Low-frequency wideband nacreous layer bionic vibration isolation material

A nacre and broadband technology, applied in the field of vibration isolation materials, can solve the problems that the target bandwidth frequency cannot be designed, vibration cannot be covered, wider acoustic frequency range, low frequency vibration reduction effect is not significant, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

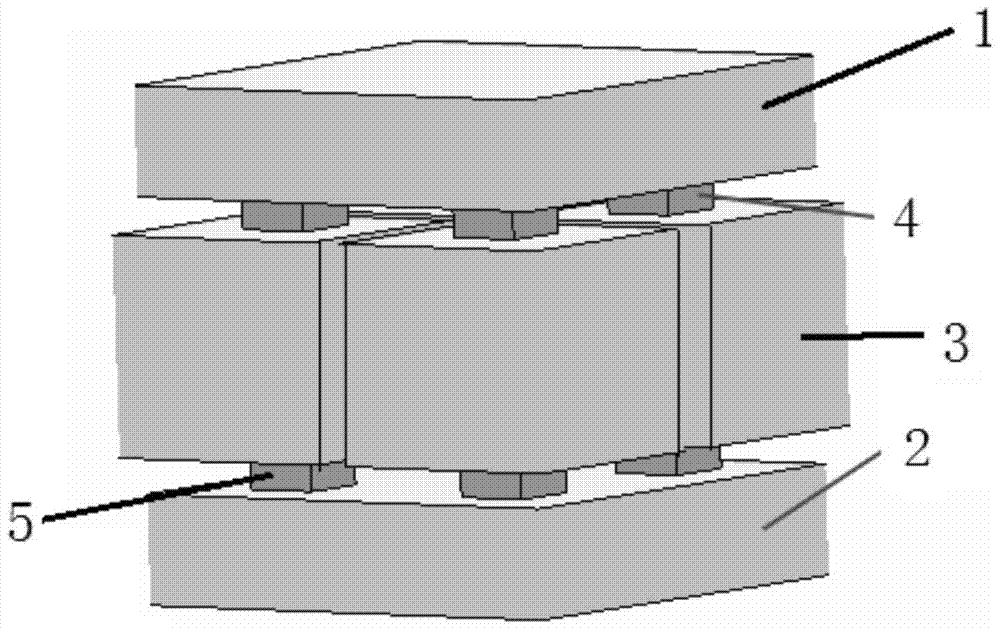

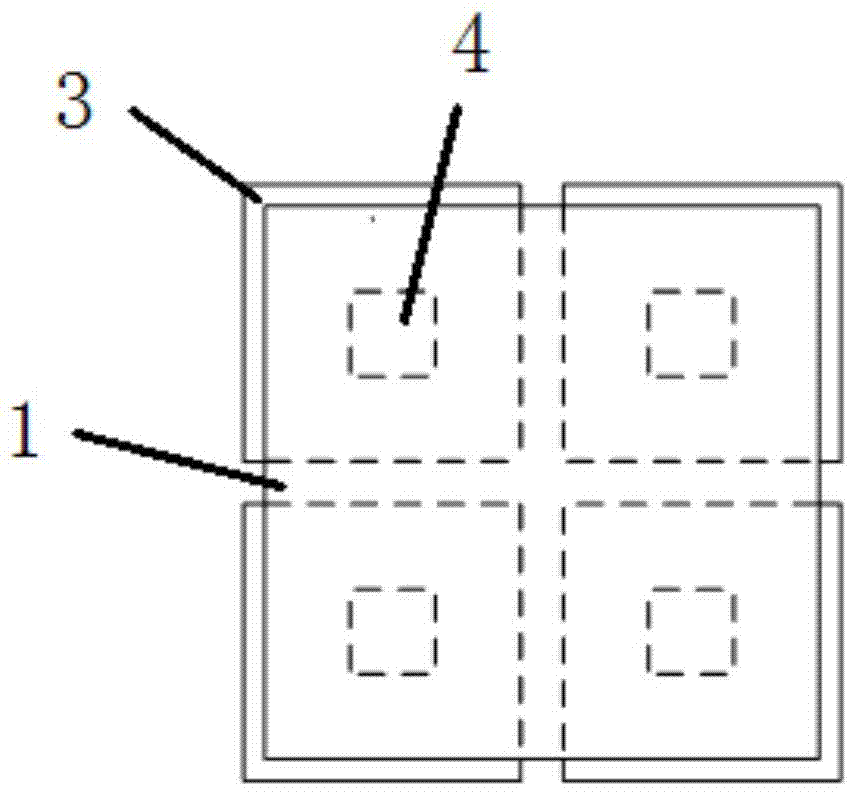

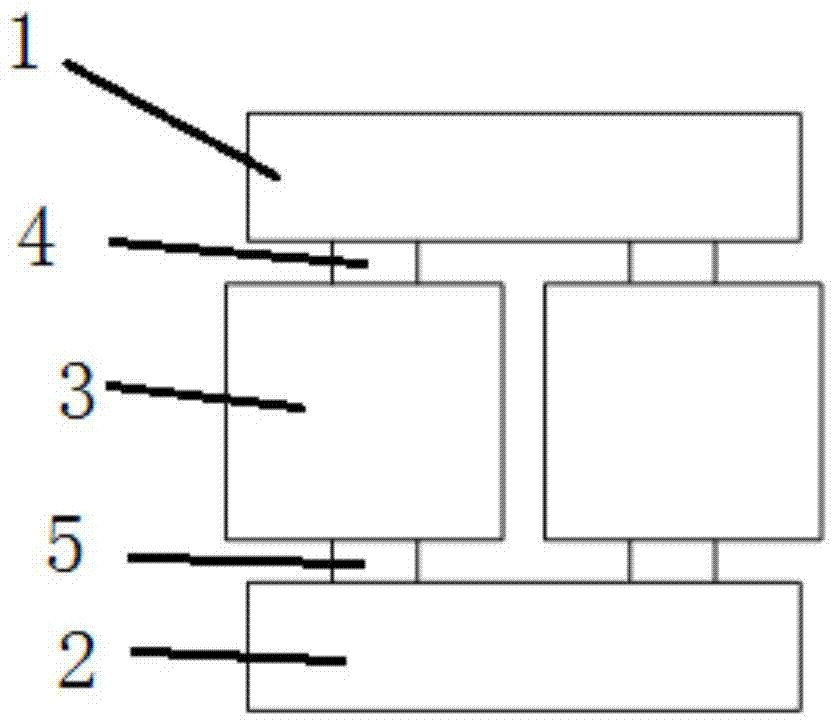

[0057] Such as figure 1 and figure 2 As shown, a low-frequency broadband nacre bionic vibration isolation material has a periodic structure, and the periodic structure is composed of a plurality of basic structural units;

[0058] The basic structural unit includes a structural layer one 1, a connecting layer and a structural layer two 2 sequentially connected along the height direction of the periodic structure;

[0059] The connection layer includes four secondary connection layers arranged in a 2×2 matrix, and the four secondary connection layers are arranged at equal intervals with a spacing of 5 mm;

[0060] The secondary connecting layer includes a structural layer three 3 and connecting layer one 4 and connecting layer two 5 respectively located on the upper and lower sides of the structural layer three 3, and the distance of 5mm refers to four structural layers three the spacing between 3;

[0061] The material of the structure layer one 1, the structure layer two ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com