Novel medical polyethylene glycol (PEG) functional material

A technology of polyethylene glycol and functional materials, applied in the fields of polymer chemistry and polymers, to achieve the effect of reducing toxic and side effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] ①Preparation of star block copolymer

[0026] Using ethylene oxide as raw material, three-arm or multi-arm star-shaped polyethylene glycol was synthesized by classic alkali method ring-opening. Due to the existence of hydroxyl groups at the end of the polymer, glycine protected by amino Boc-groups can be used. Under the catalysis of DCC / HOBt, it reacts with SPEG to generate SPEG derivatives. In trifluoroacetic acid / dichloromethane solution, the amino group of the above product is de-Boc-protected, and the star-shaped macromolecular initiator SPEG-NH with amino-terminated functional groups is obtained. 2 . The macroinitiator and O-tert-butyl-L-threonine carboxylic acid anhydride (NCA) are subjected to ring-opening polymerization in a certain ratio to obtain poly-O-tert-butyl-L-threonine with PEG as the core star block polymers.

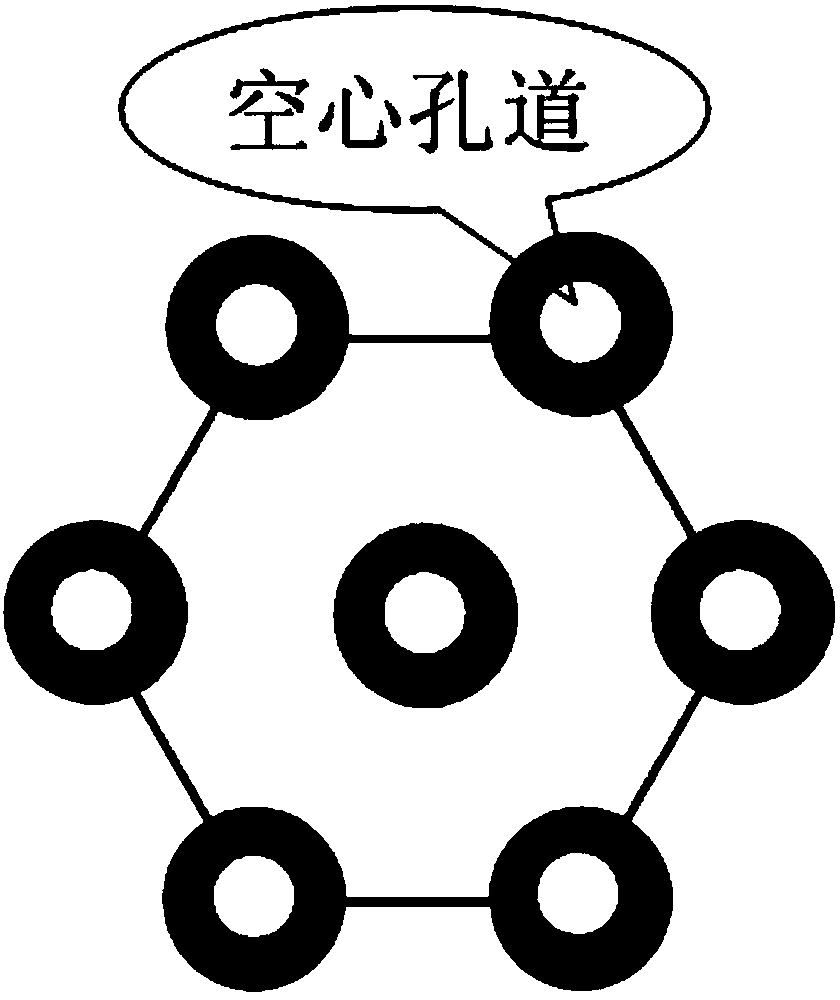

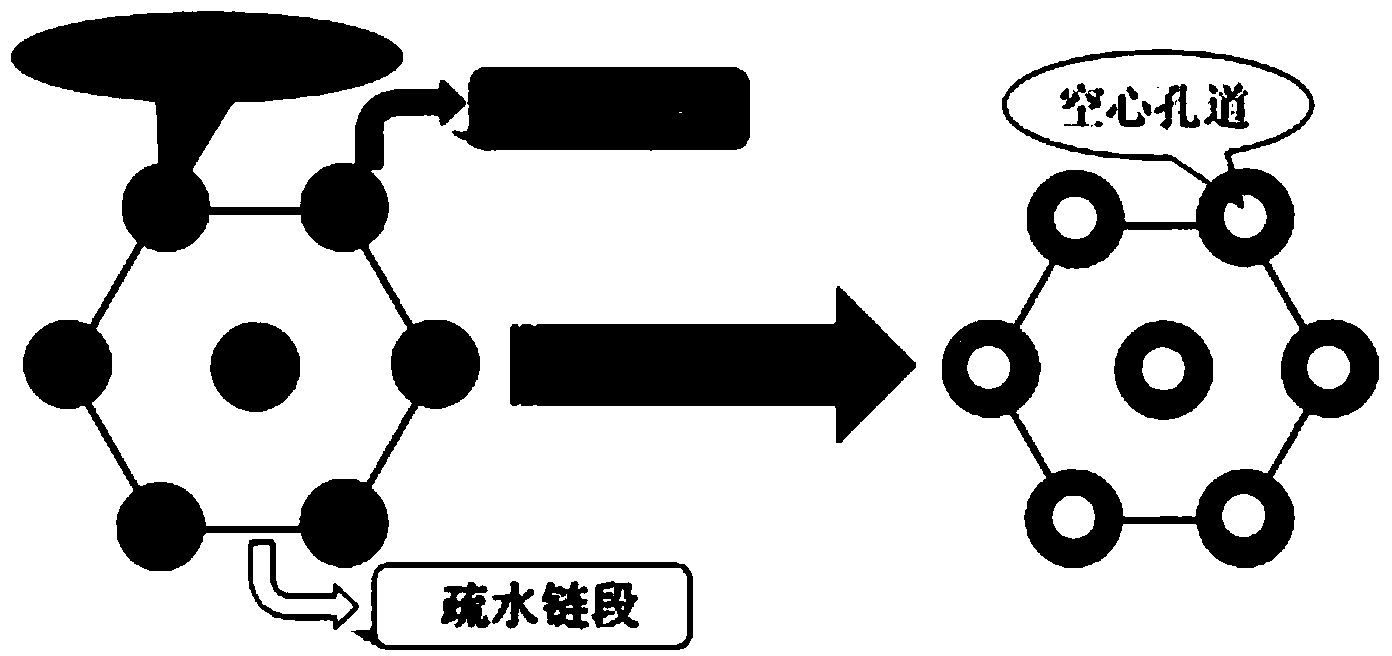

[0027] ②Characterization of the self-assembled structure and properties of star-shaped block copolymer materials

[0028] The chemical struc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com