Device for producing polyetheramine by using continuous method

A production device and technology of polyetheramine, which are applied in chemical instruments and methods, chemical/physical/physical chemical processes, chemical/physical processes, etc., can solve problems such as affecting the activity of catalysts, reduce the impact, increase production, and connect rationally Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

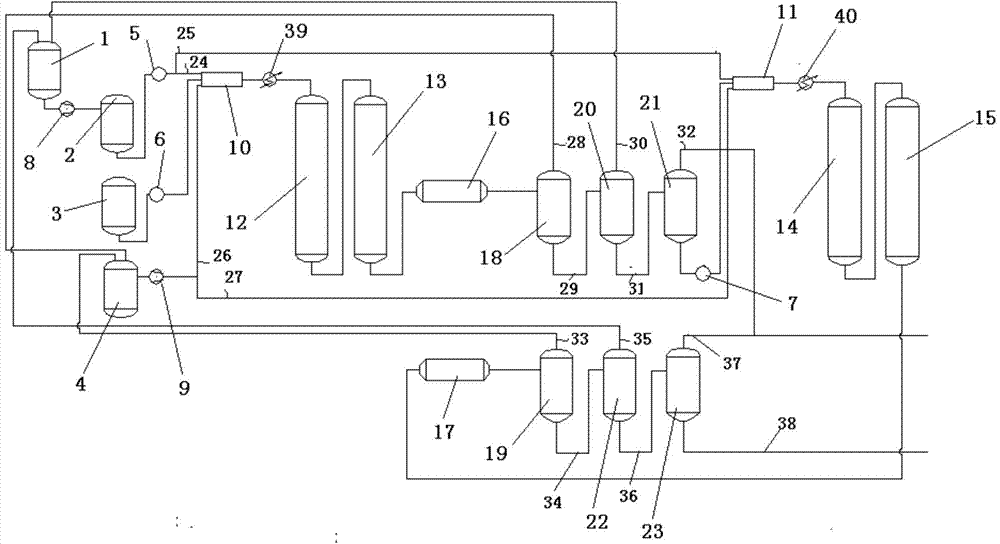

[0016] The present invention will be further described below in conjunction with the accompanying drawings.

[0017] like figure 1 As shown, taking a reaction device containing 4 reactors as an example, the polyether used is polypropylene glycol ether with an average molecular weight of 230.

[0018] The liquid ammonia in the second storage tank 2 passes through the pipeline 24 and the pipeline 25 after passing through the first feed pump 5, and the liquid ammonia ratio in the control pipeline 24 and the pipeline 25 is 1:1, and enters the first static mixer 10 and the second static mixer respectively. static mixer 11. The polyether in the third storage tank 3 enters the first static mixer 10 through the second feed pump 6 to be mixed with liquid ammonia, and the outlet pressures of the first feed pump 5 and the second feed pump 6 are all controlled to be 13.5MPa , The feed ratio is liquid ammonia: polyether is 4.5:1 (weight ratio). After the hydrogen in the fourth storage t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com