Saturated Precursor Dilution Method for Preparation of Zinc Oxide with Micro-nano Composite Morphology

A zinc oxide and composite technology, applied in the direction of zinc oxide/zinc hydroxide, nanotechnology, nanotechnology, etc., can solve the problems of low production and difficult industrialization promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Method of the present invention can be summarized as follows:

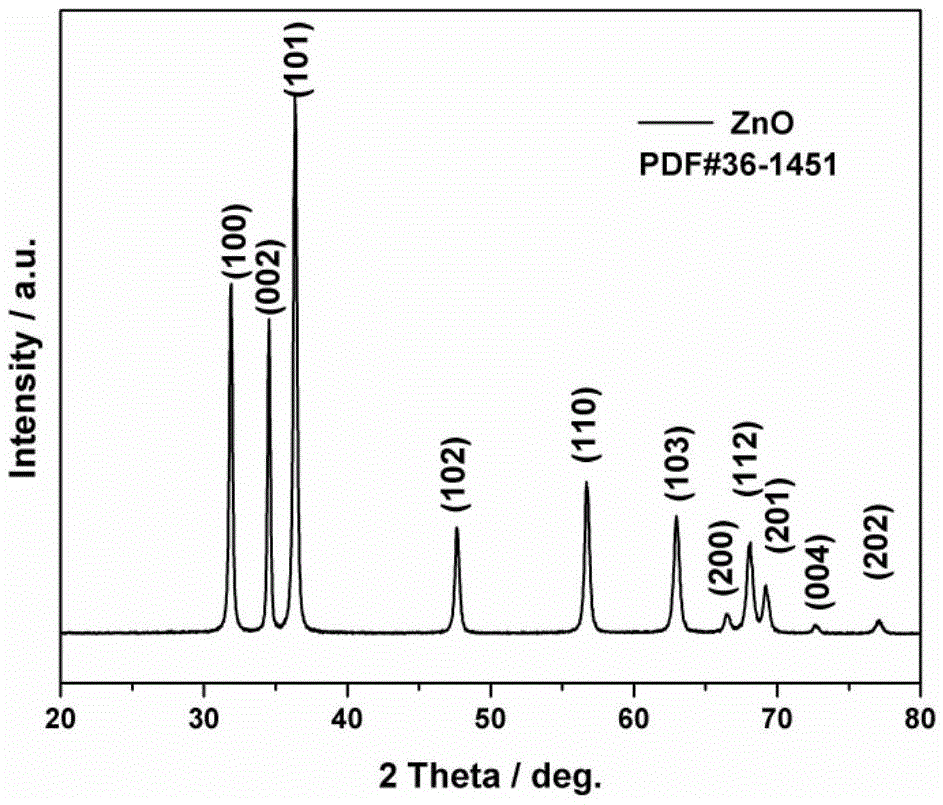

[0043]Firstly, zinc oxide has a dual nature of acid and alkali, and metazincate is easily hydrolyzed in water environment to synthesize a yucca-like zinc oxide cluster powder. The method used is called saturated precursor solution dilution method. Then zinc oxide is quantitatively mixed with the paint, and the adhesiveness of the paint is used to prepare a relatively firm and dense film. Combined with the roughened configuration of ZnO, combined with simple and rapid surface fatty acid modification, a superhydrophobic interface is constructed.

[0044] 5.1 Controllable preparation of ZnO nanoclusters

[0045] 5.1.1

[0046] First, prepare a saturated solution of strong alkali, prepare a certain volume (or higher) of nearly saturated aqueous sodium hydroxide solution (3-30mol / L) in a plastic beaker, stir evenly to form a clear solution, and keep stirring. Then, a certain amount of commercial zinc oxide po...

Embodiment 2

[0059] Low temperature controllable preparation of ZnO structure

[0060] According to the technical content 5.1.1 of Example 1, a saturated precursor solution was prepared, the concentration of sodium hydroxide was 15 mol / L, and the mass ratio of zinc oxide to sodium hydroxide was 1:10.

[0061] According to technical content 5.1.2, the dilution factor is 5 times during the water bath reaction, the reaction temperature is 45°C, and the reaction time is 1 hr.

[0062] According to technical content 5.1.3, after the reaction is completed, the white turbid reaction solution is cooled rapidly, washed several times with deionized water and absolute ethanol, and then dried in an oven at a drying temperature of 80°C. Collect the synthesized zinc oxide powder.

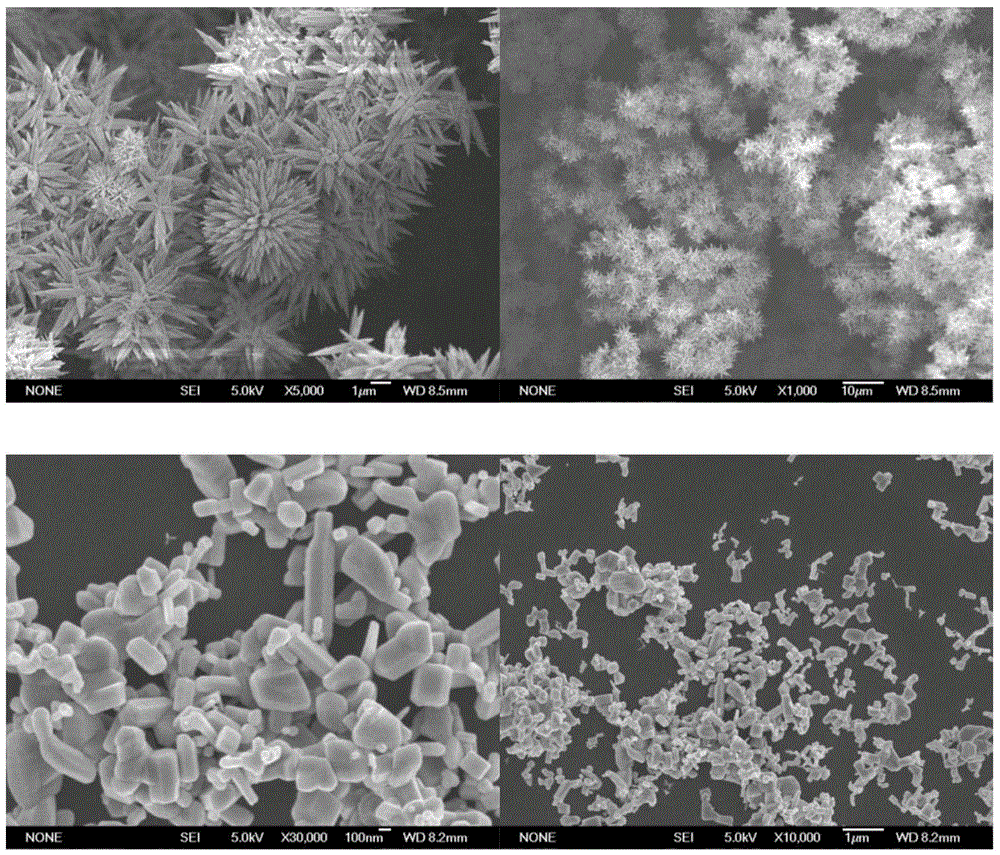

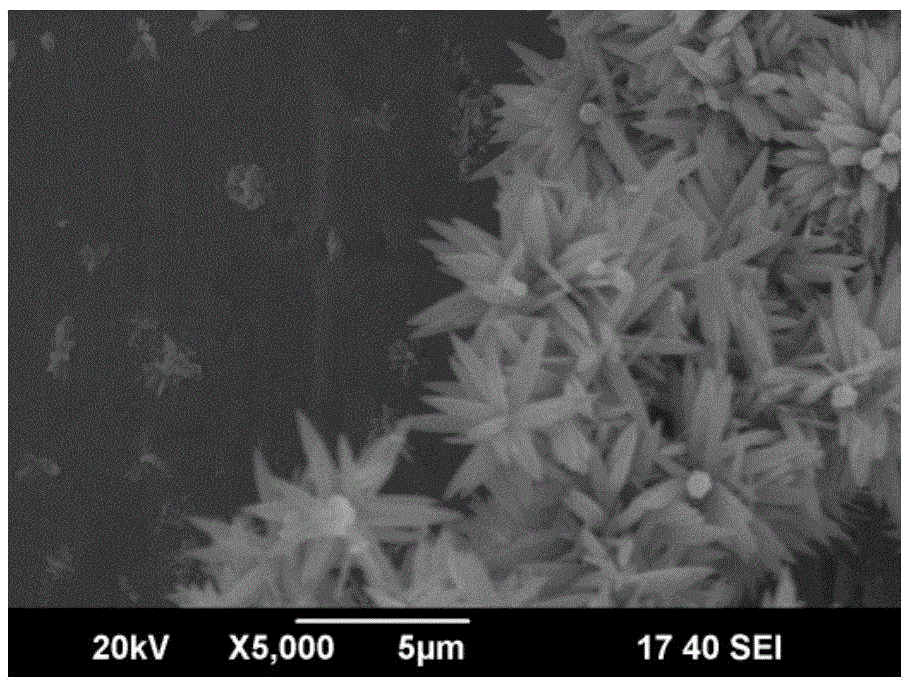

[0063] Experimental results: if figure 2 As shown in (right), when heated and stirred for 1 hr, the product is a single cluster structure, which is composed of needle-like nanorods, similar to the plant yucca in nature. A...

Embodiment 3

[0065] High-temperature controllable preparation of ZnO structures

[0066] According to the technical content 5.1.1 of Example 1, a saturated precursor solution was prepared, the concentration of sodium hydroxide was 15 mol / L, and the mass ratio of zinc oxide to sodium hydroxide was 1:10.

[0067] According to technical content 5.1.2, the dilution factor is 7 times, the reaction temperature is 75°C, and the reaction time is 5 minutes and 45 minutes respectively.

[0068] According to technical content 5.1.3, after the reaction is completed, the white turbid reaction solution is cooled rapidly, washed several times with deionized water and absolute ethanol, and then dried in an oven at a drying temperature of 80°C. Collect the synthesized zinc oxide powder.

[0069] Experimental results: if Figure 4 (Left), after 5 minutes of reaction, the cluster structure has basically been formed, but some smaller needle-tip nanorod structures are still growing. After 45 minutes of reac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com