Pout detection method and device for steel pipe weld seam

A detection method and detection device technology, applied in the direction of measuring devices, instruments, etc., can solve the problems of low accuracy of the measurement results of the pout and the deviation of the measurement base surface, and achieve the purpose of solving the deviation of the measurement base surface and improving the accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

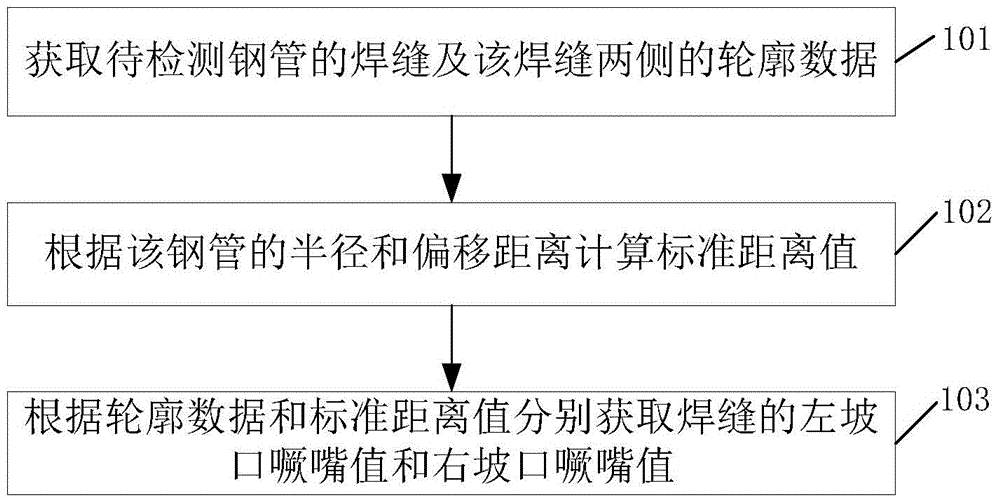

[0050] Such as figure 1As shown, the present embodiment provides a method for detecting the pout of a steel pipe weld, including:

[0051] Step 101, acquiring the weld seam of the steel pipe to be detected and the contour data of both sides of the weld seam.

[0052] In this embodiment, the profile data in step 101 may be obtained by a laser sensor such as a laser two-dimensional scanning sensor, or may be obtained by other methods, which will not be described here.

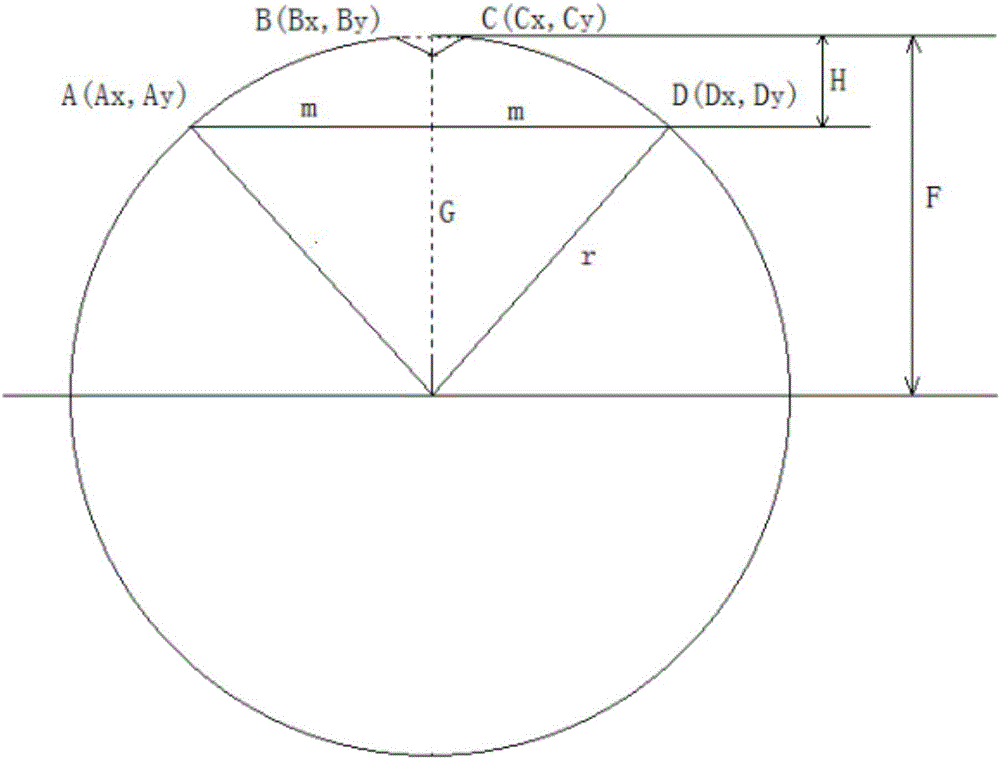

[0053] Step 102, calculating a standard distance value according to the radius and offset distance of the steel pipe.

[0054] In this embodiment, both the radius and the offset distance in step 102 are preset. Wherein, the radius of the steel pipe in step 102 is the standard circle radius of the steel pipe.

[0055] In this embodiment, step 102 may calculate the standard distance value in the following manner, or other methods may be used to calculate the standard distance value, which is not limited here.

...

Embodiment 2

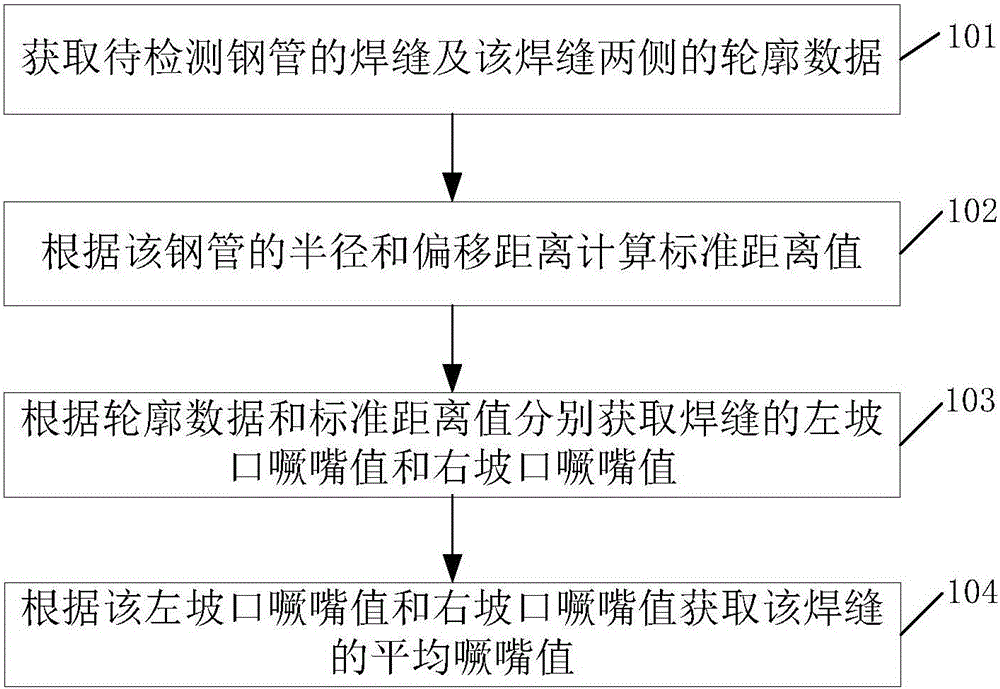

[0067] Such as image 3 As shown, the pout detection method of the steel pipe weld seam that the embodiment of the present invention provides, this method and figure 1 Similar as shown, except that it also includes:

[0068] Step 104, obtaining the average pout value of the weld according to the left groove pout value and the right groove pout value.

[0069] In this embodiment, the average pout value in step 104 may be the average value of the left-groove pout value and the right-groove pout value.

[0070] In this embodiment, after the average pout value is obtained through step 104, it can be determined whether the weld pout is inside or outside according to the relationship between the average pout value and the standard distance value. The calculation of the average pout value can be more accurate than the calculation of the pout of the steel pipe weld by the pout value of the groove on one side alone.

[0071] The invention has the following beneficial effects: the po...

Embodiment 3

[0073] Such as Figure 4 As shown, the pout detection method of the steel pipe weld seam that the embodiment of the present invention provides, this method and figure 1 Similar as shown, except that it also includes:

[0074] Step 105, within a preset distance interval, update the offset distance.

[0075] In this embodiment, the preset distance interval in step 105 can be optional. Preferably, it may be 50 to 100 mm.

[0076] In this embodiment, after the offset distance is updated, step 102 and step 103 can be executed again to obtain the left groove pout value and the right groove pout value corresponding to the updated offset distance. The above process can be repeated only once; in order to improve the accuracy of the measurement results, the process of updating the offset distance and calculating the left and right bevel pout values can also be repeated for a preset number of times.

[0077] In step 106, the final beak value of the steel pipe weld is obtained accor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com