Method for preparing high-purity acrylonitrile

An acrylonitrile, high-purity technology, applied in the preparation of hydrocarbon ammoxidation, purification/separation of carboxylic acid nitrile, organic chemistry, etc., can solve the problems of inability to react, decrease of hydratase activity, shortening of reaction batches, etc., and achieve the solution of low temperature The effect of poor solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

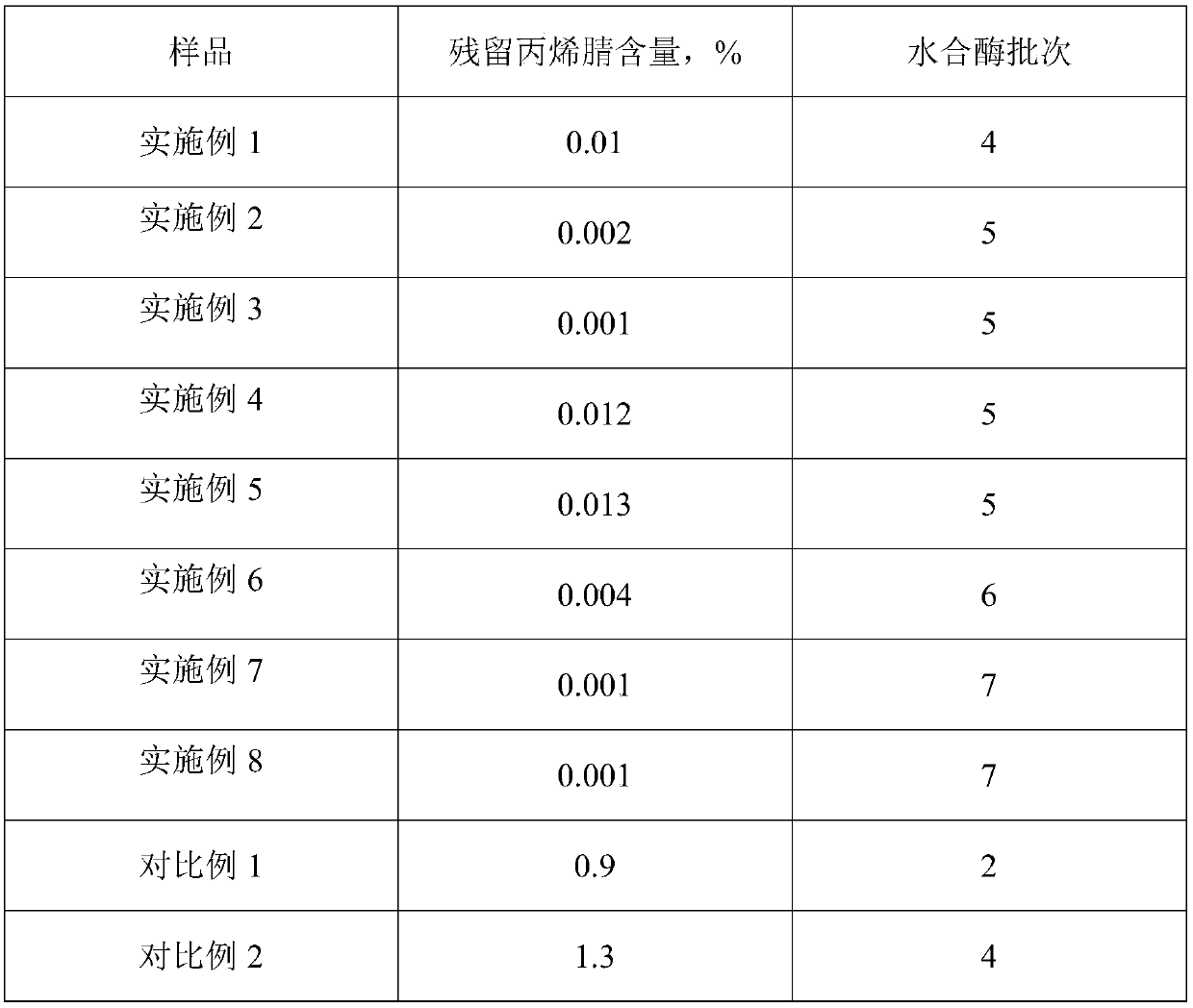

Embodiment 1

[0033] The ammonia nitrogen ratio is 1.0, the pH of the upper part of the quench tower is 3, the pH of the lower end of the quench tower is 8, the pH of the large cycle is 6.5, the temperature of the recovery tower is controlled at 75°C, the pH of the acrylonitrile of the finished product tower is controlled at 6.3, and the type of defoamer contains 1 %polyoxypropylene ether of polyoxyethylene, the molecular weight of the defoamer is 3500, the molecular weight distribution is 1.0, the addition of the defoamer is controlled to be 10ppm, and the acrolein content in the finally obtained acrylonitrile is 12ppm, and the oxazole content is 4ppm. The total cyanide content is 1ppm, and the residual amount of defoamer is 7ppm.

Embodiment 2

[0035] The ammonia nitrogen ratio is 1.2, the pH of the upper part of the quench tower is 4, the pH of the lower end of the quench tower is 9, the pH of the large cycle is 7.5, the temperature of the recovery tower is controlled at 85°C, the pH of the acrylonitrile in the finished tower is controlled at 7, and the type of defoamer contains 5 The polyoxypropylene ether of % polyoxyethylene, the molecular weight of defoamer is 4000, and molecular weight distribution is 1.2, and defoamer addition control is 20ppm, and the acrolein content in the acrylonitrile that finally obtains is 14ppm, and oxazole content is 7ppm, The total cyanide content is 5ppm, and the residual amount of defoamer is 9ppm.

Embodiment 3

[0037] The ammonia nitrogen ratio is 1.1, the pH of the upper section of the quench tower is 5, the pH of the lower end of the quench tower is 8, the pH of the large cycle is 7, the temperature of the recovery tower is controlled at 80°C, the pH of the acrylonitrile in the finished tower is controlled at 6.6, and the type of defoamer contains 2 %polyoxypropylene ether of polyoxyethylene, the molecular weight of the defoamer is 3700, the molecular weight distribution is 1.1, the addition of the defoamer is controlled to be 6ppm, and the acrolein content in the finally obtained acrylonitrile is 10ppm, and the oxazole content is 6ppm, The total cyanide content is 3ppm, and the residual amount of defoamer is 8ppm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com