Production method of float glass

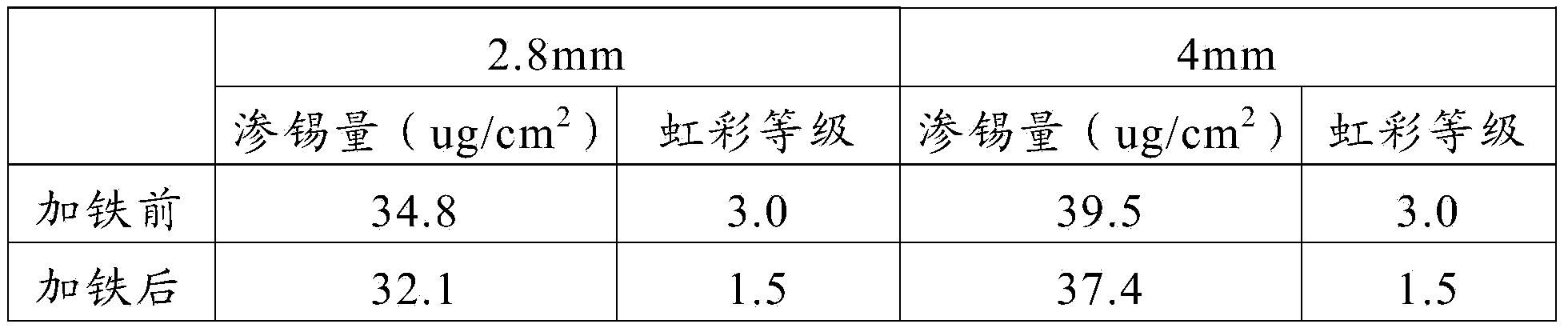

A production method and technology of float glass, which is applied in the field of float glass production, can solve the problems of fast cooling of tin liquid, high local concentration of iron, and easy generation of bubbles in float glass, etc., and achieve the effect of less bubbles and small amount of tin penetration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] The preparation method of described tin bath additive preferably comprises the following steps:

[0025] Mix 18-48.8wt% tin and 51.2-82wt% iron and vacuum arc melting to obtain a master alloy with uniform composition;

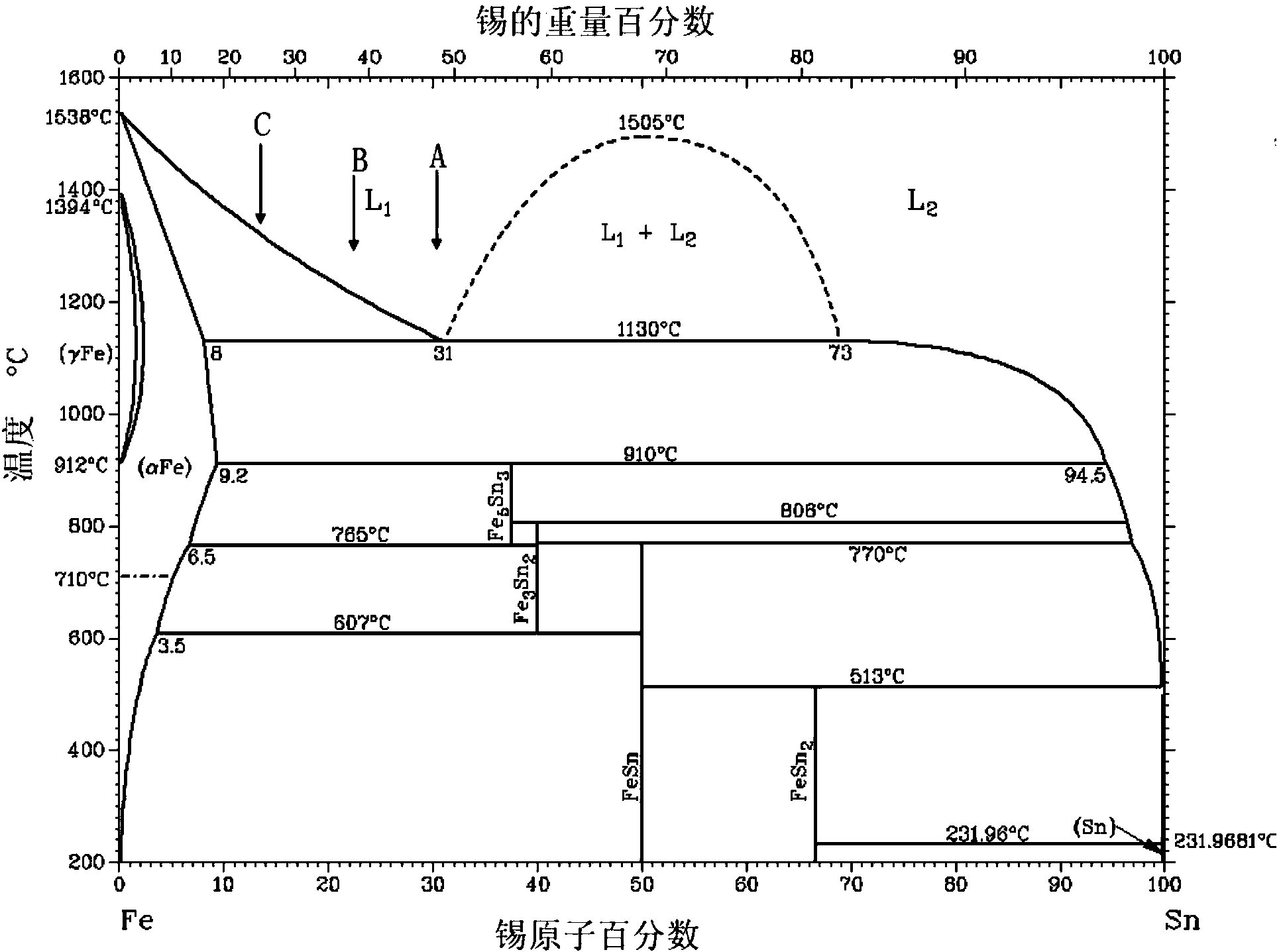

[0026] The master alloy is granulated to obtain a tin bath additive with a tin content of 18-48.8% by mass and a melting point of 1130-1400°C.

[0027] The present invention uses tin and iron as raw materials, and first mixes them according to the mass ratio. The mass percentage of the tin is 18-48.8wt%, preferably 25-38wt%, more preferably 28-35wt%. The mass percentage of the iron is 51.2-82wt%, preferably 62-75wt%, more preferably 65-78wt%.

[0028] After the tin and iron are mixed, they are vacuum arc melted to obtain a master alloy with a uniform composition. The vacuum arc melting is preferably carried out in an inert gas protection, and the inert gas is preferably argon. The air pressure of the vacuum arc melting is preferably 0.02-0.04 MPa. In...

Embodiment 1

[0034] After mixing 488 grams of tin and 512 grams of iron, use gas shielded arc melting, repeated melting to obtain an alloy with uniform composition;

[0035] The master alloy was placed in a mechanical device and shaped to obtain a tin bath additive with a particle size of 3mm.

Embodiment 2

[0038] After mixing 380 grams of tin and 620 grams of iron, use gas shielded arc melting, repeated melting to obtain an alloy with uniform composition;

[0039] The master alloy was placed in a mechanical device and shaped to obtain a tin bath additive with a particle size of 3 mm.

[0040] According to the phase diagram, the equilibrium structure of the tin bath additive is hypomotectic, with a large number of agglomerated α-Fe particles and FeSn phases, and its melting point is 1216°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com