Novel pipe fitting cutting and chamfering machine

A technology of chamfering machine and cutting mechanism, which is applied in the direction of metal processing, etc., can solve the problems of complex structure, many flying chips, high noise, etc., and achieve the effect of less energy consumption, less failure rate, and no powder chips

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

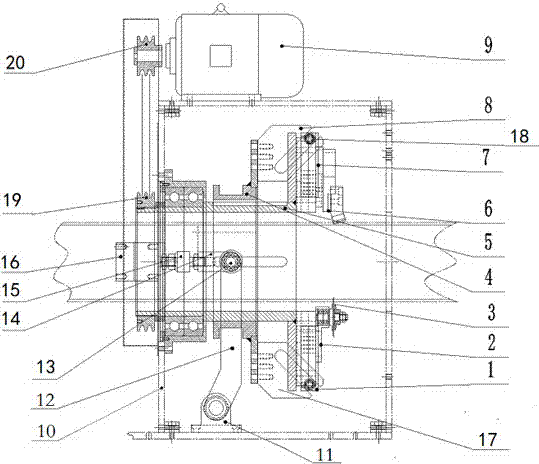

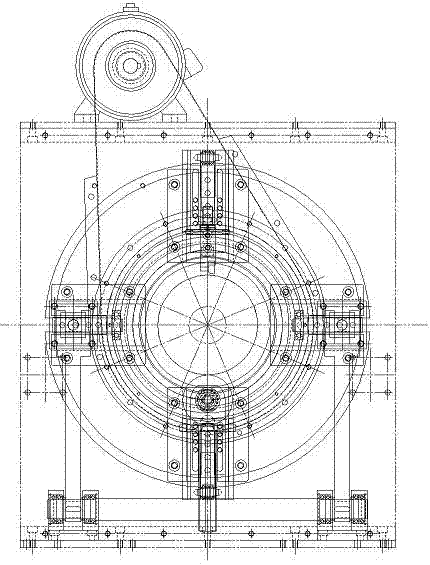

[0021] like figure 1 and figure 2 As shown, a novel pipe cutting and chamfering machine is used for cutting high-calcium pipes, including a frame 10, a rotating disk 5 arranged on the frame, a cutting mechanism, a clamping mechanism and a driving device, and the rotating disk 5 is formed by The driving device controls the rotation, and the cutting mechanism includes a rocker arm base 11 arranged on the frame 10, a rocker arm 12 connected with the rocker arm base 11, a pusher shaft 13 connected with the rocker arm 12, and a pusher shaft 13 connected with the rocker shaft 13. The pusher disc 4, the pusher shaft 13 is controlled to slide by the cylinder 16, specifically the cylinder 16 is connected with the pusher shaft 13 through the floating joint 15 and the cylinder joint 14 in turn, and the pusher disc 4 is provided with a push-up Knife arm and lower pusher arm, described upper and lower pusher arms are all provided with chute, and described upper pusher arm 8 is connected ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap