Film residue recycling machine

A recycling machine and residual film technology, which is applied in the fields of collectors, agricultural machinery and implements, and applications, can solve the problems of difficult separation of crop rhizomes and residual film, increased separation and cleaning work, etc., and achieves considerable economic benefits and low recovery costs. , The effect of reducing the recovery time of residual film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

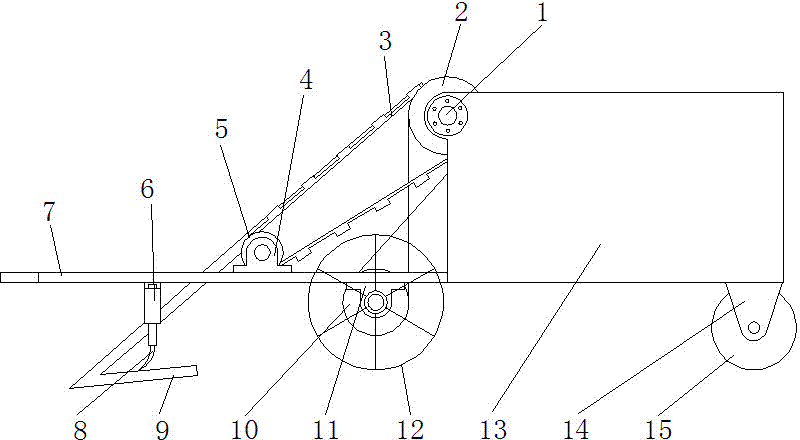

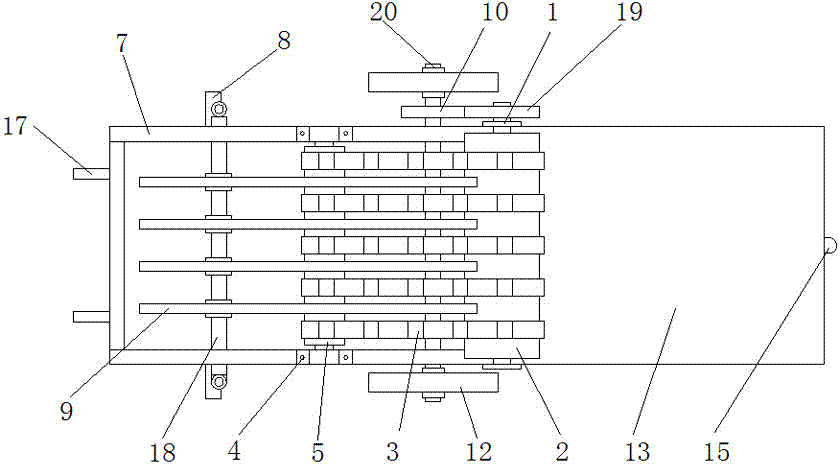

[0021] The walking direction of the device is the front end, that is, if figure 1 , 2 , 4, and 5 show the left side as the front end. Draw frame 17 is installed at the front end of frame 7, and this device links to each other with tractor by draw frame, drives its walking by tractor. Residual film collection box 13 is installed on the rear end of frame, and road wheel 12 is installed on frame both sides, and road wheel is fixedly installed on axle 20 two ends, and axle is installed on the frame by bearing block 11, as figure 2 As shown, a driving pulley 10 is fixedly installed on the upper side of the shaft;

[0022] A conveying device is installed on the frame between the residual film collection box and the traction frame. It forms a low front and high rear shape.

[0023] The driving wheel 2 is rotatably fixed on the residual film collecting box by the bearing fixing seats 1 on both sides of the residual film collecting box. The driven wheel is fixed by bearing blocks...

Embodiment 2

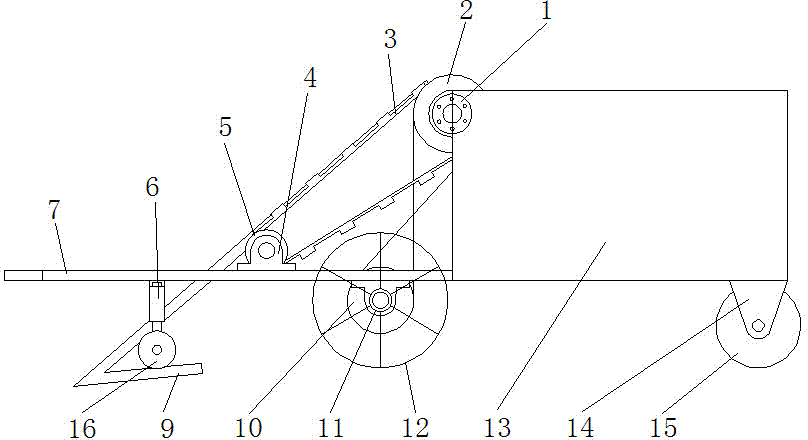

[0031] like image 3 As shown, on the basis of Embodiment 1, the soil removal shovel 8 is replaced with a disc-shaped film cutting knife 16, and the remaining film of all mulches in the farmland is cut to a set width by the film cutting knife, and then the remaining film is cut. Recycle. Simultaneously transmission chain is made up of the driving gear that is fixed on axle 20 upper side and the passive gear that is fixed on the fixed shaft upper side of fixed driving wheel 2, and driving leather gear and driven gear mesh with each other, drive driving wheel 2 rotations.

[0032] In the above embodiments, the spacing and quantity of the triangular film lifters 9 can be determined according to the width of the film. For increasing the frictional force of the strip conveyor belt 3, protrusions are evenly distributed on the strip conveyor belt.

[0033] In order to ensure the stability of the device in the walking process, a support wheel 15 is installed at the rear end of the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com