Convex lens focal length measuring device and method

A measuring device and a convex lens technology, applied in the field of convex lenses, can solve the problems of many optical elements, large influence of measurement results, complicated mechanism, etc., and achieve the effect of simple equipment and intuitive interference pattern.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

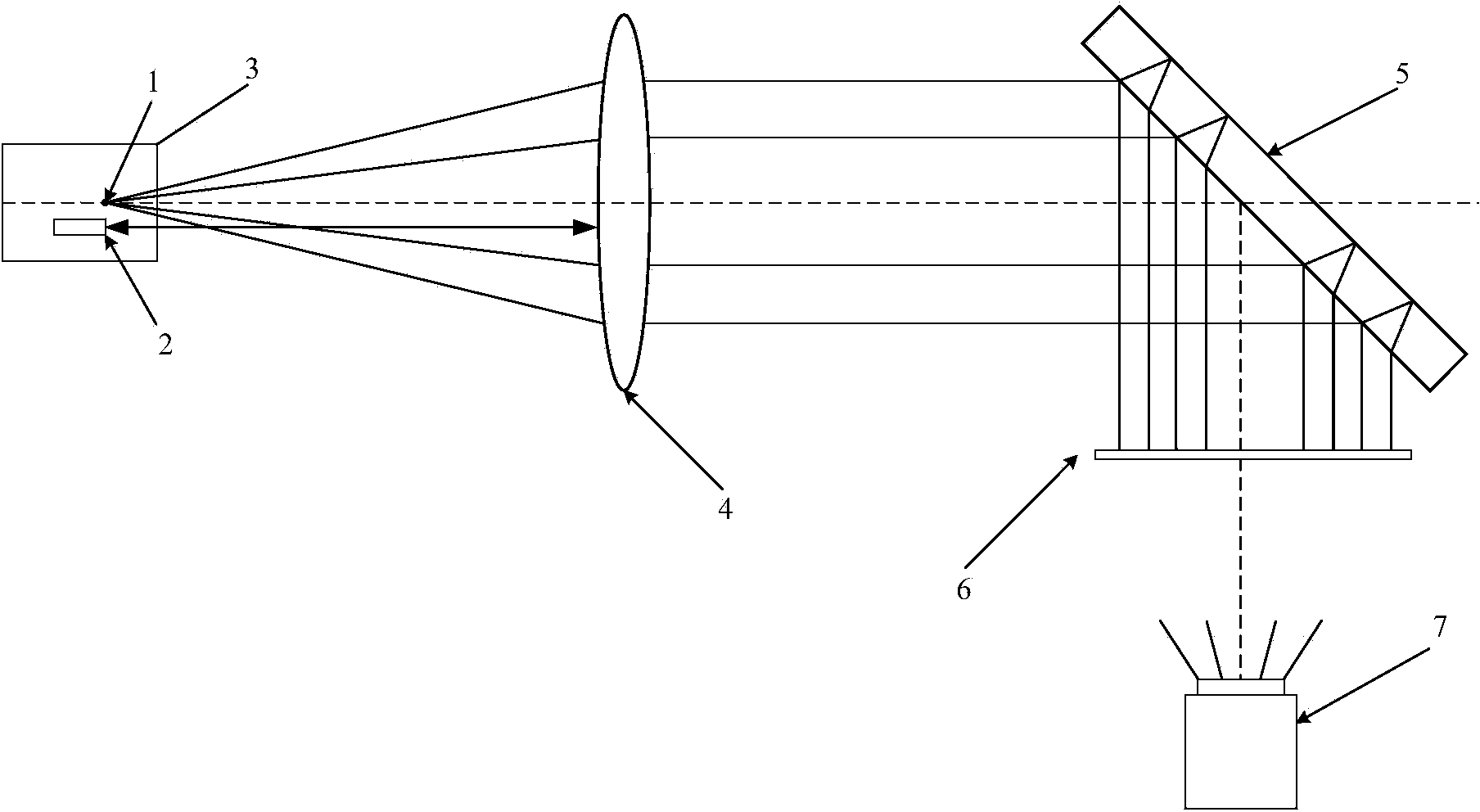

[0040] Such as figure 1 As shown: the convex lens focal length measuring device of the present invention is composed of 1053nm optical fiber point light source 1, laser range finder 2, precision moving guide rail 3, convex lens to be measured 4, shearing interference plate 5, ground glass screen 6 and CCD7:

[0041] The point light source 1 is an optical fiber point light source with a core diameter of 5.8 μm;

[0042] The optical fiber point light source 1 and the laser range finder 2 are installed on the same adjustment frame, and the adjustment frame has an overall lifting, pitching and left and right movement adjustment mechanism. The measurement zero point of the optical fiber point light source 1 and the laser rangefinder 2 is guaranteed to be in the same plane perpendicular to the optical axis of the lens to be measured.

[0043] The adjustment frame is fixed on the one-dimensional precision moving guide rail 3 for forward and backward translation, and the translation ...

Embodiment 2

[0061] Such as figure 1 As shown: the focal length measuring device of the convex lens of the present invention consists of a 1053nm point light source 1, a laser range finder 2, a precision moving guide rail 3, a convex lens to be measured 4, a shearing interference plate 5, a ground glass screen 6 and a CCD7:

[0062] The point light source 1 is an optical fiber point light source with a core diameter of 5.8 μm;

[0063] The optical fiber point light source 1 and the laser rangefinder 2 are installed on the same adjustment frame, which has an integral lifting, pitching and left and right movement adjustment mechanism. The measurement zero points of the optical fiber point light source 1 and the laser rangefinder 2 are guaranteed to be in the same plane perpendicular to the optical axis of the lens to be measured.

[0064] The adjustment frame is fixed on the one-dimensional precision moving guide rail 3 for forward and backward translation, and the translation direction is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Core diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com