Device and method for positioning wheel hub work piece

A hub and workpiece technology, applied in the field of workpiece positioning, can solve problems such as difficult hub positioning and large positioning deviation of hub workpieces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

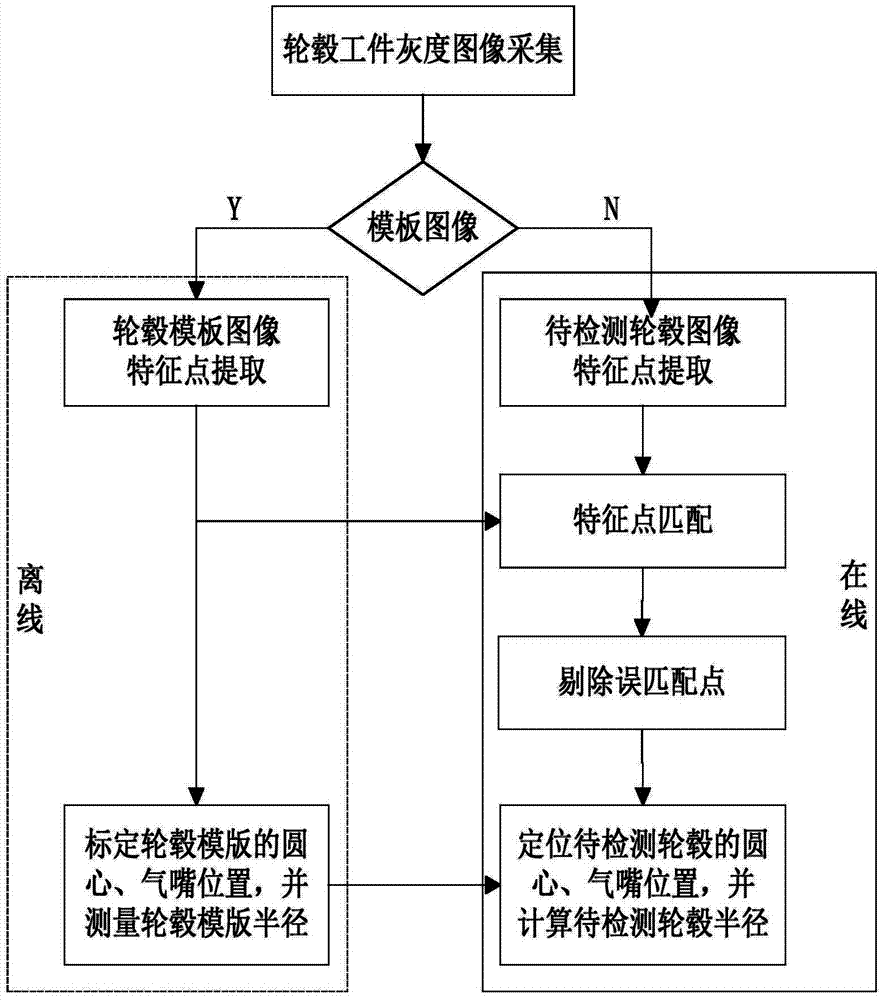

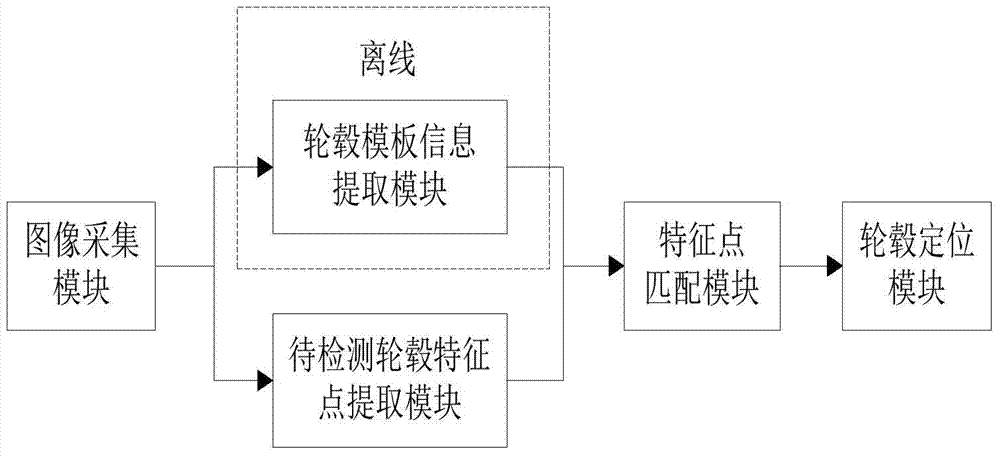

[0115] The present invention will be further described below in conjunction with the accompanying drawings. The composition of a device for hub workpiece positioning is as follows: figure 2 As shown, the specific method flow is as follows figure 1 shown.

[0116] In order to verify the effectiveness of the present invention, objective tests and subjective tests were carried out.

[0117] 1. Subjective performance test (visual effect)

[0118] When the camera captures the image of the wheel hub, there will be different noise interference situations. In order to verify the effectiveness of the method of the present invention, several images under different interference conditions were collected for experiments.

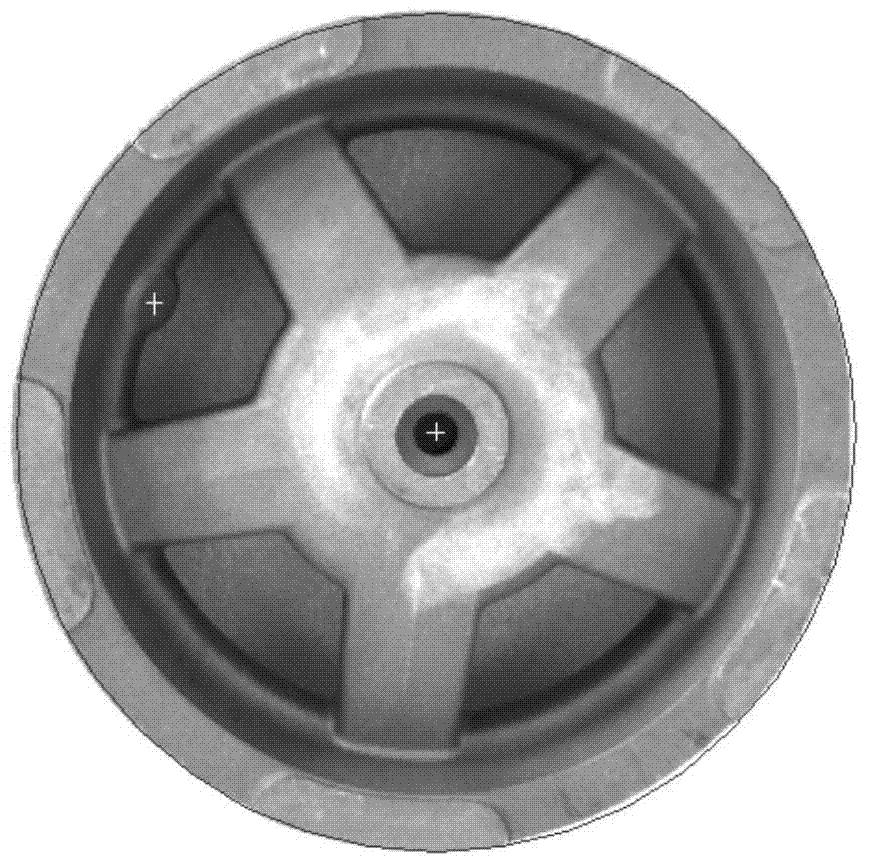

[0119] In the experiment, the size of the template image is 690×691 pixels, and the size of the detection image is 1280×960 pixels. The wheel hub template and its marking points are as follows: image 3 shown. exist image 3 In , the center of the hub template ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com