Test method for welding CCT (continuous cooling transformation) diagram of resistance type thermal simulation test machine

A test method and thermal simulation technology, which is applied in the field of physical simulation test, can solve the problems of low proximity, the test process does not consider the change of heating speed, and it is difficult to accurately find out the phase transition point, so as to achieve the effect of accurate phase transition point

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A test method for welding CCT chart of a resistance thermal simulation testing machine, the steps of which are as follows:

[0037] 1) Heat the thermal simulation sample from room temperature to the peak temperature Tp 1300°C, cooling time t 8 / 5 If it is set to 3s, the heating rate is set to 700°C / s;

[0038] Since the heating speed is set to be greater than 200°C / s, therefore:

[0039] When heating from room temperature to 1000°C, heat according to the set heating rate of 700°C / s, and then heat to the peak temperature Tp1300°C according to the heating rate of 100°C / s;

[0040] 2) After heating, stay for 1 second;

[0041] 3) Since the cooling time is set to t 8 / 5 =3s, so it is directly cooled from 1300°C to room temperature at a rate of 100°C / s;

[0042] 4) According to the tangent method, the phase transition temperature accurately found on the thermal expansion curve starts at 460°C and ends at 310°C.

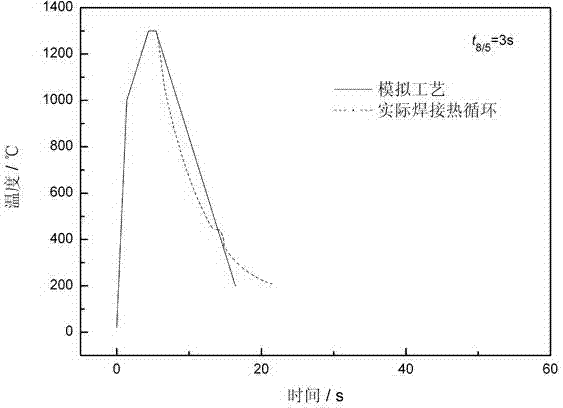

[0043] The comparison between the above simulation proces...

Embodiment 2

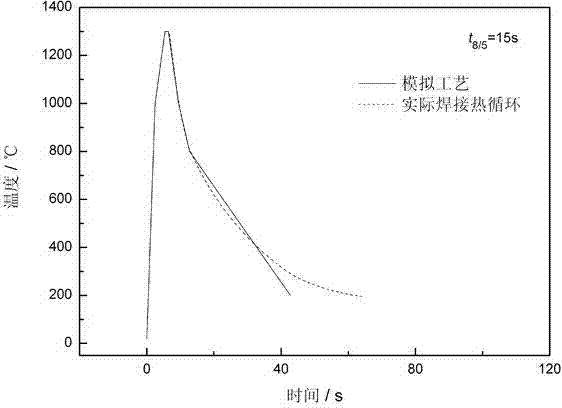

[0045] 1) Heat the thermal simulation sample from room temperature to the peak temperature Tp1300℃, cooling time t 8 / 5 When 15s is selected, the heating rate is set to 400°C / s;

[0046] Since the heating rate is set to be greater than 200°C / s, therefore:

[0047] When heating from room temperature to 1000°C, heat according to the set heating rate of 400°C / s, and then heat to the peak temperature Tp1300°C according to the heating rate of 100°C / s;

[0048] 2) After heating, stay for 1 second;

[0049] 3) Linearly cool the sample in three stages:

[0050] A. Division of stages: cooling from peak temperature Tp1300°C to 1000°C is the first cooling stage; cooling from 1000°C to 800°C is the second cooling stage; cooling from 800°C to room temperature is the third cooling stage;

[0051] B. The cooling rate of each cooling stage is determined according to the following cooling time: cooling rate ν 1 Indicates the first cooling rate, ν 2 Indicates the second cooling rate, ν 3 In...

Embodiment 3

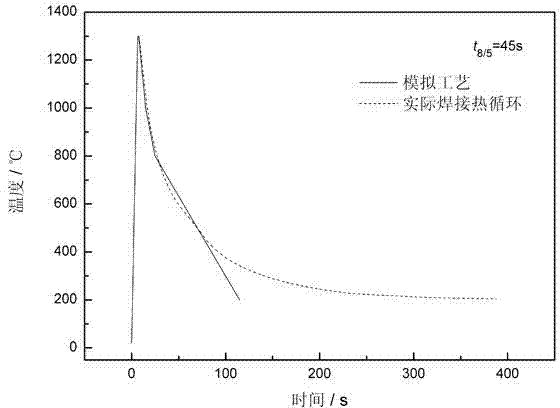

[0056] 1) Heat the thermal simulation sample from room temperature to the peak temperature Tp1300℃, cooling time t 8 / 5 If it is set to 45s, then the heating rate is set to 200°C / s, that is, the sample is directly heated to the peak temperature Tp1300°C at a heating rate of 200°C / s;

[0057] 2) After heating, stay for 1 second;

[0058] 3) Linearly cool the sample in three stages:

[0059] A. Division of stages: cooling from peak temperature Tp1300°C to 1000°C is the first cooling stage; cooling from 1000°C to 800°C is the second cooling stage; cooling from 800°C to room temperature is the third cooling stage;

[0060] B. The cooling rate of each cooling stage is determined according to the following cooling time: cooling rate ν 1 Indicates the first cooling rate, ν 2 Indicates the second cooling rate, ν 3 Indicates the third cooling rate;

[0061] due to cooldown t 8 / 5 Set to 45s, ν 1 then cooling at 40°C / s, ν 2 Cooling at 20°C / s; ν 3 Cool to room temperature accord...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com