Ornidazole injection liquid

A technology of ornidazole injection and ornidazole, which is applied in the directions of drug delivery, antibacterial drugs, organic active ingredients, etc., can solve the problems of excessive insoluble particles and poor storage stability, and achieves less irritation and improved storage stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

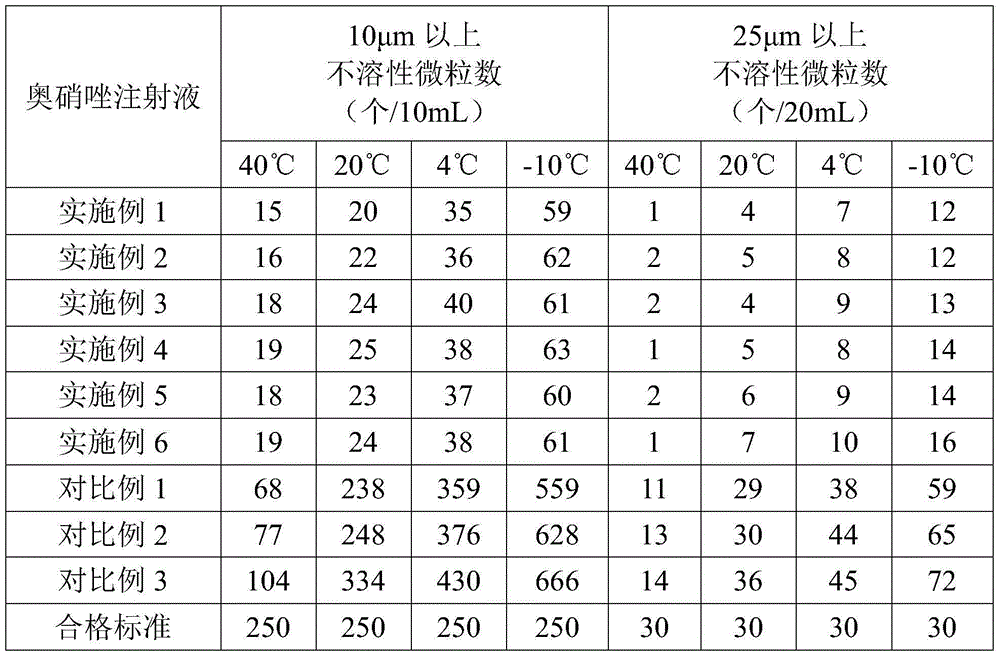

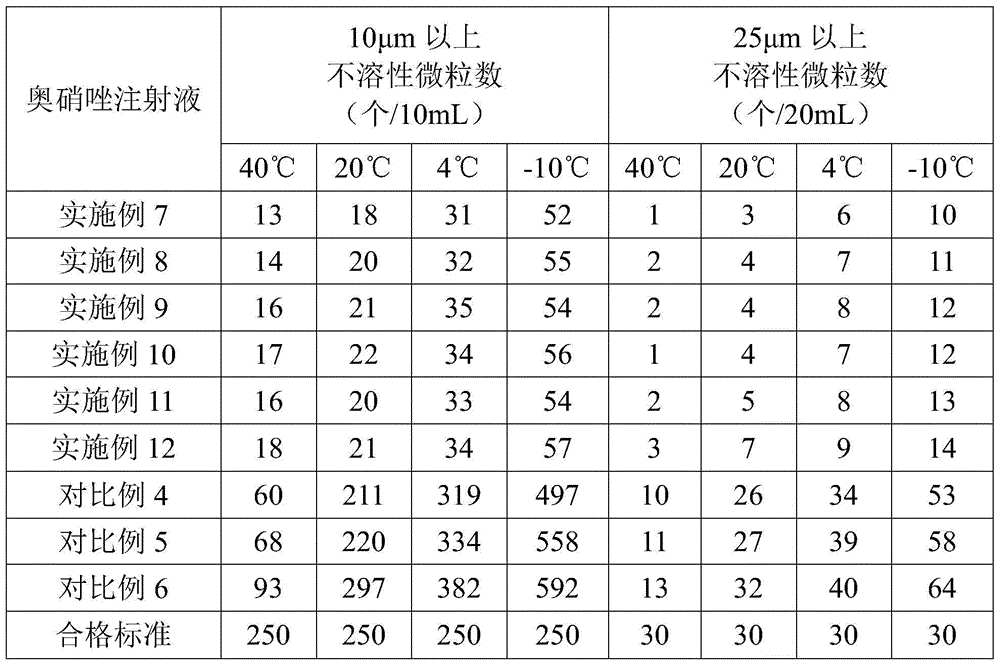

Examples

preparation example Construction

[0013] The invention provides a preparation method of ornidazole injection, the preparation method comprising: (1) uniformly mixing ornidazole and an organic solvent; wherein, the organic solvent is ethanol, or the organic solvent is ethanol and A mixture of propylene glycol; (2) subjecting the homogeneously mixed material to at least two heating and cooling cycles; wherein, the heating and cooling cycles include: first heating from a temperature of 10-30°C to a temperature of 40-60°C, and then from 40 A temperature of -60°C is cooled to a temperature of 10-30°C.

[0014] Wherein, ornidazole refers to a substance whose chemical name is 1-(3-chloro-2-hydroxypropyl)-2-methyl-5-nitroimidazole.

[0015] Wherein, when the organic solvent is ethanol, the amount of ornidazole and ethanol can be the conventional amount in the field of preparation of ornidazole injection, for example, relative to 1g of ornidazole, the amount of ethanol can be 3.5- 5.5 mL; preferably, relative to 1 g o...

Embodiment 1

[0026] Mix 1 g of ornidazole and 4.5 mL of ethanol uniformly, and the temperature of the uniformly mixed material is 20° C. The uniformly mixed material was heated to 50°C in 15 minutes, maintained at 50°C for 300s, and then cooled to 20°C in 15 minutes to complete the first heating and cooling cycle. The material that completed the first heating and cooling cycle was heated to 50°C in 15 minutes, maintained at 50°C for 300s, and then cooled to 20°C in 15 minutes to complete the second heating and cooling cycle.

[0027] The ornidazole injection of this example was prepared by filtering and sterilizing the material after two heating and cooling cycles with a filter membrane with a pore size of 0.22 μm.

Embodiment 2

[0029] Mix 1 g of ornidazole with 4 mL of ethanol uniformly, and the temperature of the uniformly mixed material is 15° C. The uniformly mixed material was heated to 45°C for 10 minutes, maintained at 45°C for 600s, and then cooled to 11°C for 10 minutes to complete the first heating and cooling cycle. The material that completed the first heating and cooling cycle was heated to 45°C in 10 minutes, maintained at 45°C for 480s, and then cooled to 28°C in 10 minutes to complete the second heating and cooling cycle.

[0030] The ornidazole injection of this example was prepared by filtering and sterilizing the material after two heating and cooling cycles with a filter membrane with a pore size of 0.22 μm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com