Parallel-polarity double-magnet electronically-controlled permanent magnetic chuck

An electronically controlled permanent magnet and magnet technology, applied in the direction of load hanging components, transportation and packaging, etc., can solve the problems of small magnetic energy product of the sucker, complex magnetic circuit structure, thick overall thickness of the sucker, etc., to ensure the magnetic force and solve the overall problem Thickness and magnetic circuit structure are complex and the effect of volume reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention is described below in conjunction with accompanying drawing.

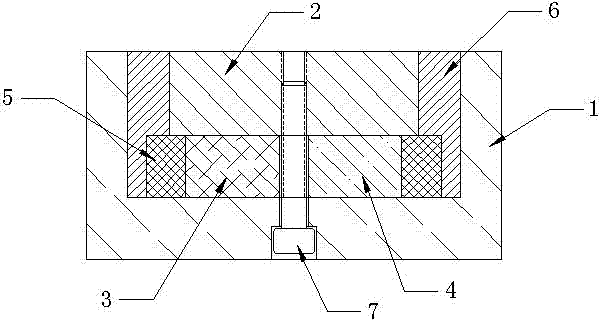

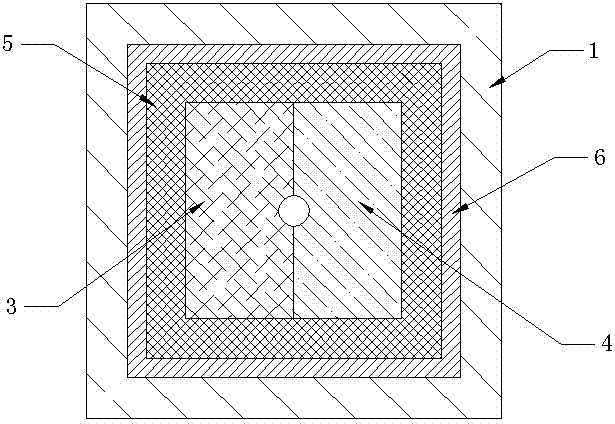

[0018] as attached Figure 1-2 As shown, a pole-to-parallel double-magnet electronically controlled permanent magnet chuck described in the present invention includes a housing 1, a magnetic pole piece 2, a reversible magnetic steel 3, an irreversible magnetic steel 4, an excitation coil 5 and an isolation layer 6; The reversible magnet 3 is an AlNiCo magnet, and the irreversible magnet 4 is a NdFeB magnet; the reversible magnet 3 and the irreversible magnet 4 are arranged in the housing 1, and the reversible magnet 3 and the irreversible magnet 4 are in the The body 1 is symmetrical along the center line of the housing 1; the magnetic pole piece 2 is arranged on the upper side of the reversible magnetic steel 3 and the irreversible magnetic steel 4, and the magnetic pole piece 2, the reversible magnetic steel 3 and the irreversible magnetic steel 4 are fastened by bolts 7 fixed; the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com