Automatic lifting device for paper cocooning frame

An automatic lifting and grid tufting technology, which is applied in hoisting devices, transportation and packaging, and clockwork mechanisms, etc., can solve the problems of slow manual hanging tufting speed, achieve simple structure, labor-intensive and time-consuming solutions, and reduce labor intensity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

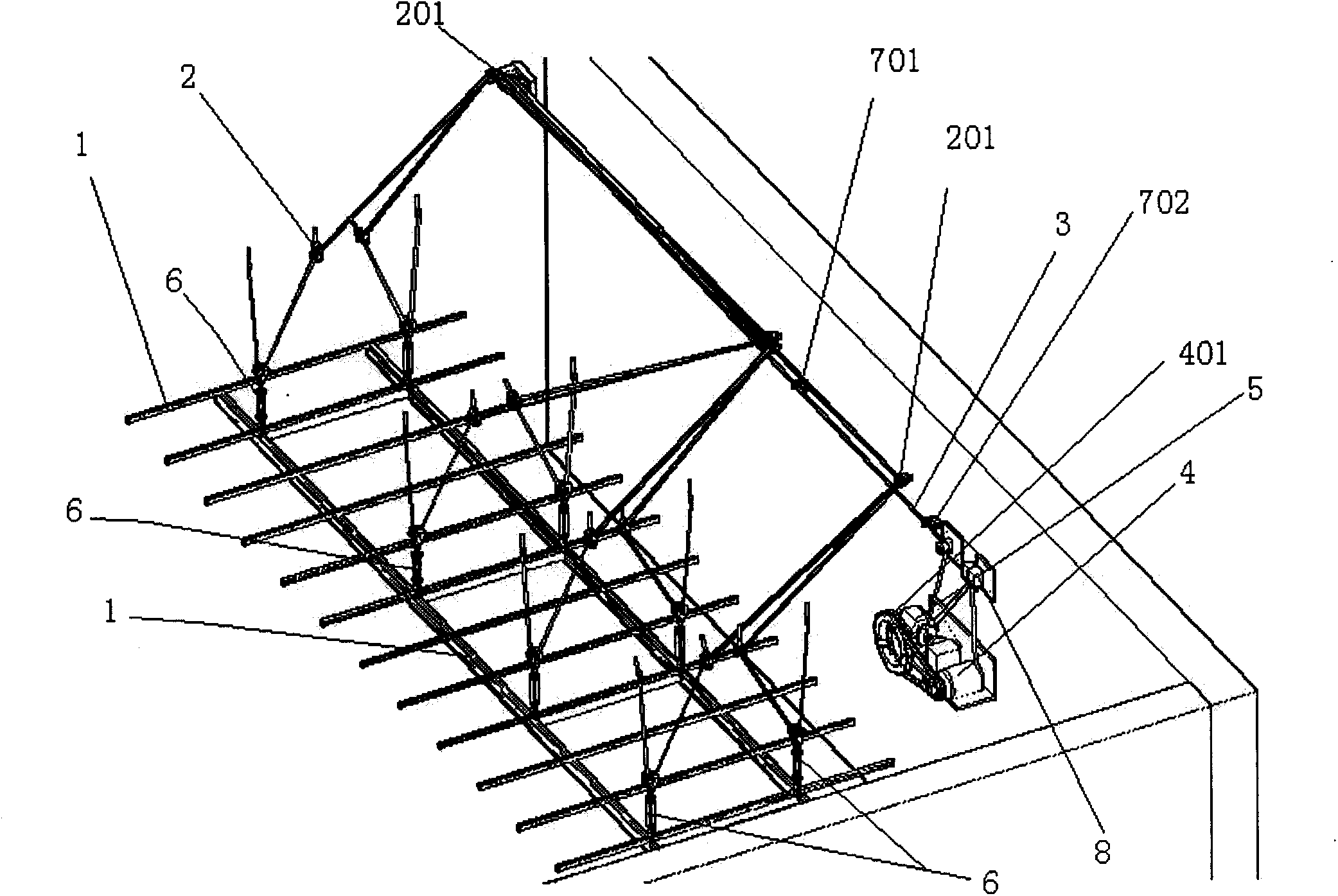

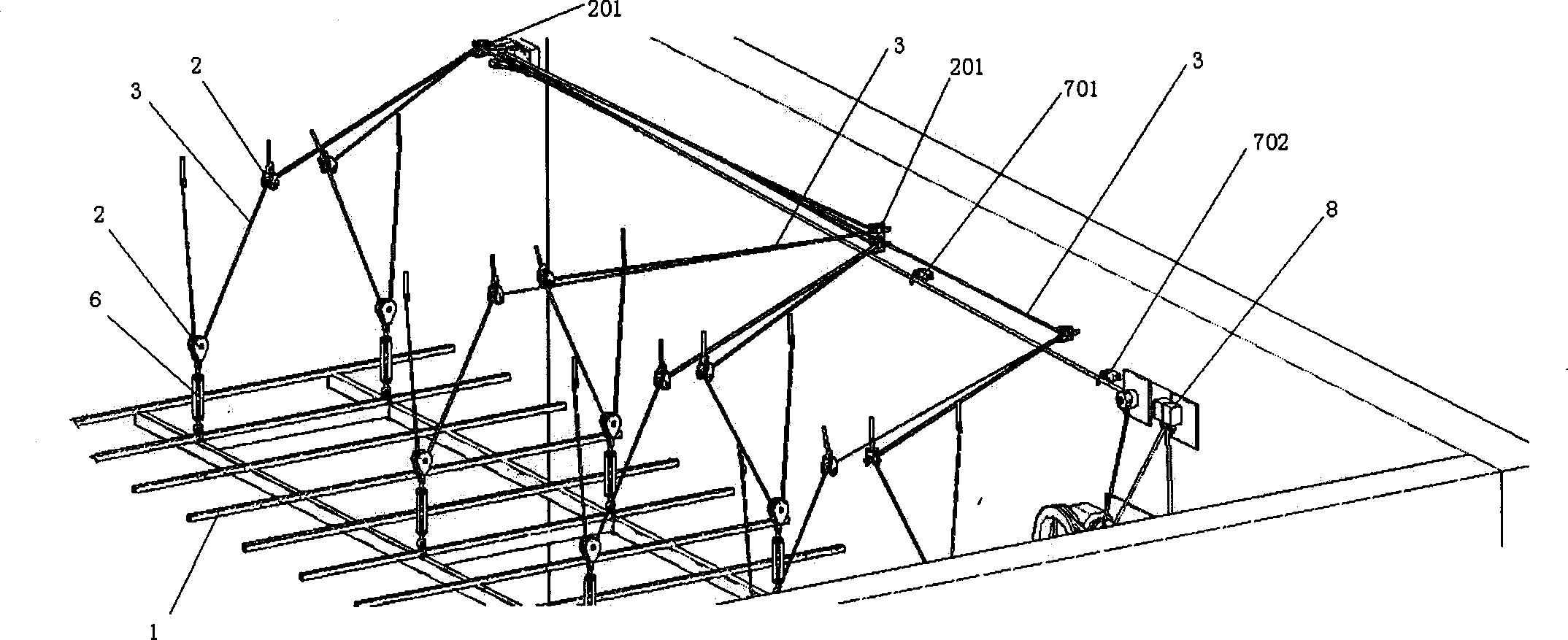

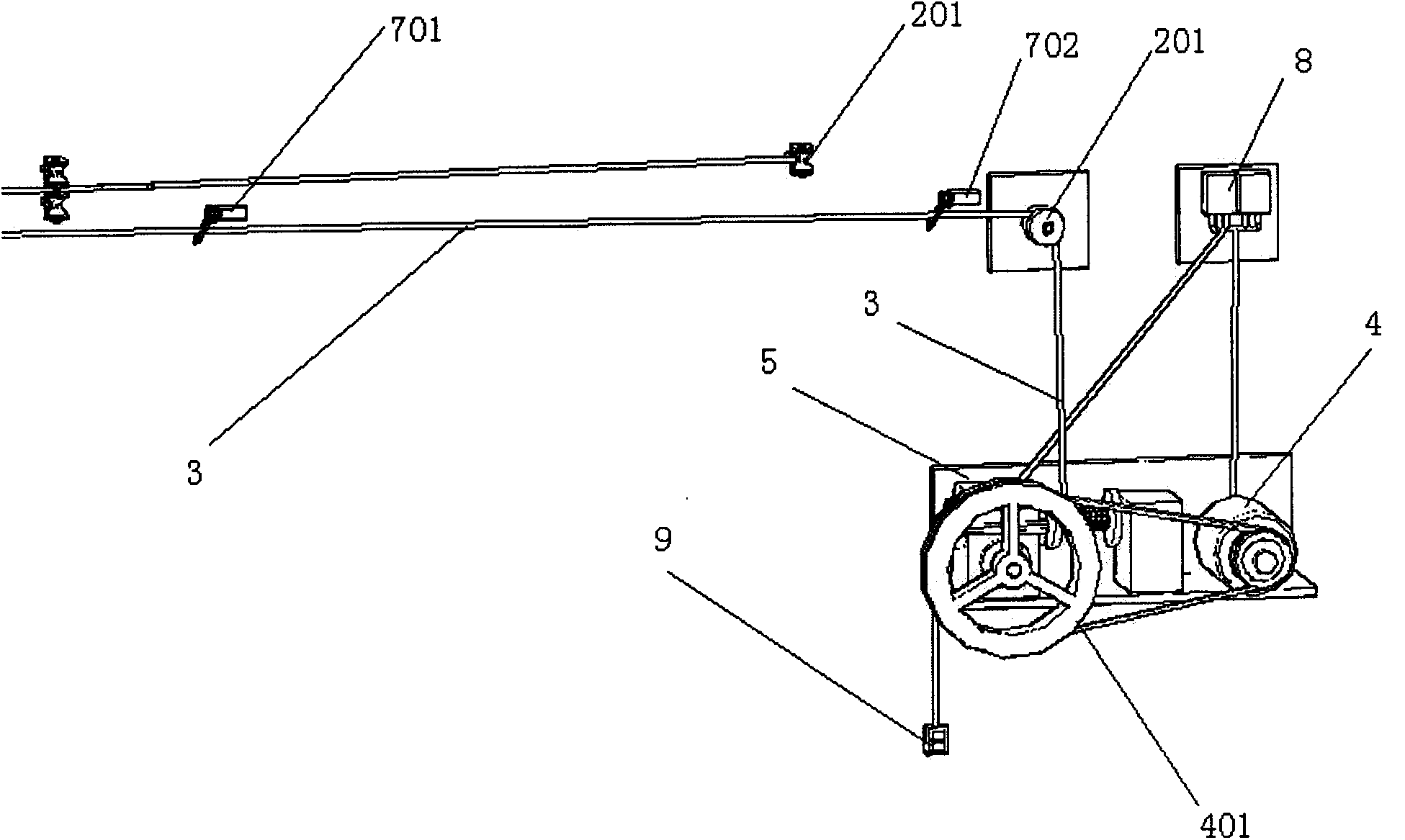

[0012] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments. In the embodiment, the metal rope 3 is made of iron material, the cluster frame 1 is made of iron pipe, the motor 4, the reducer 5, two travel switches, and the corner pulley 201 are installed on the wall, and the fixed point of the movable pulley 2 On the ceiling, after purchasing other components, install them according to the above description and attached drawings.

[0013] Press the control box 9, the magnetic switch 8 is energized and works to provide the working voltage for the motor 4 and the reducer 5, the whole circuit is energized, the motor 4 is started, the metal rope 3 is released along the pulley, the cluster frame 1 descends, when the cluster frame 1 When descending to the lowest point, the contacts of the travel switch 701 are opened, the motor 4 stops automatically, and the cluster frame 1 stops automatically; The corner pulley...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com