A Metal/Ceramic Layered Composite Internal Heater

A composite material and inner heater technology, applied in the direction of the heating element shape and other directions, can solve the problems of reducing the brittleness of the ceramic inner heater, unable to make a large-sized outer casing, difficult to process and manufacture ceramics, etc., and achieve good resistance to zinc liquid corrosion. , Easy to install, not easy to zinc slag effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

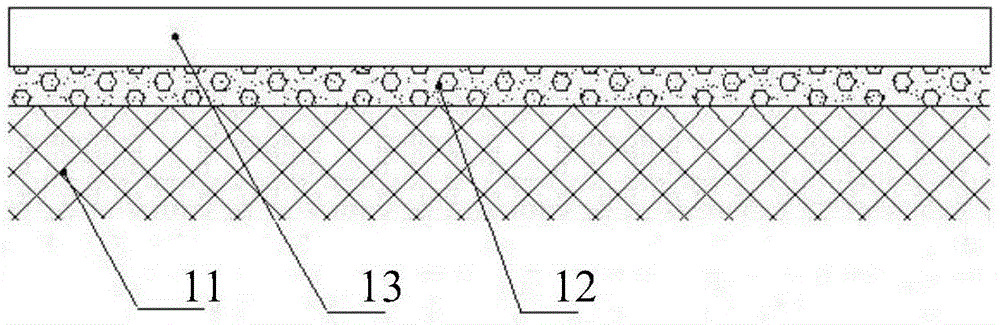

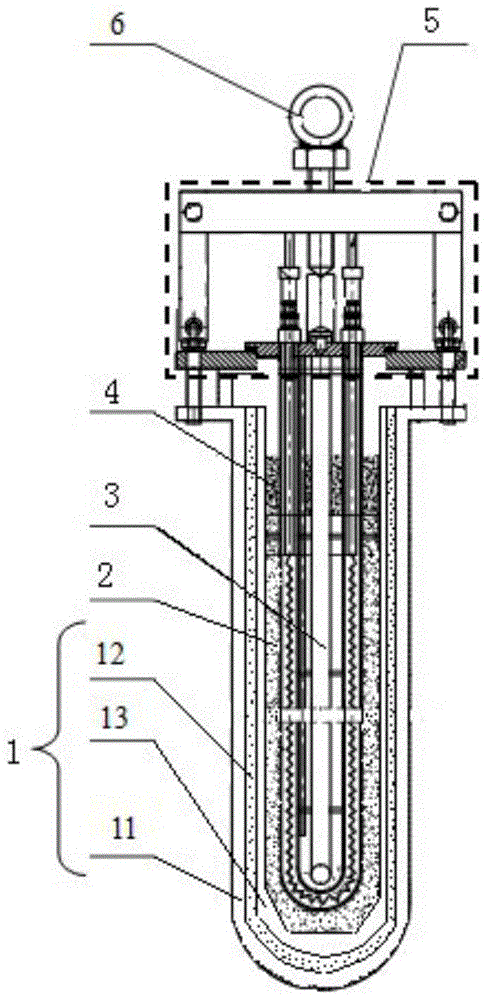

[0029] This embodiment adopts the above-mentioned preparation method and assembly process. The outer casing 1 of the heater in this embodiment is cylindrical with the bottom end sealed and the upper end open; the ceramic layer 11 is made of silicon carbide, and its length is 1000mm, the inner diameter is 130mm, and the wall thickness is 20mm; the metal layer 13 is made of stainless steel pipe , the length of the stainless steel tube is 972mm, the inner diameter is 120mm, and the thickness is 4mm. The mass percent composition of the bonding alloy 12 is Al: 75%, Ti: 5%, Cu8%, Si: 12%; the bonding alloy 12 is a solid-liquid two-phase at the service temperature, and the thickness of the bonding alloy layer 12 is 2mm. The heating core 3 is composed of four sets of U-shaped electric heating tubes, 6 partitions are evenly distributed on the heating core, and the antioxidant 4 is in the form of nano-scale powder.

[0030] Add 7.5kg of pure aluminum to a crucible boiler in a nitrogen...

Embodiment 2

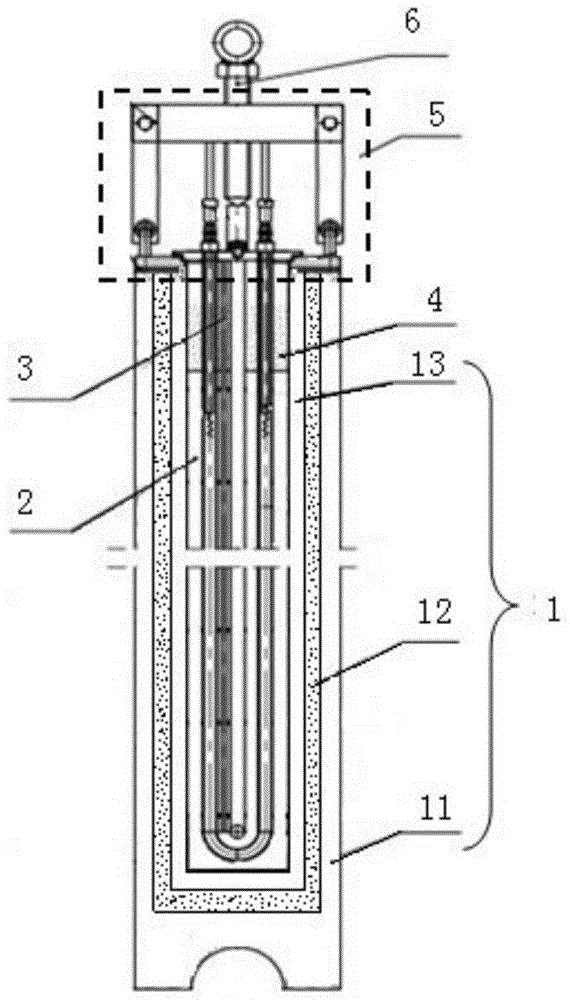

[0040] This embodiment adopts the above-mentioned preparation method and assembly process. In the present embodiment, the outer sleeve 1 of the heater is a cuboid whose bottom end seals the upper end opening (see image 3 ); the ceramic layer 11 is made of silicon nitride, its length is 1800mm, its inner diameter is 200mm, and its wall thickness is 20mm; the metal layer 13 is made of carbon steel, its length is 1772mm, its inner diameter is 182mm, and its thickness is 4mm. The mass percentage composition of the bonding alloy 12 is Al: 68%, Ti: 10%, Cu8%, Si: 14%; the thickness of the bonding alloy layer 12 is 10 mm. The antioxidant 4 is nano-scale powder, and the heating core 3 is composed of six sets of U-shaped electric heating tubes.

Embodiment 3

[0042] This embodiment adopts the above-mentioned preparation method and assembly process. The outer casing 1 of the heater in this embodiment is a cuboid whose bottom end is sealed and the upper end is open; the ceramic layer 11 is made of alumina ceramic material, and its length is 1500mm, the inner diameter is 160mm, and the wall thickness is 20mm; the metal layer 13 is made of carbon steel Made of carbon steel, the length is 1482mm, the inner diameter is 150mm, and the thickness is 4mm. The mass percentage composition of the bonding alloy 12 is Al: 83%, Ti: 5%, Cu3%, Si: 9%; the thickness of the bonding alloy layer 12 is 2.5 mm. The antioxidant 4 is a nanoscale powder, and the heating core 3 is composed of four sets of U-shaped electric heating tubes.

[0043] The bonding alloy 12 in embodiment 1, embodiment 2 and embodiment 3 are all solid-liquid two phases at the service temperature, the volume ratio of solid phase is 60-80%, the high melting point phase of bonding allo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com