Drilling and milling screw tap

A tap, drilling and milling technology, applied in the field of tool manufacturing, can solve problems affecting product quality, process dispersion, rough inner surface of holes, etc., and achieve the effect of improving processing efficiency and processing quality, improving work efficiency, and ingenious structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

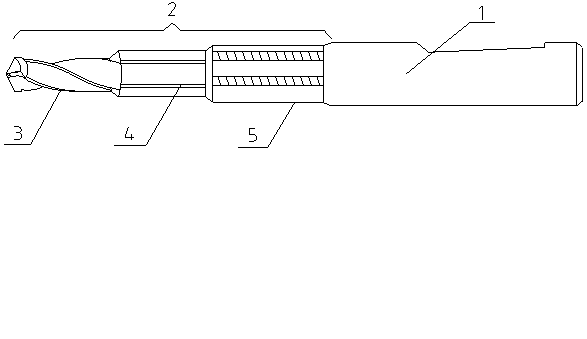

[0012] like figure 1 As shown, the drilling and milling tap of this embodiment includes a shank 1 and a blade 2 installed at the end of the shank 1. The side edge 5 and the plate-shaped cutting edge 4 between the drilling edge 3 and the side edge 5 are formed, and the cutting edge 4 is parallel to the axis of the blade portion 2 .

[0013] When processing internal threads, firstly, the drilling edge 3 is in contact with the workpiece to drill the workpiece, and then the cutting edge 4 finely processes the inner wall of the hole to make the inner wall of the hole smooth, and finally the threaded side at the rear end The blade 5 is in contact with the workpiece, so that the drilled hole can be thread milled, and there is no need to change the tool during the whole working process, which ensures the coaxiality of the drilling process and the thread milling process, thereby improving the processing efficiency and processing quality.

[0014] Further, the outer diameters of the dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com