Backwash laminated filter

A laminated filter and backwashing technology, applied in the direction of fixed filter elements, filtration separation, chemical instruments and methods, etc., can solve the problems of secondary pollution of springs, secondary pollution, high requirements for sealing, etc. , to achieve stable mobile connection, prevent secondary pollution, and ensure the effect of filtering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

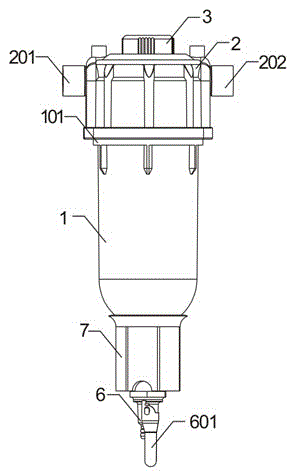

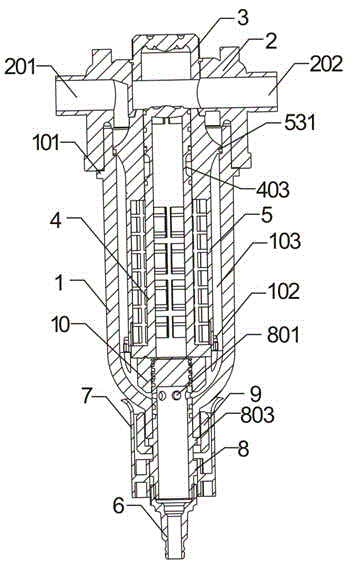

[0049] The title of each reference sign in the accompanying drawings of the present invention is:

[0050] Housing 1, limit piece 101, clip 102, cavity 103, valve body 2, water inlet 201, water outlet 202, through hole 203, plugging piece 3, filter stack 4, water outlet frame 401, water outlet hole 411, base 402, protrusion 421, concave block 422, concave surface 403, filter element stack 5, card slot 501, chute 502, water inlet frame 503, seal ring 531, first water inlet hole 532, second water inlet Hole 533, drain valve 6, drain valve upper port 611, suspension part 621, drain valve lower port 612, handle 601, rotating cylinder 7, rotating hole 701, drain pipe 8, inlet port 801, drain hole 811, external thread 812, The outlet port 802 , the rotating part 821 , the clip 803 , the eccentric nut 9 , the nut 10 , the block 111 , and the internal thread 112 .

[0051] Describe the present invention in further detail below in conjunction with accompanying drawing:

[0052] Such ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com