Two-stage bouncing camellia oleifera seed shell sorting machine

A technology of camellia fruit and sorting machine, which is applied in the directions of grading, shelling, solid separation, etc., can solve the problems of unsatisfactory sorting effect, inability to separate shell and seeds, complex sorting tank structure, etc., so as to improve the sorting capacity and effect, the effect of improving the sorting effect, and the effect of speeding up the scrolling motion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

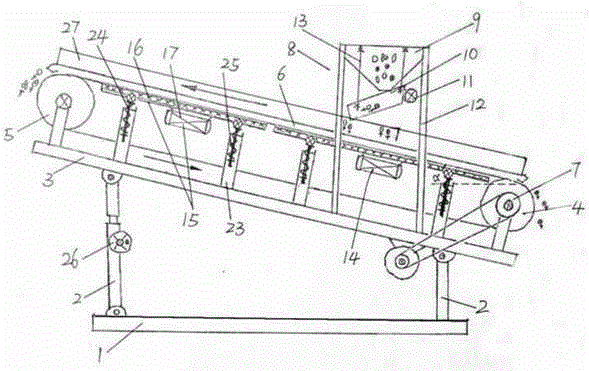

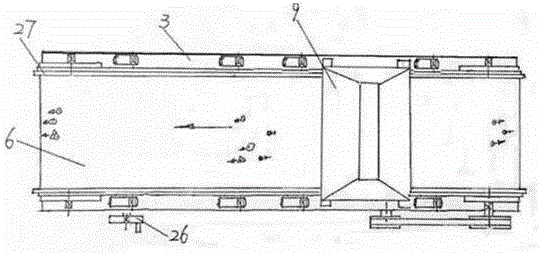

[0027] The present embodiment comprises frame 1, conveyer belt device, dispersed feeding device, secondary bounce device, and described frame comprises base and some main pillars 2 that are fixedly connected thereon, and main frame 3 is fixed on the main pillar, wherein The height of the main pillar on one side is adjustable; the conveyor belt device is arranged on the main frame 3, including the driving roller 4, the driven roller 5 and the sorting conveyor belt 6 tensionedly installed on the two rollers, the sorting conveyor belt The working surface of 6 is at an inclined angle to the horizontal plane, and the working surface movement mode of the sorting conveyor belt is from the lower end to the higher end. The driving roller 4 is connected with the motor and the transmission through the pulley 7, and the working of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com