A kind of composite material zinc ingot mold and preparation method thereof

A composite material and zinc ingot mold technology, which is applied in the field of composite materials, can solve the problem of no improvement in the service life of the zinc ingot mold, and achieve the effects of excellent wear performance, good zinc liquid corrosion resistance, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

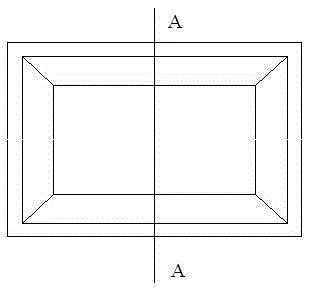

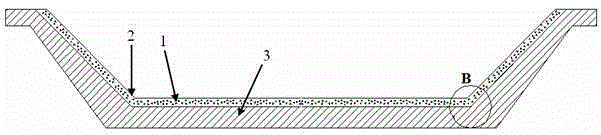

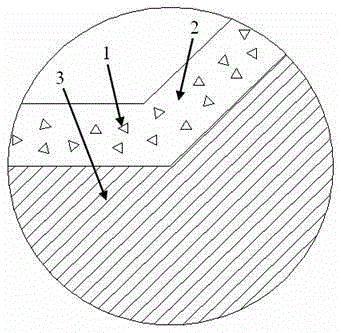

[0026] Such as Figures 1 to 3 As shown, the composite material zinc ingot mold, the composite material zinc ingot mold is covered with layered ceramic particle reinforced metal matrix composite material on the surface of the existing zinc ingot mold, the thickness of the ceramic particle reinforced metal matrix composite material is 4mm, ceramic The particle size is 80 mesh, and the volume of ceramic particles in the ceramic particle reinforced metal matrix composite material accounts for 52%, and the remaining volume is the same metal matrix as the existing zinc ingot mold metal material; wherein the ceramic particles are B 4 C, the metal base is cast steel (specifically 40Cr steel).

[0027] The preparation method of this above-mentioned composite material zinc ingot mould, its concrete steps are as follows:

[0028] Step 1: Mix the ceramic particles and the binder in a ball mill for 30 minutes and then sieve them, and press them into a triangular preform under a pressure ...

Embodiment 2

[0033] Such as Figures 1 to 3 As shown, the composite material zinc ingot mold, the composite material zinc ingot mold is covered with layered ceramic particle reinforced metal matrix composite material on the surface of the existing zinc ingot mold, the thickness of the ceramic particle reinforced metal matrix composite material is 3mm, ceramic The particle size of the particles is 80 mesh. The volume of ceramic particles in the ceramic particle reinforced metal matrix composite material accounts for 51%, and the remaining volume is the same metal matrix as the existing zinc ingot mold metal material; the ceramic particles are SiC, and the metal matrix is cast iron. (specifically HT200 cast iron).

[0034] The preparation method of this above-mentioned composite material zinc ingot mould, its concrete steps are as follows:

[0035] Step 1: Mix the ceramic particles and the binder in a ball mill for 60 minutes and then sieve it, press it into a triangular preform under a p...

Embodiment 3

[0040] Such as Figures 1 to 3As shown, the composite material zinc ingot mold, the composite material zinc ingot mold is covered with layered ceramic particle reinforced metal matrix composite material on the surface of the existing zinc ingot mold, the thickness of the ceramic particle reinforced metal matrix composite material is 2mm, ceramic The particle size is 120 mesh. The volume of ceramic particles in the ceramic particle reinforced metal matrix composite material accounts for 56%, and the remaining volume is the same metal matrix as the existing zinc ingot mold metal material; the mass ratio of ceramic particles is 7:3 TiN and Si 3 N 4 Mixture, the metal base is cast iron (specifically QT400-18 cast iron).

[0041] The preparation method of this above-mentioned composite material zinc ingot mould, its concrete steps are as follows:

[0042] Step 1: Mix the ceramic particles and the binder in a ball mill for 120 minutes, then sieve, and press it into a triangular p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com