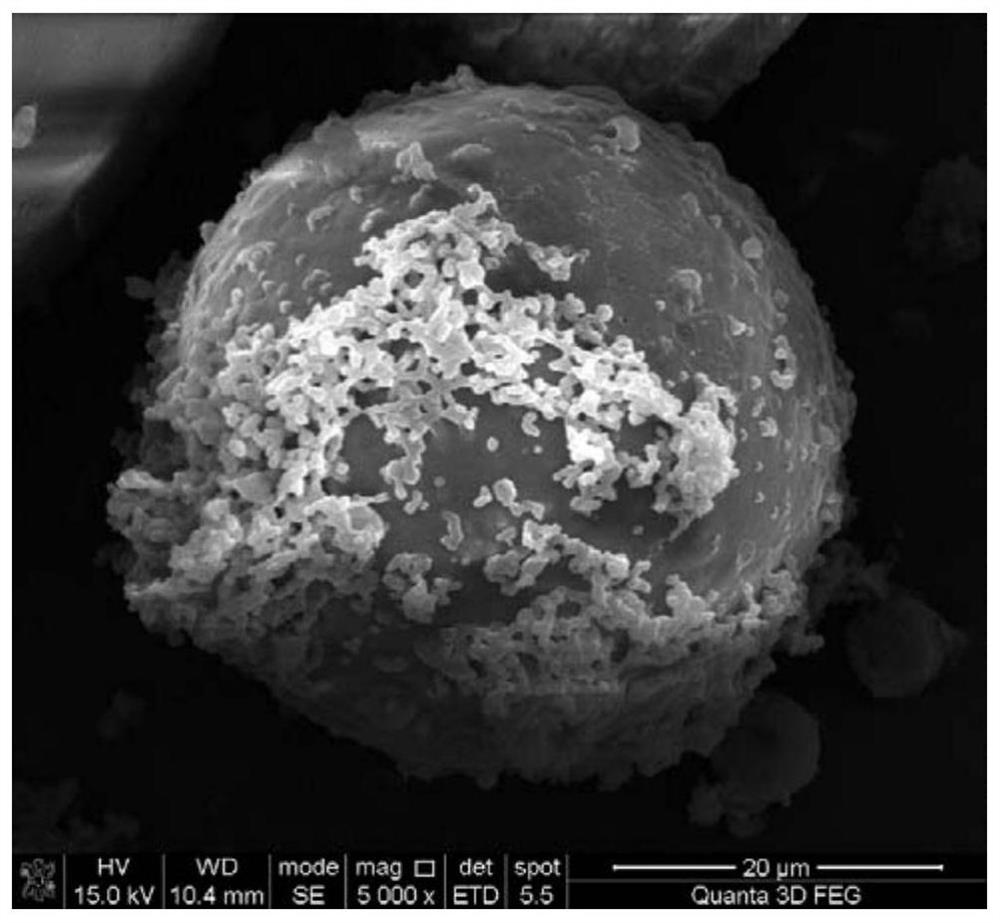

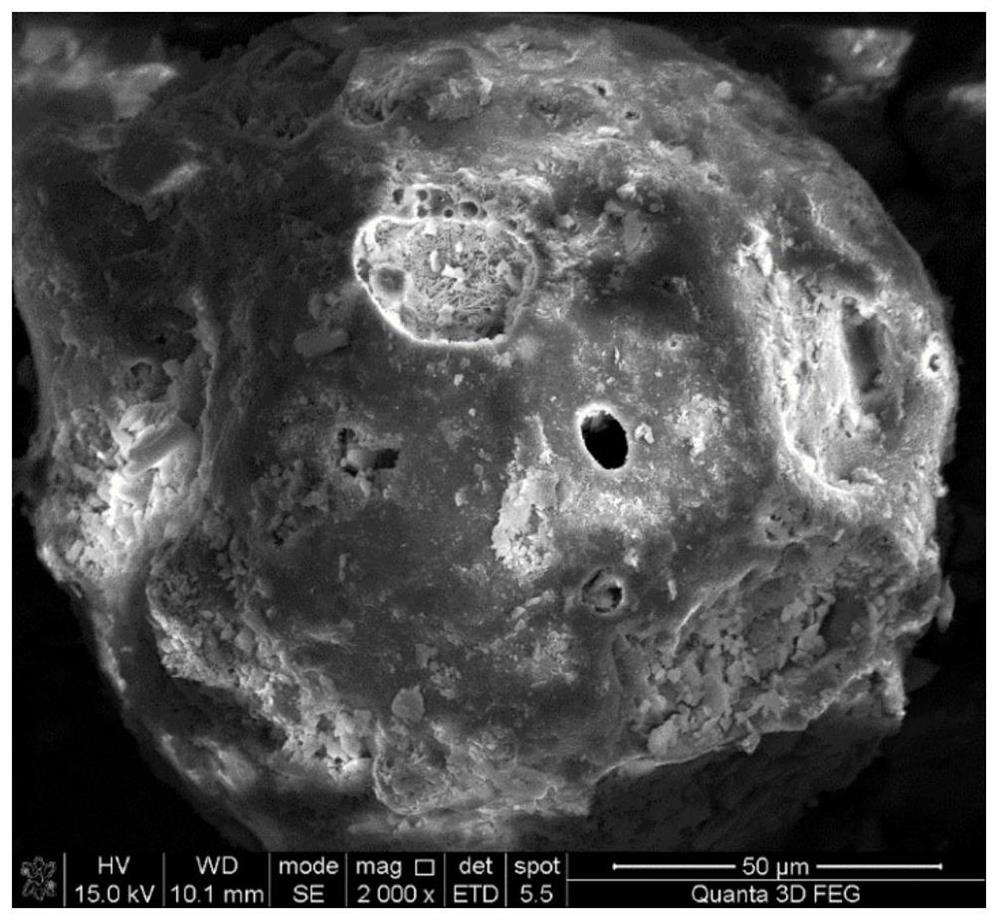

[0028] Add 1 part of fluorosilane and 1 part of alkyl siloxane to 100 parts of absolute ethanol to obtain the soaking solution of floating beads. Mix 2 parts of ammonium fluoride and 65 parts of dilute hydrochloric acid to prepare an acid etching solution for etching floating beads. Add 3 parts of floating beads to the mixed solution and soak for 6 hours; Soak in water for 1d; filter and dry the floating beads in clear water at 60°C, put the floating beads in the soaking solution, soak in a vacuum of 80Kpa for 1d, and then place the floating beads in 6 parts of silica sol for soaking after suction filtration After 4 hours, dry in a drying oven at 60°C for 1 day to obtain modified floating beads.

[0029] The above-mentioned modified floating beads are used as raw materials to prepare hydrophobic cement doped with 5% and 10% slow-release hydrophobic agents. The preparation process is as follows:

[0030] Weigh 20 parts of cement and 30 parts of fine sand, add modified floating...

Embodiment 2

[0032]Add 1 part of fluorosilane and 1 part of alkyl siloxane to 50 parts of absolute ethanol to obtain the soaking solution of floating beads. Mix 2 parts of ammonium fluoride and 65 parts of dilute hydrochloric acid to prepare an acid etching solution for etching floating beads. Add 3 parts of floating beads to the mixed solution and soak for 10 hours; Soak in water for 1d; filter and dry the floating beads in clear water at 70°C, put the floating beads in the soaking solution, soak in a vacuum of 100Kpa for 1d, and then place the floating beads in 10 parts of silica sol for soaking after suction filtration 6h, dry in a drying oven at 70°C for 1d to obtain modified floating beads.

[0033] The above-mentioned modified floating beads are used as raw materials to prepare hydrophobic cement doped with 15% slow-release hydrophobic agent. The preparation process is as follows:

[0034] Weigh 20 parts of cement and 30 parts of fine sand, and add modified floating beads with a mas...

Embodiment 3

[0036] Add 1 part of fluorosilane and 1 part of alkyl siloxane into 80 parts of absolute ethanol to obtain the soaking solution of floating beads. Mix 2 parts of ammonium fluoride and 65 parts of dilute hydrochloric acid to prepare an acid etching solution for etching floating beads. Add 3 parts of floating beads to the mixed solution and soak for 8 hours; Soak in water for 1d; filter and dry the floating beads in clear water at 60°C, put the floating beads in the soaking solution, soak in a vacuum of 60Kpa for 2d, and then place the floating beads in 8 parts of silica sol for 5 hours after suction filtration , dried in a drying oven at 60°C for 1 day to obtain modified floating beads.

[0037] The above-mentioned modified floating beads are used as raw materials to prepare hydrophobic cement doped with 15% slow-release hydrophobic agent. The preparation process is as follows:

[0038] Weigh 20 parts of cement and 30 parts of fine sand, and add modified floating beads with a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com