Tea drink and manufacture method thereof

A manufacturing method and technology for tea beverages, which are applied in the directions of tea spice, tea, tea extraction, etc., can solve the problems of small amount of essence, poor aroma type, and thin tea soup taste, so as to reduce requirements, overcome the decline of product quality, and can choose strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

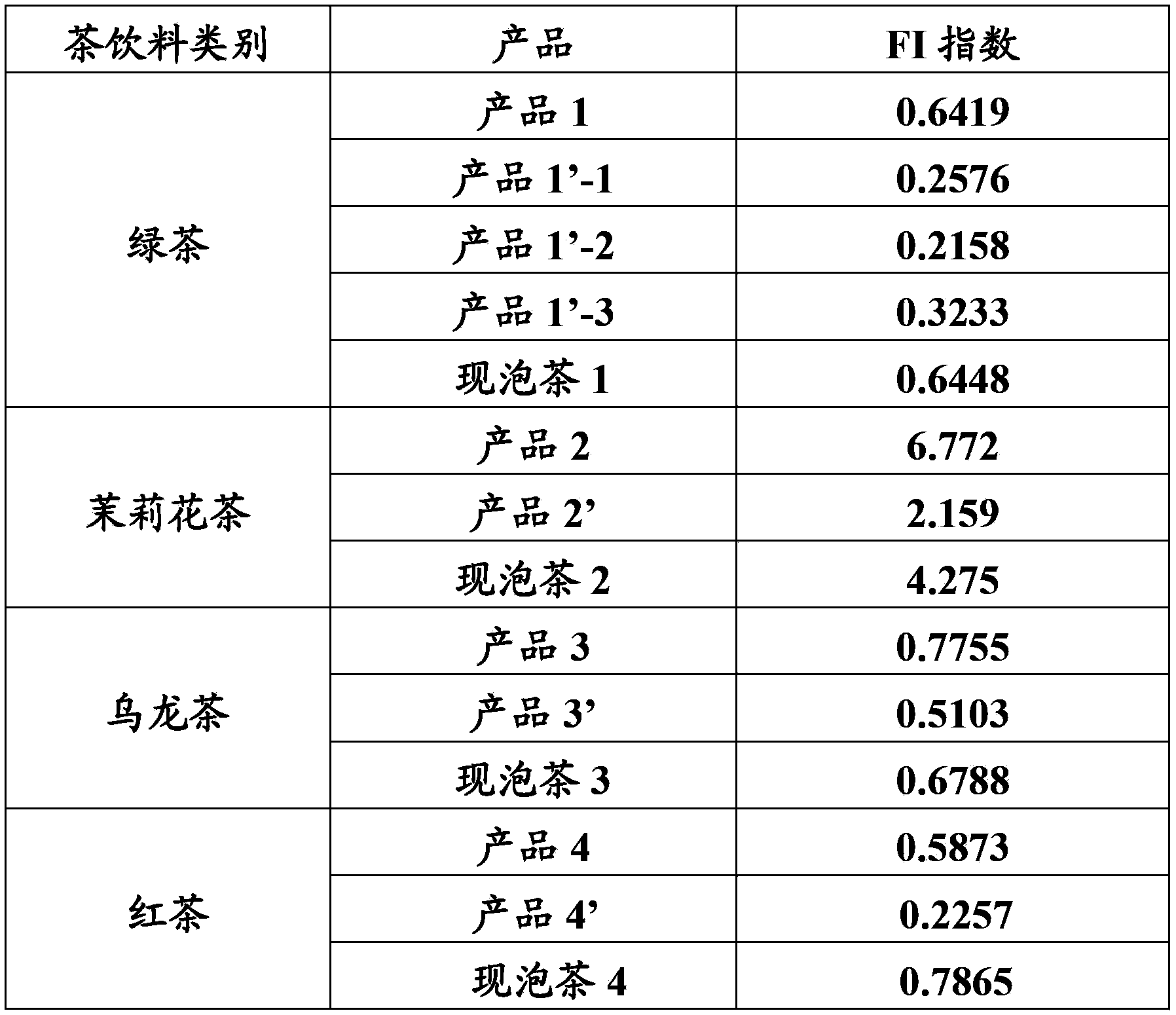

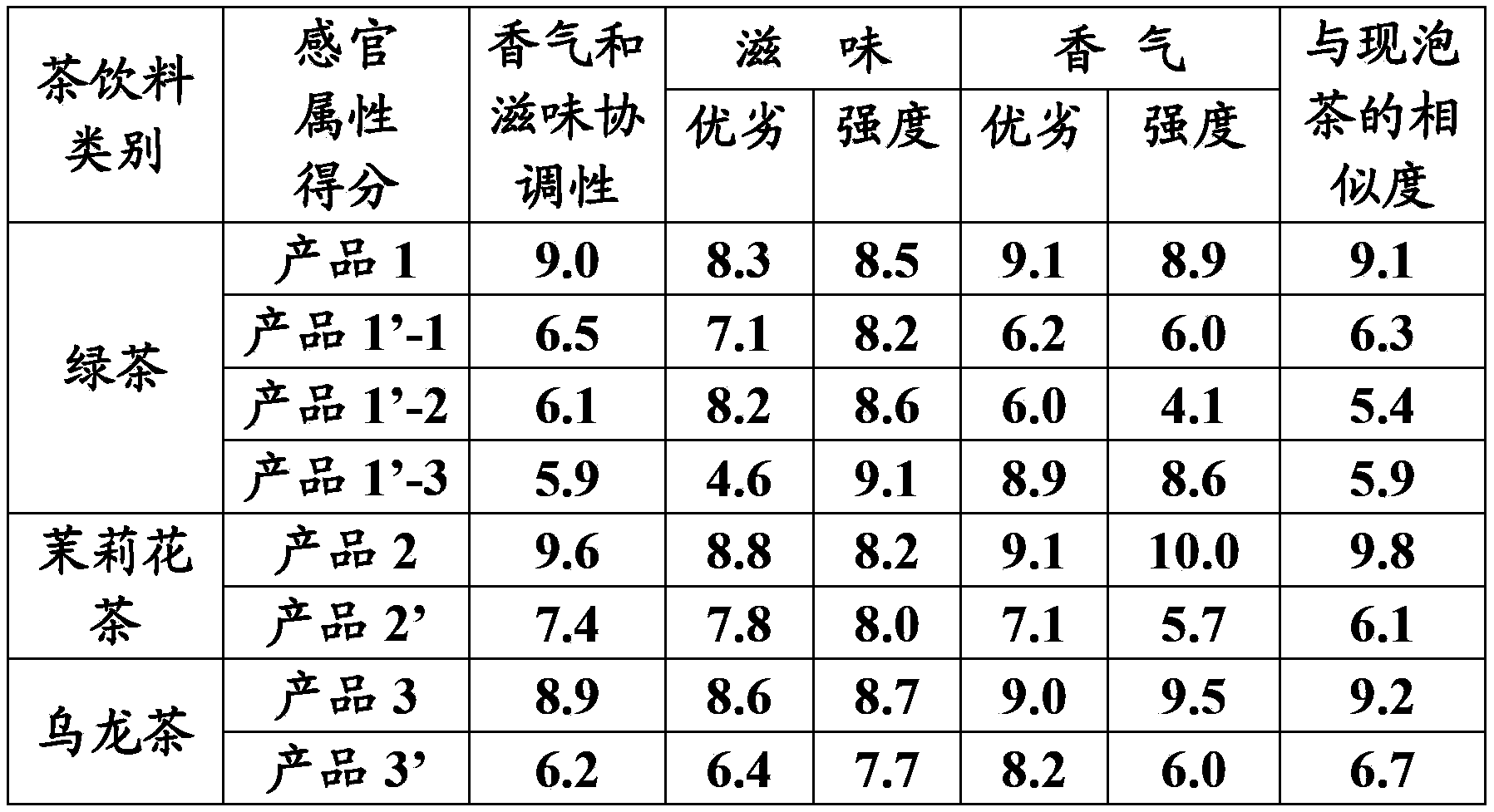

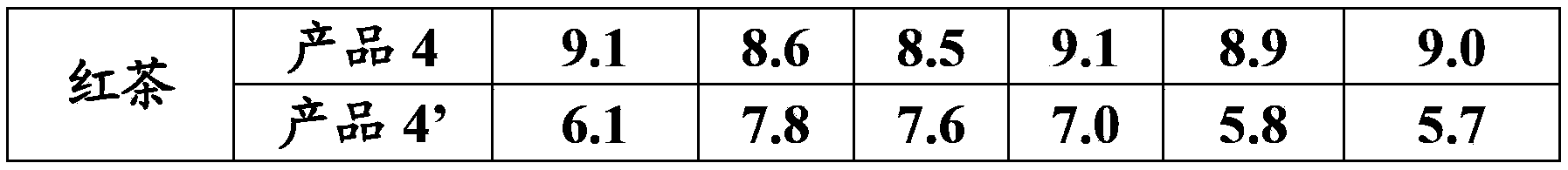

[0057] Embodiment 1: green tea beverage 1

[0058] Among the raw tea leaves, after evaluation and selection, the tea soup of Green Tea A (secondary fried green tea) tastes mellow and refreshing, and the type of aroma is good, but the intensity of the aroma is obviously not enough. For the test, the following conditions were selected for extraction: deionized water as the solvent, tea water ratio 1:70, 60°C, extraction for 20 minutes. The obtained extract was cooled and allowed to stand and then centrifuged to obtain 3.6 tons of the first clarified extract.

[0059]At the same time, among the raw tea leaves, green tea B (three-grade fried green tea) has a good aroma type and high aroma content, but the content of the tea soup is low and the taste is weak. Therefore, 50kg of green tea B is used as the second extract of the tea. Using raw materials, after testing, SCC-1000 rotating cone column equipment is used for aroma extraction. The extraction parameters are: tea leaves are ...

Embodiment 2

[0068] Embodiment 2: jasmine tea beverage

[0069] Among the raw tea leaves, the taste of jasmine tea A (second-grade jasmine tea) is mellow and fresh, and the type of aroma is good, but the intensity of aroma is not enough. 50kg of jasmine tea A was used as the raw material for extracting the first tea extract. After testing, the following conditions were selected for extraction: deionized water as solvent, tea water ratio 1:55, 75°C, extraction for 15 minutes. The obtained extract was cooled and allowed to stand and then centrifuged to obtain 2.9 tons of the first tea extract of clarification.

[0070] At the same time, jasmine tea A50kg is used as the raw material for extracting the second extract of tea leaves. After testing, a single-effect concentrator carries out aroma extraction. The extraction parameters are: the tea leaves are pulverized to a particle size of ≤1mm, and the weight of dry tea leaves accounts for 1% of the total weight of tea slurry. Add 1.5% water and...

Embodiment 3

[0074] Embodiment 3: Oolong tea beverage

[0075] Among the raw tea leaves, after evaluation and selection, the tea soup of Oolong tea A (second-level Luzhou-flavored Tieguanyin) tastes strong and refreshing, but the type of aroma is not good. Select the following conditions for extraction: deionized water as solvent, tea water ratio 1:60, 80°C, extraction for 12 minutes. The obtained extract was cooled and allowed to stand and centrifuged to obtain 3.1 tons of the first clarified extract.

[0076] At the same time, among the raw tea leaves, oolong tea B (fourth-grade Luzhou-flavored Tieguanyin) has a good aroma type and high aroma content, but the taste of the tea soup is rough and astringent. Therefore, 50kg of oolong tea B is used as the raw material for the second extract of tea , after testing, using SCC-1000 rotating cone column equipment for aroma extraction, the extraction parameters are: tea leaves are crushed to a particle size ≤ 1mm, and the amount of dry tea leave...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com