Labeling quality detecting method and device

A quality detection method and technology to be detected, applied in the detection field, can solve the problems of false detection, low detection efficiency, and high false positive rate, and achieve the effects of improving detection efficiency, overcoming strong subjectivity, and improving detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

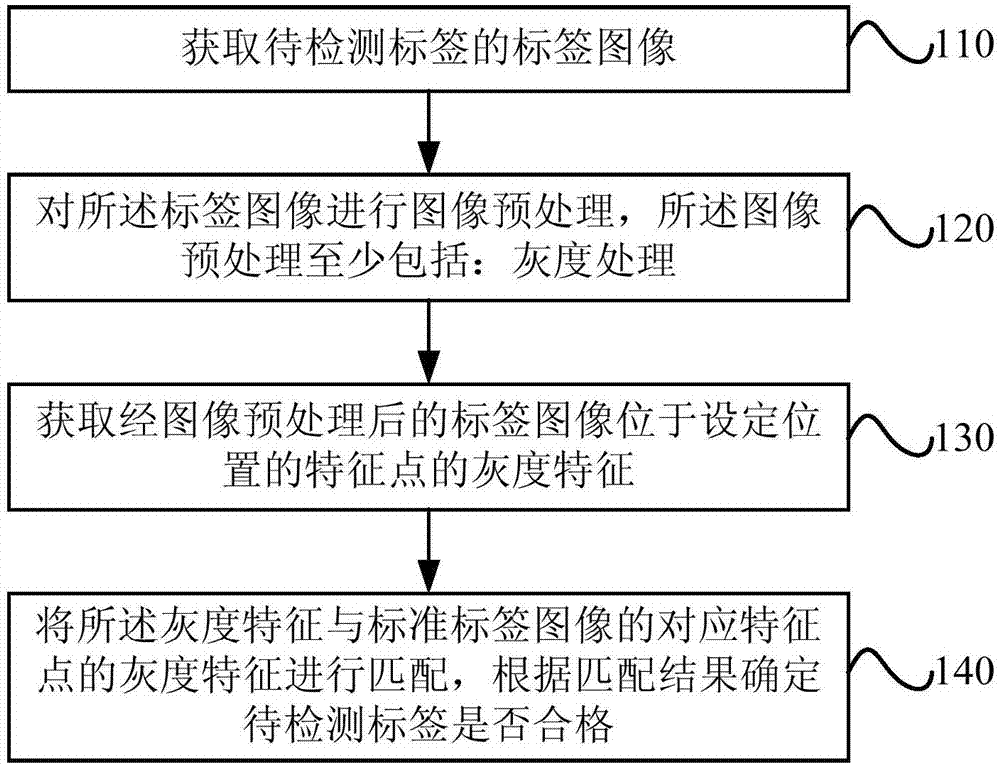

[0023] see figure 1 , is a flow chart of a labeling quality detection method provided in Embodiment 1 of the present invention. The method in the embodiment of the present invention can be executed by a labeling quality inspection device implemented by hardware and / or software, and the implementation device is typically configured in a server capable of image processing services.

[0024] Such as figure 1 As shown, the method includes:

[0025] Step 110, obtaining the label image of the label to be detected;

[0026] Specifically, in this step, the label image of the label to be detected at the exit of the labeling machine can be taken by the camera device. The imaging device preferably adopts a CCD (Charge-coupled Device, Charge-Coupled Device) camera, which has the advantages of high sensitivity, anti-glare, small distortion, small size, long life and anti-vibration.

[0027] Among them, the labeling machine is a device that sticks labels (paper or metal foil, etc.) on p...

Embodiment 2

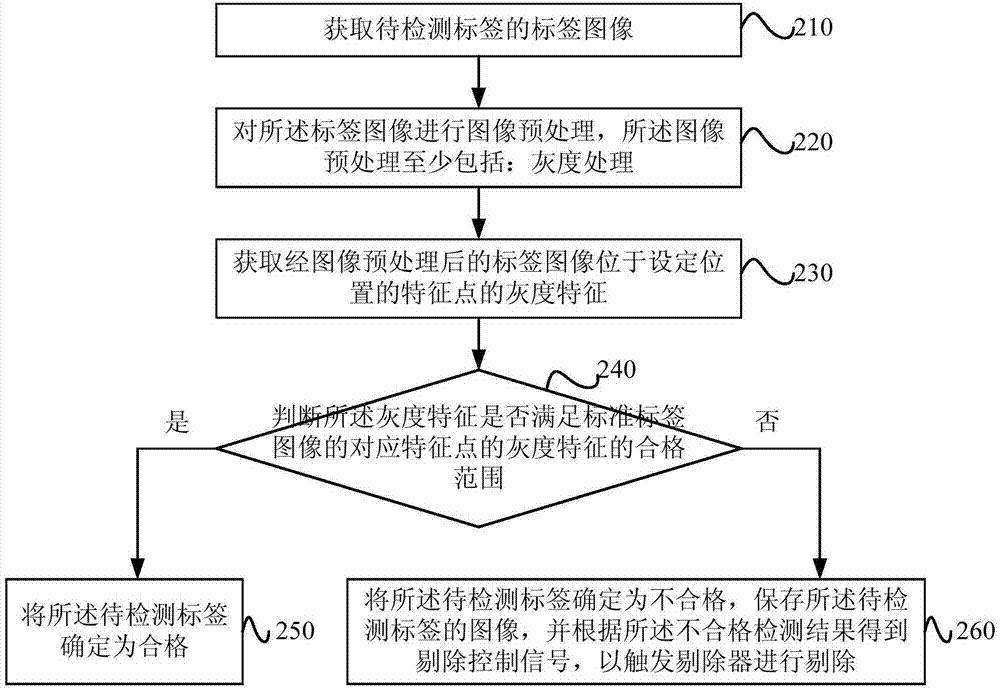

[0051] see figure 2 , is a flow chart of a labeling quality detection method provided in Embodiment 2 of the present invention. On the basis of the above-mentioned embodiments, this embodiment provides an optimal solution for matching the grayscale feature with the grayscale feature of the corresponding feature point of the standard label image, and determining whether the label to be detected is qualified according to the matching result. The method includes:

[0052] Step 210, acquiring the label image of the label to be detected;

[0053] Step 220, perform image preprocessing on the label image, the image preprocessing at least includes: grayscale processing;

[0054] Step 230, acquiring the grayscale feature of the feature point of the pre-processed label image at the set position;

[0055] Step 240, judging whether the grayscale feature satisfies the qualified range of the grayscale feature of the corresponding feature point of the standard label image, if yes, execut...

Embodiment 3

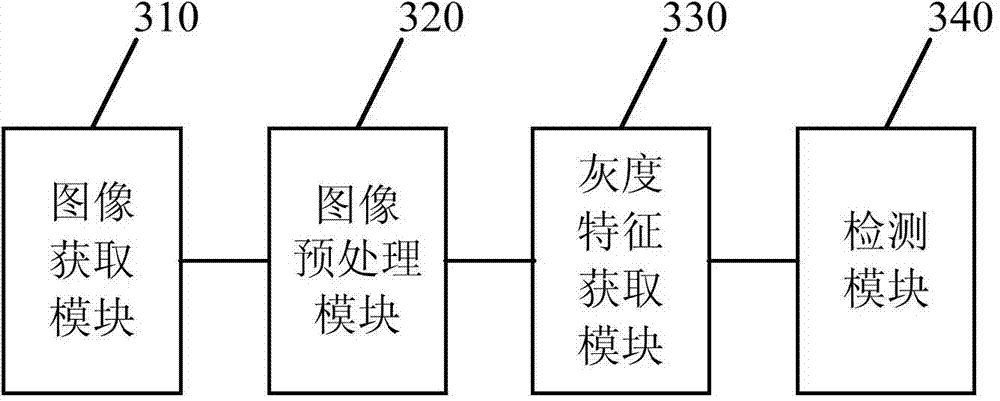

[0064] see image 3 , is a schematic structural diagram of a labeling quality detection device provided in Embodiment 3 of the present invention. The device includes: an image acquisition module 310 , an image preprocessing module 320 , a grayscale feature acquisition module 330 and a detection module 340 .

[0065] Wherein, the image acquisition module 310 is used to obtain the label image of the label to be detected; the image preprocessing module 320 is used to perform image preprocessing on the label image, and the image preprocessing includes at least: grayscale processing; grayscale feature acquisition module 330 is used to obtain the grayscale feature of the feature point at the set position of the label image after image preprocessing; the detection module 340 is used to match the grayscale feature with the grayscale feature of the corresponding feature point of the standard label image, Determine whether the label to be detected is qualified according to the matching...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com