Method for rapidly detecting corrosion resistance of grid of lead-acid storage battery

A lead-acid battery, rapid measurement technology, used in weather resistance/light resistance/corrosion resistance, measuring device, weighing by removing certain components, etc., can solve the problems of long time, complicated operation, etc. Simple and convenient for real-time measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

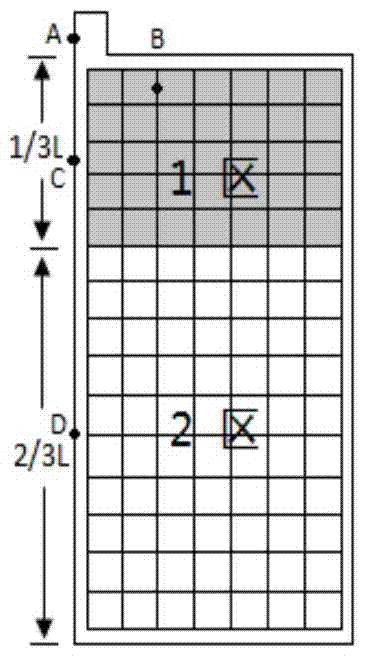

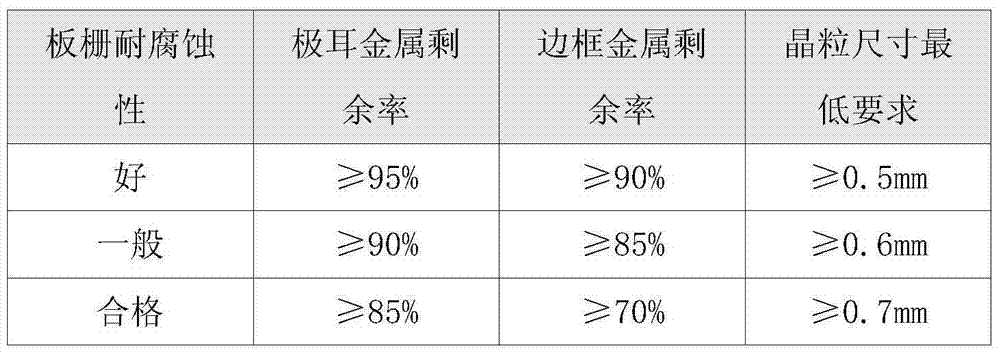

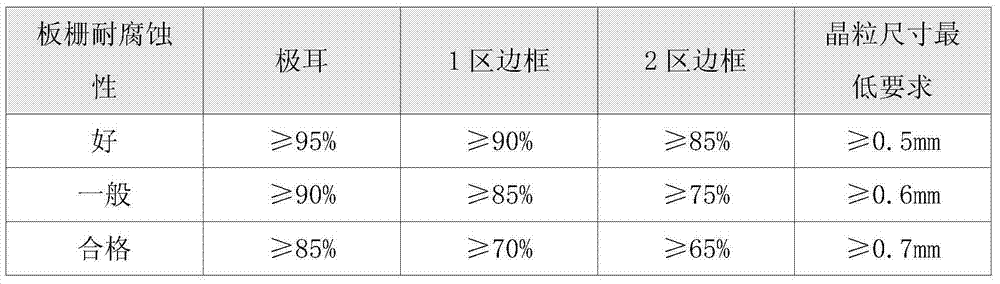

[0054] 1. Acid etching test: Cut about 3cm sample from the side frame of the 85A positive grid (for grain test), measure the thickness of the grid lug (point A), the thickness of the main rib (point B), and the frame of zone 1 Thickness (point C), the thickness of the border of zone 2 (point D), and then put it into the acid etching tank filled with 1500mL glacial acetic acid and 500mL 30% hydrogen peroxide, start timing, take out the grid in about 3 minutes, wash it with water, and measure B Point thickness, if the thickness of point B is reduced to 12±1%, measure the data of other 3 points, if the thickness reduction of point B does not meet the requirements, continue acid etching until the thickness of point B is reduced to 12±1%, then measure points A and C , The thickness of point D, and calculate the metal remaining rate before and after acid etching. The remaining rate of point A is 96%, the remaining rate of point C is 92%, and the remaining rate of point D is 90%, and...

Embodiment 2

[0061] 1. Acid etching test: Cut about 3cm sample from the side frame of the 72A positive grid (for grain test), measure the thickness of the grid lug (point A), the thickness of the main rib (point B), and the frame of zone 1 Thickness (point C), the thickness of the border of zone 2 (point D), then put it into the acid etching tank filled with 1000mL glacial acetic acid and 500mL 30% hydrogen peroxide, start timing, take out the grid in about 2 minutes, wash it with water, and measure B Point thickness, if the thickness of point B is reduced by 12±1%, measure the data of other 3 points, if the thickness of point B does not meet the requirements, continue acid etching until the thickness of point B is reduced by 12±1%, then measure point A, point C, point D Point thickness, and calculate the metal remaining rate before and after acid etching. The remaining rate of point A is 92%, the remaining rate of point C is 89%, and the remaining rate of point D is 85%, and there is no b...

Embodiment 3

[0068] 1. Acid etching test: cut a 3cm sample from the side frame of the 100A positive grid (for grain test), measure the thickness of the grid lug (point A), the thickness of the main rib (point B), and the thickness of the frame of zone 1 (point C), the thickness of the frame in zone 2 (point D), and then put it into an acid etching tank filled with 1600mL glacial acetic acid and 400mL 30% hydrogen peroxide, start timing, take out the grid in about 4 minutes, wash it with water, and measure point B Thickness, if the thickness of point B is reduced by 12±1%, measure the data of other 3 points, if the thickness of point B is not reduced to meet the requirements, continue acid etching until the thickness of point B is reduced by 12±1%, then measure points A, C and D thickness, and calculate the metal remaining rate before and after acid etching. The remaining rate of point A is 90%, the remaining rate of point C is 87%, and the remaining rate of point D is 83%, and there is no ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average diameter | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com