Oceanic drift netter

A technology for gillnets and fishing boats, applied in fishing boats, fishing nets, fishing, etc., can solve the problems of low degree of mechanical automation, small size of gillnet fishing boats, and small ship capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

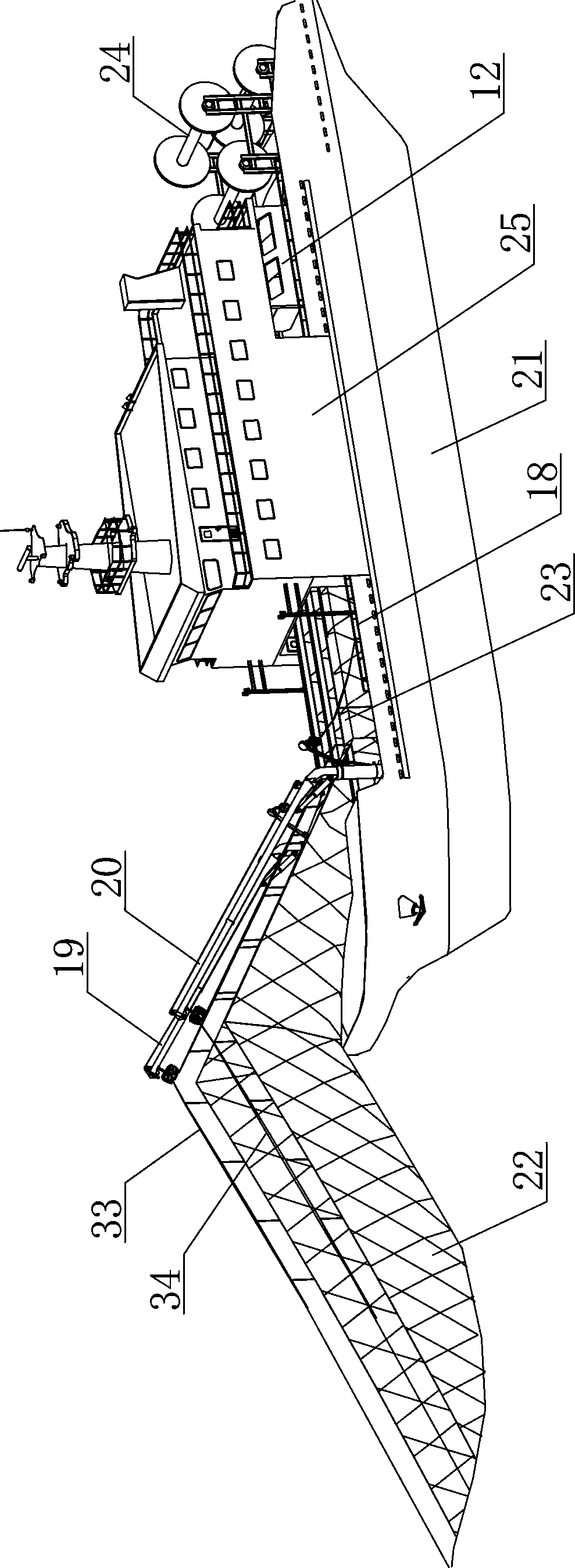

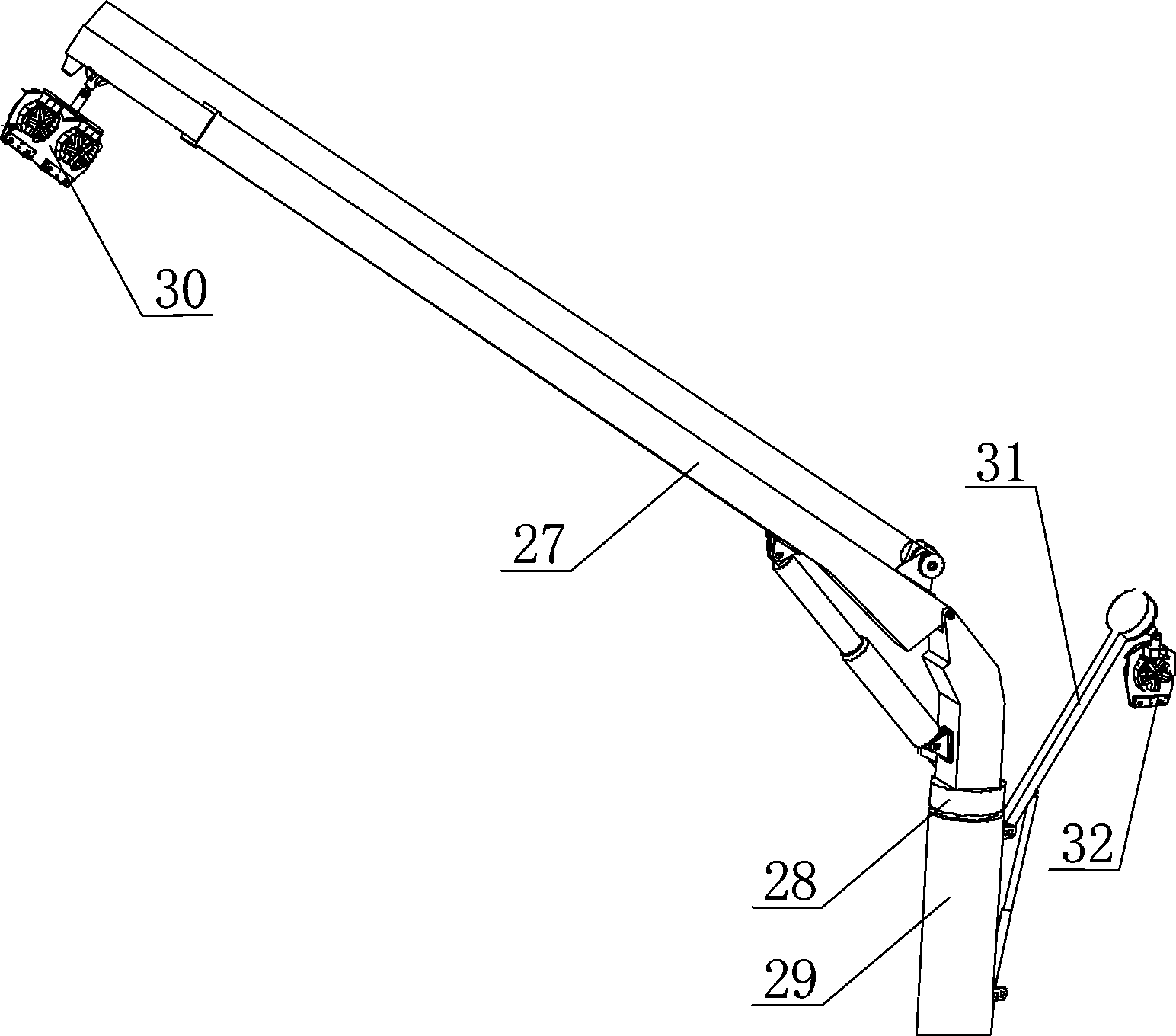

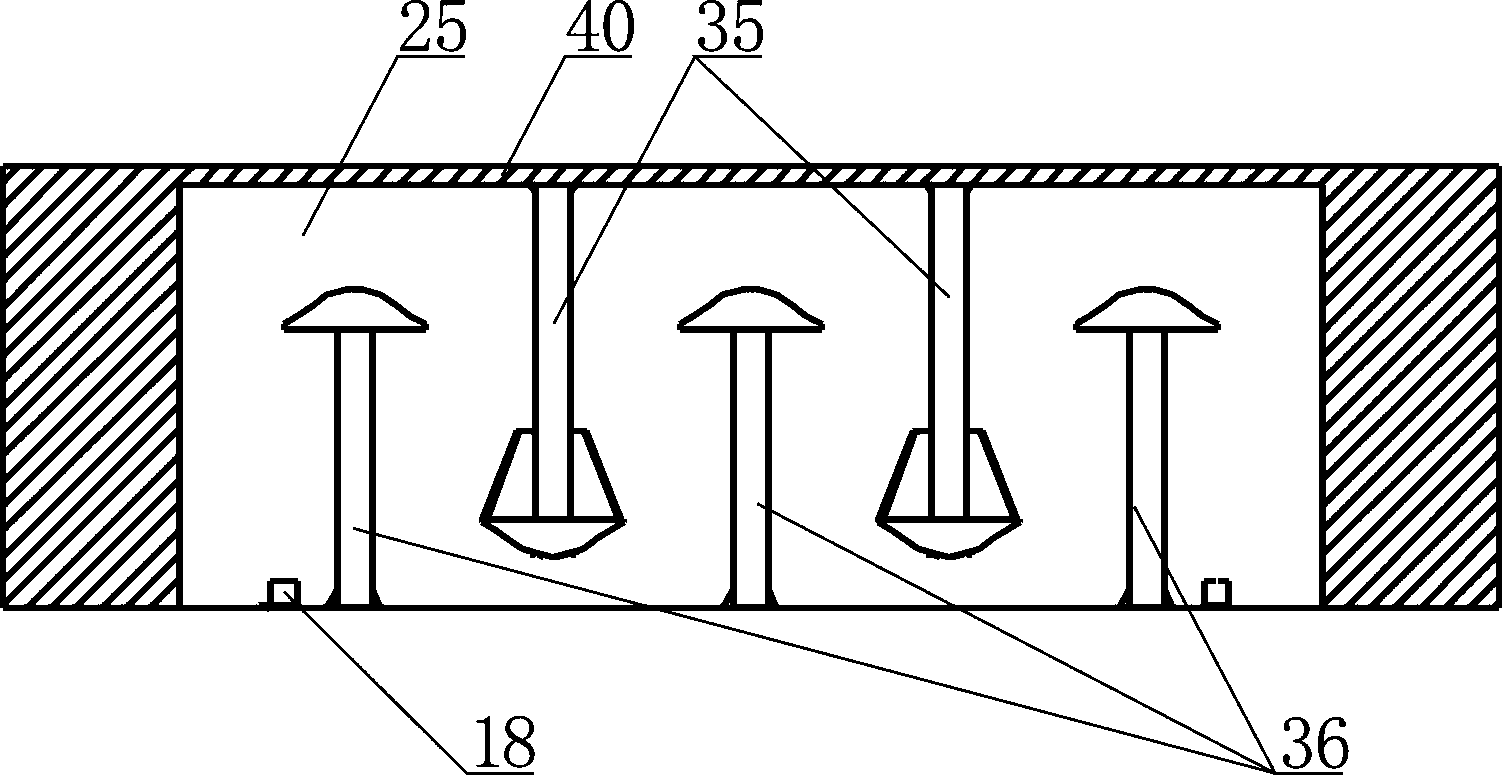

[0034] like figure 1Shown, a kind of oceanic flow gillnet fishing boat, it is mainly by hull 21, flow gillnet 22, crane 19, crane 20, two guide grooves 18, stretching net frame 23, high-pressure water spray net washing device, stacking net machine and throwing and netting machine 24, the deck of the hull 21 is provided with a fish solution working cabin 25 and a net washing room 12 successively from the bow to the stern, and the high-pressure water jet washing net device and the net stacking machine are located in the washing machine. In the net room 12, the guide net frame 23 is located in the fish solution work cabin 25, and stretches to the bow from the fish solution work cabin 25, and the crane 19 and the crane 20 are located on the deck of the bow, and the nets are thrown and managed. The machine 24 is located on the deck of the stern, and the two guide grooves 18 are distributed on the deck of the hull 21 at intervals parallel to each other, and pass through the fish-dis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com