Silicon pressure sensor temperature compensation method based on extreme learning machine

An extreme learning machine and pressure sensor technology, applied in the direction of measuring fluid pressure, instruments, measuring devices, etc., can solve the problems that the compensation accuracy cannot meet the high precision requirements, it is difficult to meet the high precision, and the network training time is long.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

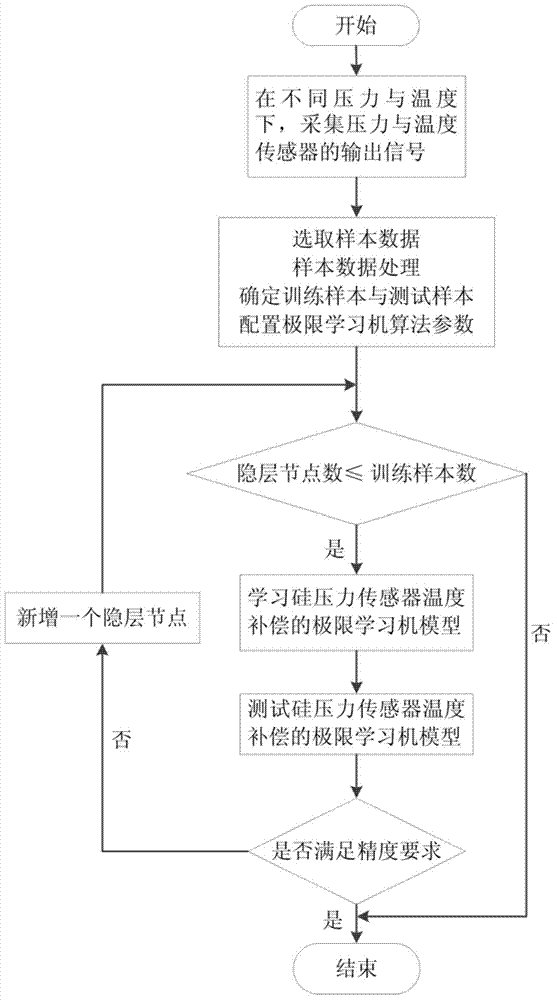

[0026] The implementation of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0027] refer to figure 1 , a silicon pressure sensor temperature compensation method based on extreme learning machine, comprising the following steps:

[0028] Step 1: Collect a set of pressure values P (within the measuring range of the pressure sensor) applied by the pressure sensor at different temperatures (within the working temperature range), such as [-40°C, -30°C,...,80°C], such as [0MPa ,2MPa,...,20MPa], output pressure signal V, temperature sensor output signal T and measured pressure P, and form a data source [V T P];

[0029] Step 2: Select data sources under different temperature and pressure conditions as sample data, and select samples according to the principle of equal intervals, for example, the temperature interval is 20°C, the pressure interval is 5MPa, and the pressure; for each column of the sample data, use Perform n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com