A kind of expansion material with slow reaction rate and preparation method thereof

An intumescent material and functional technology, applied in the field of intumescent materials and their preparation, can solve problems such as insufficient expansion performance, and achieve the effects of improving hydration, slowing down the acceleration effect, and reducing the amount of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

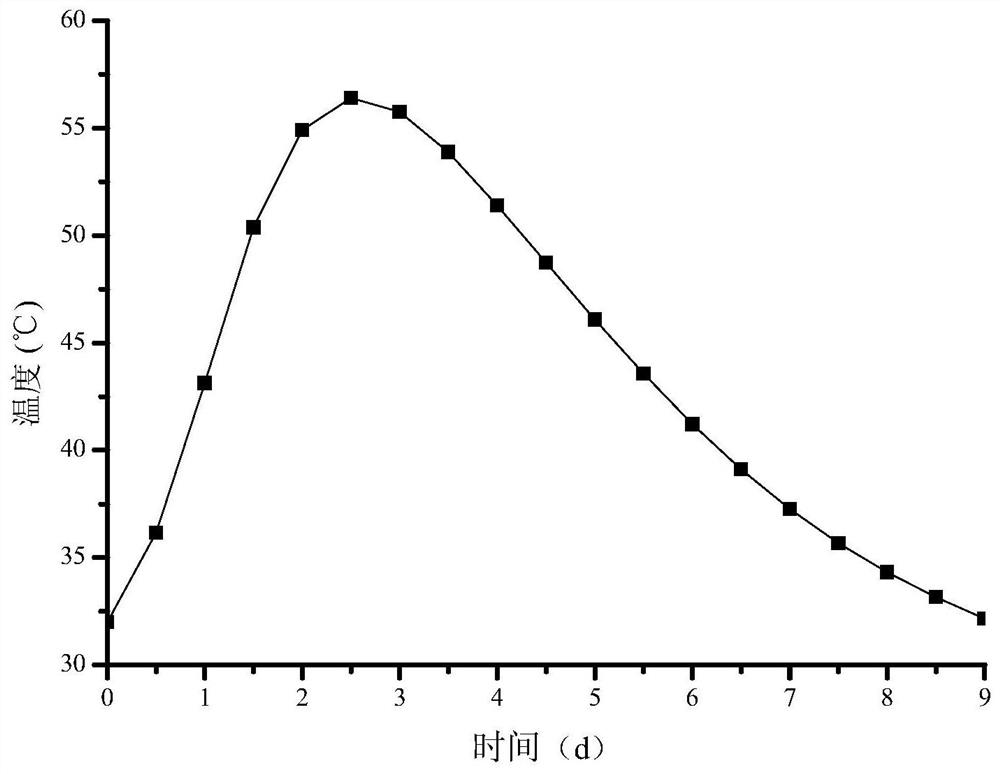

Image

Examples

Embodiment 1

[0040] 100 parts of boric acid, 400 parts of pregelatinized starch, and 1100 parts of water were added to form a homogeneous solution, and spray-dried to obtain a control admixture with slow and controlled release function.

Embodiment 2

[0042] 100 parts of dextrin, 150 parts of pre-gelatinized starch, and 700 parts of water were added to form a homogeneous solution, and spray-dried to obtain a control admixture with slow and controlled release function.

Embodiment 3

[0044] 100 parts of borax, 400 parts of pre-gelatinized starch, and 580 parts of water were added to form a homogeneous solution, and spray-dried to obtain a control admixture with slow and controlled release function.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com