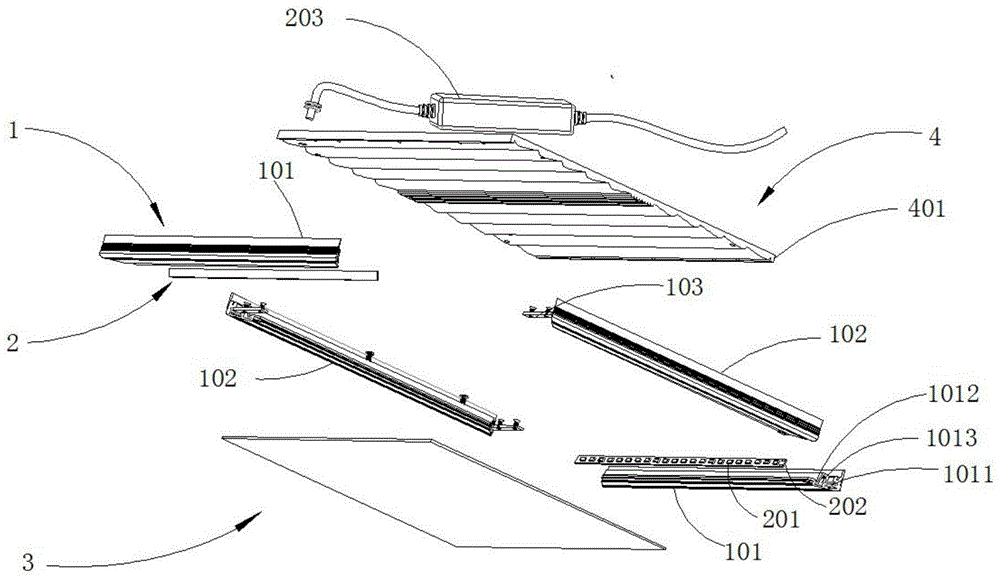

a led panel light

A technology of LED panel light and LED light source, which is applied in the field of LED lighting, can solve the problems of enlarging LED light source and diffusion plate, making it difficult to fix and locate, and increasing the difficulty of heat dissipation, so as to achieve broad application prospects, facilitate heat dissipation, and save space Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

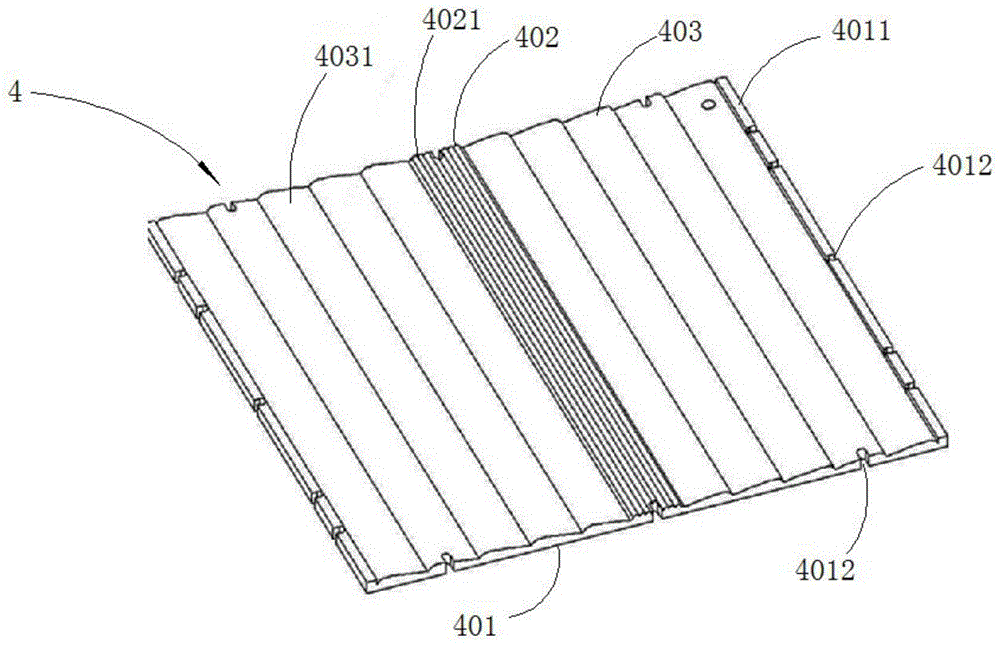

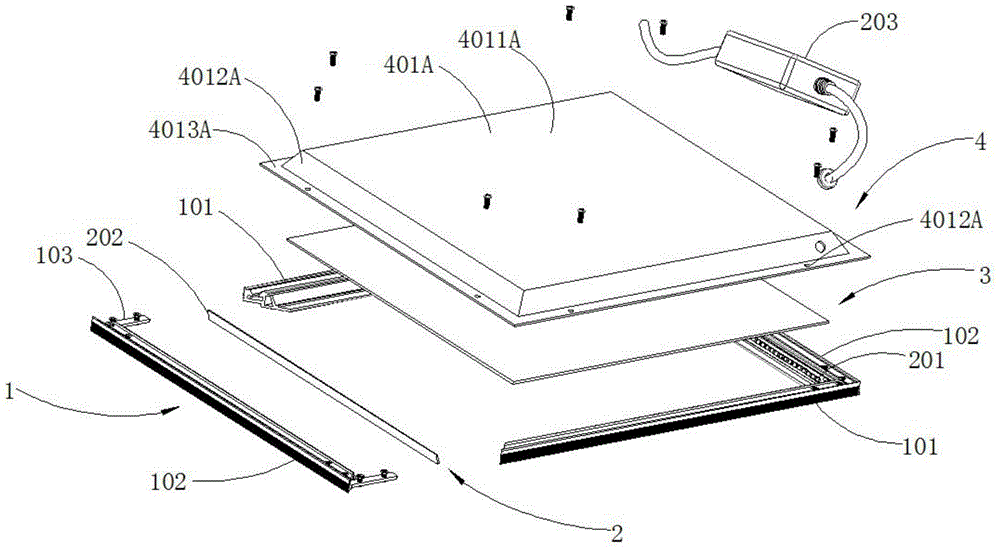

[0075] In Embodiment 1, the base plate 401 is a horizontal plate, the base plate 401 further includes two connecting plates 4011, the diffuser 402 is arranged in the middle of the base plate 401, the two connecting plates 4011 are arranged at the two ends of the base plate 401, and the two light guides 403 The diffusing part 402 and the connecting plate 4011 are respectively arranged between the two diffusing parts 402 and the connecting plate 4011 , and the two light guide parts 403 and the two connecting plates 4011 are symmetrical about the central line of the diffusing part 402 . Wherein, the connecting plate 4011 is a cuboid, and the length of the connecting plate 4011 is consistent with the lengths of the light guiding part 403 and the diffusing part 402 .

[0076] In order not to generate light spots, to make the reflective effect of the reflective plate 4 better, and to achieve the effect of uniform light output in a large area, the inventors made improvements to the LE...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com