Anti-stab uniform for police and production method thereof

A stab-proof clothing and police technology, applied in clothing, clothing, applications, etc., can solve the problems of complex production process and long labor time, and achieve simple production process, less use of rivets, and good wearing comfort and flexibility. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

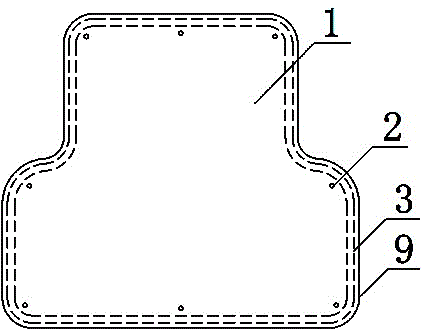

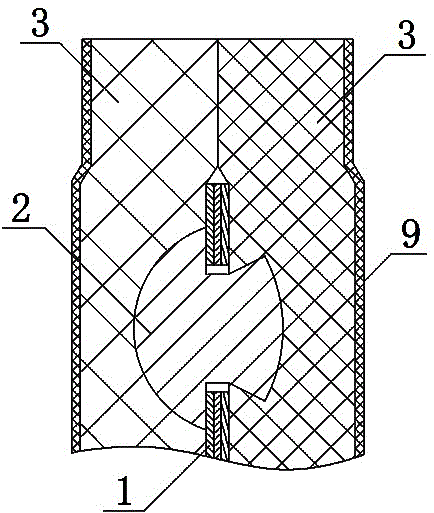

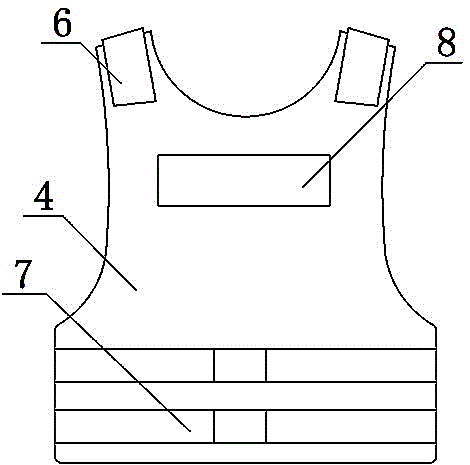

[0030] Police stab-resistant clothing, which includes a stab-resistant layer and a jacket; such as figure 1 with figure 2 As shown, the stab-proof layer includes a chip 1, a buffer layer 3 and a protective cover 9. The chip 1 is a "convex"-shaped structure with an arc-shaped cross section. Multiple chips 1 are aligned and overlapped, and riveted into one body by rivets 2. , two buffer layers 3 are coated on both sides of the chip 1 respectively, and the edges of the two buffer layers 3 are bonded and sealed, the buffer layer 3 is EVA foam, and the protective cover 9 completely covers the chip 1 covered with the buffer layer 3 Covering, and the edges are bonded and sealed, the protective sleeve 9 is covered on both sides of the anti-stab chip, and the edges are heat-pressed and bonded, and the protective sleeve is black, opaque, and hydrostatic pressure ≥ 18kPa laminated fabric; image 3 with Figure 4 As shown, the overcoat includes a front panel 4, a rear panel 5, a should...

Embodiment 2

[0042] Its structure is with embodiment 1.

[0043] The making method of police stab-proof clothing comprises the following steps:

[0044]S1. Material selection: Select hard stainless steel coils with a width of 420mm and a thickness of 0.25mm and 0.40mm, and deburr them;

[0045] S2, blanking: put the hard stainless steel plate selected in step S1 on the punching table, press blanking according to the drawing, and punch out the rivet hole inside the male corner to obtain the chip 1;

[0046] S3, rounding: the chip 1 obtained in step S2 is rounded on a rounding machine, so that the cross section of the chip 1 has an arc-shaped structure;

[0047] S4. Riveting: Align multiple chips 1 and overlap them together. After overlapping, the total thickness is 0.65mm. Specifically, one layer of 0.25mm and one layer of 0.4mm chips 1 are overlapped, and the rivets 2 are passed through the rivet holes in turn. riveting multiple chips 1 together;

[0048] S5. Bonding: according to the s...

Embodiment 3

[0052] Its structure is with embodiment 1.

[0053] The making method of police stab-proof clothing comprises the following steps:

[0054] S1. Material selection: select a hard stainless steel coil with a width of 430mm and a thickness of 0.40mm, and remove the burrs;

[0055] S2, blanking: place the hard stainless steel plate selected in step S1 on the workbench of the laser cutting machine, cut and blank the material according to the drawing, and cut rivet holes on the inner side of the male corner to obtain chip 1;

[0056] S3, rounding: the chip 1 obtained in step S2 is rounded on a rounding machine, so that the cross section of the chip 1 has an arc-shaped structure;

[0057] S4. Riveting: Align multiple chips 1 and overlap them together. After overlapping, the total thickness is 0.80 mm. Specifically, two chips 1 of 0.40 mm overlap each other. Pass the rivets 2 through the rivet holes in turn, and place the multiple chips 1 riveted together;

[0058] S5. Bonding: acc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com